They shipped me three really separate things.

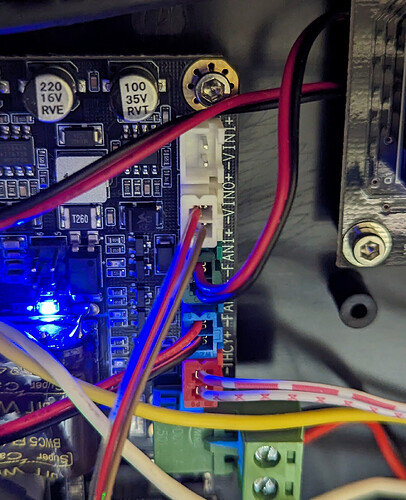

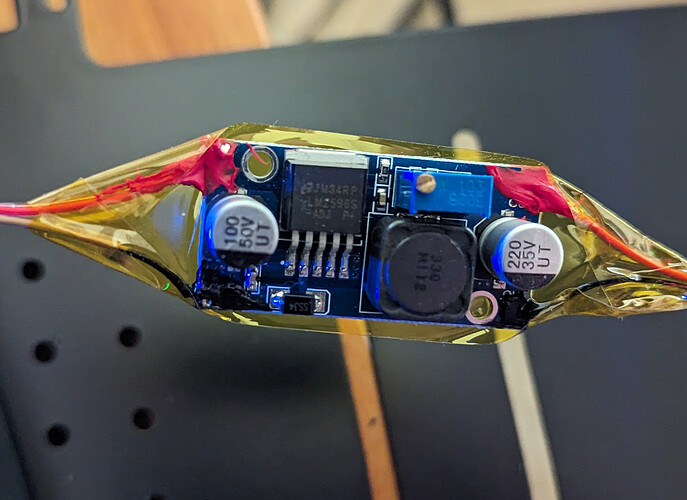

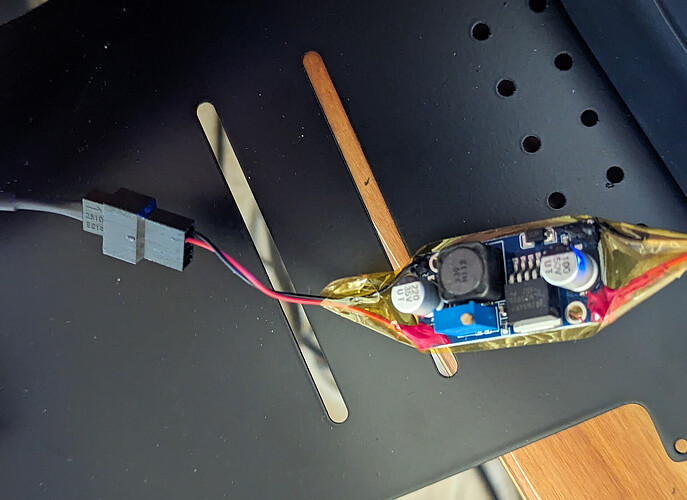

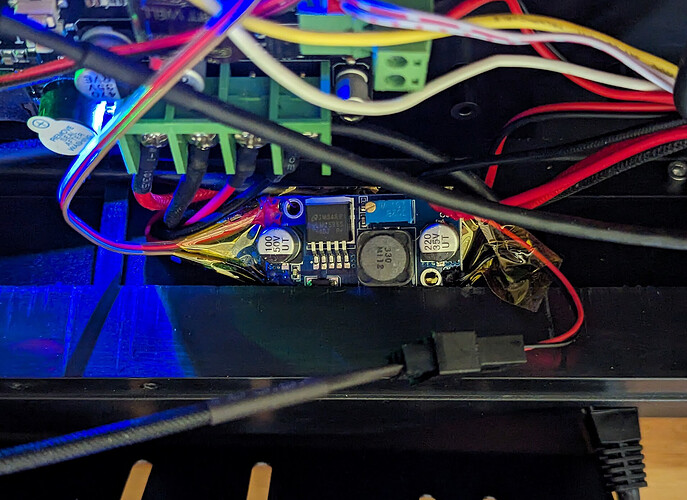

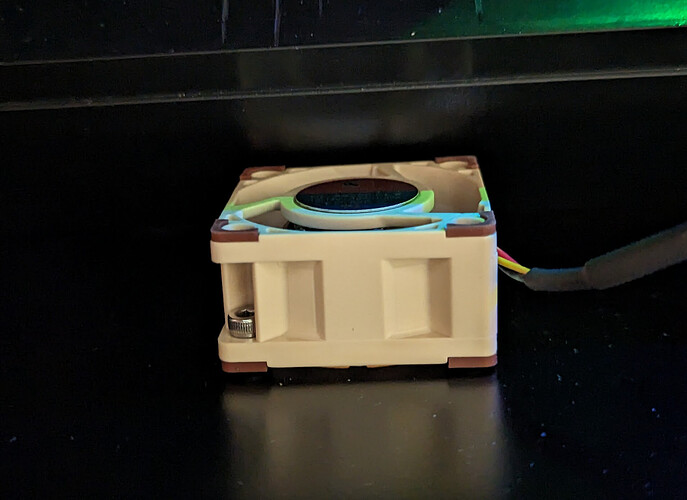

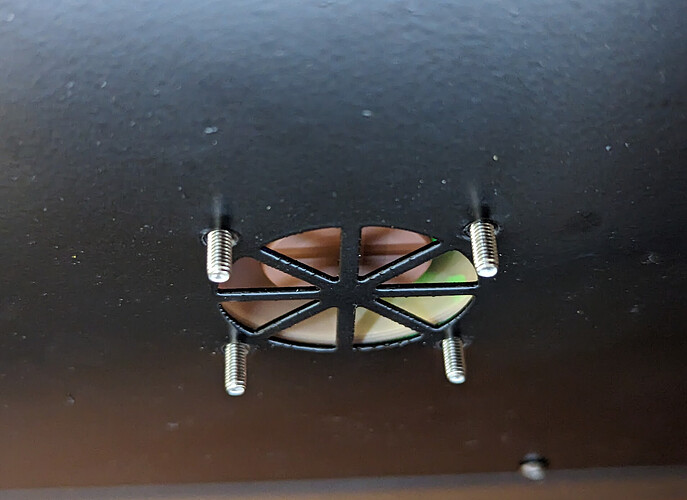

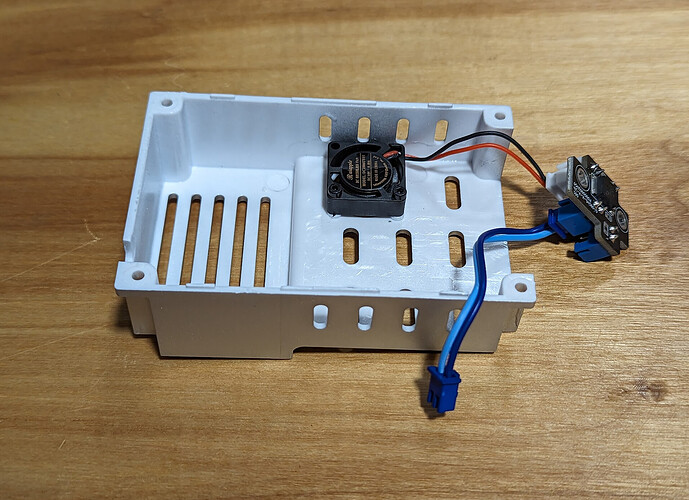

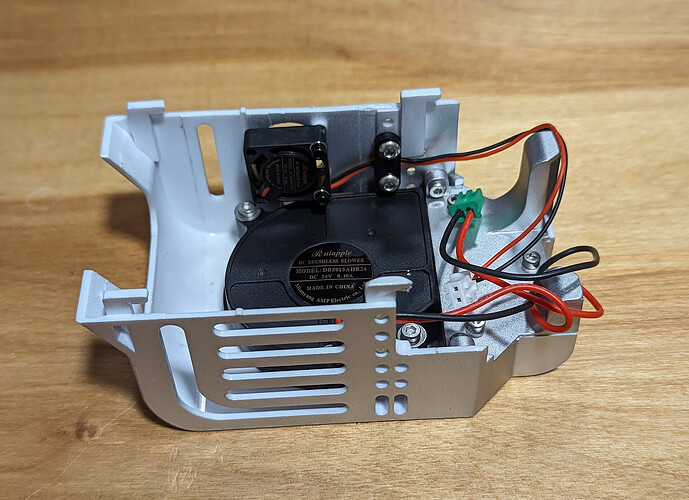

A new front and back cover, which have more air slots and each have a tiny 20mm 5V fan. This includes a breakout board with a regulator to power them from the same circuit as the 24V heat sink cooling fan. There were already unpopulated holes for adding this breakout board. I guess they had planned ahead to have room for a fix for something?

This I installed, and re-ran input calibration since I clearly changed the mass of the print head.

It was nice to get a new front cover, since one of the four tangs on the original cover had already broken.

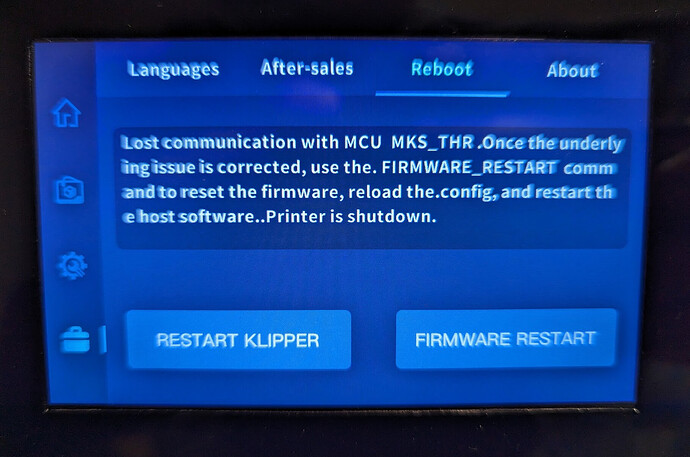

A new USB-C cable (over which they run CAN) and installation hardware for it. Interestingly, they must have tested and bought some off-the-shelf cable, because both ends are clearly hand-trimmed to fit.

For this, I am waiting to see whether I keep getting the error before taking the effort to install it. If I do keep seeing it, my USB-C cable is probably defective. But it’s rather a pain to route through and install, and since I normally got that error message with the printer at rest rather than during a print, I doubt that the cable is the problem. For this, I’ll wait and see.

An inductive bed leveling sensor and a soft magnetic bed since the 9 hard high-temperature magnets would make the inductive sensor not work. They said that it’s more robust than the bltouch. However, I already bought a spare bltouch just in case this one breaks, I want to be able to swap out surfaces without having to have different profiles for different surfaces, and I don’t want to add a soft magnetic surface when they already ship high-temperature magnets. In fact, I’ve been pondering changing my other printer over from an inductive print head to a bltouch after experiencing failure of an inductive sensor, and in doing so I would also like to change from soft magnetic sheet to hi-temp rare earth magnets.

Fortunately, the new cover with the new fans still fits around the bltouch, so I’ll keep the soft magnetic sheet and inductive sensor aside for now. If I go through two bltouch sensors, I can always reconsider.

This does make me assume that they have switched to shipping new units with the inductive sensor.