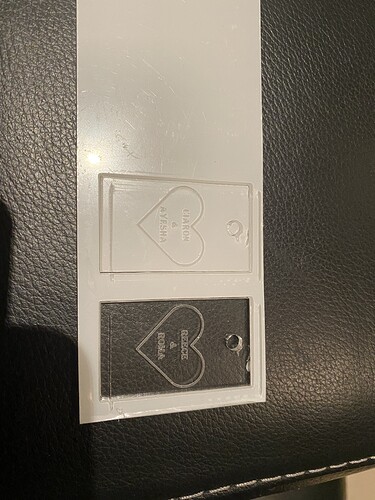

Per the attached pics, I seem to be getting an extra cut line at each side of the perspex while vector cutting. I kept the protective layer on to prevent the smoke marks but on the left and right sides of the cut (the short sides of the object) you will see that there was an extra cut to the left of the intended cut on each side. These were the vertical lines on the acrylic sheet. The line width for the vector cut I had was 0.518mm. I used 10mm/sec and 2 passes at 30% to actually get the laser to cut through the 3mm thick acrylic and protective layer on each side. It’s strange that it only seems to be double cutting on the short sides. You will see that the raster engrave within the object was fine. I don’t see this double or split on anything else I have been engraving. This is just happening with the cut on 2 side.

Could you share the file your are using?

Hmmm…I opened the file in inkscape and don’t see anything obvious. I’m not a K40 whisperer using, but is it possible you have more than 1 image file loaded in whisperer? Any thoughts @Jammy?

as far as I know I haven’t multiple images loaded in whisperer. I didn’t think you could do that anyway.

I’ll take a look…

That is odd. Can’t see anything wrong with the image either.

The lines are also offset on the x and y.

Have you go the same cut depth on the X axis (the long cuts) as the Y (proper short cuts) ?

I cut the objects out at once at 10mm/sec, as well as the small hole. I needed 3 passes to do it due to the thickness and the protective layer. The ‘extra’ line obviously isn’t anywhere near as deep as the intended lines but it still is visible.

Is the thickness of the vector cut line a factor?

Hi anyone got any more ideas? The mirrors seem aligned, this doesn’t happen for raster or vector engraves. Doesn’t happen along the horizontal, only the verticals. I checked the mirrors again, I tried reduced powers and obviously at very low power the 2nd lines don’t appear but it take multiple multiple cuts to cut the perspex. There is obviously something wrong but I just can’t figure it out.

Have you tried just cutting a square?

Does that do the same thing?

I will try a square in the morning thanks. Is there a reasoning behind why this might work? I also reduced the thickness of the line but it had no effect at all. It’s getting frustrating…

Just stabbing in the dark since nothing else worked.

I sometimes find that simplifying the job will lead to hints.

I looked at th previous thread, and in there I asked a question to which I didn’t see a clear answer:

Also:

I still think there’s a chance that you are getting a reflection from the beam hitting the inside of the nozzle, or something like that. Please upload here the result of four test fires:

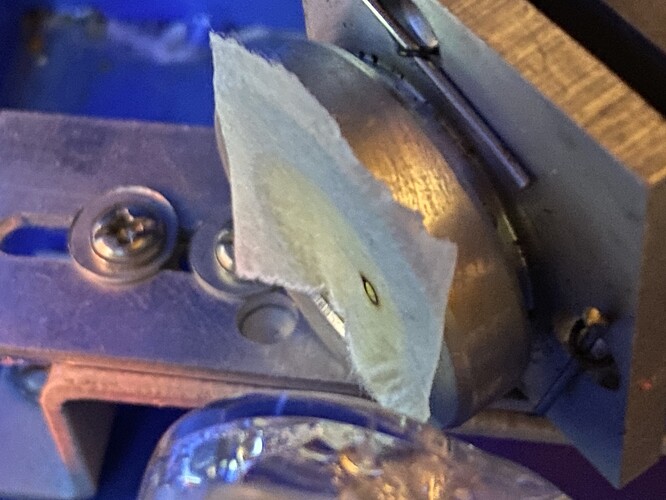

- picture of witness tape before first mirror

- picture of witness tape before second mirror

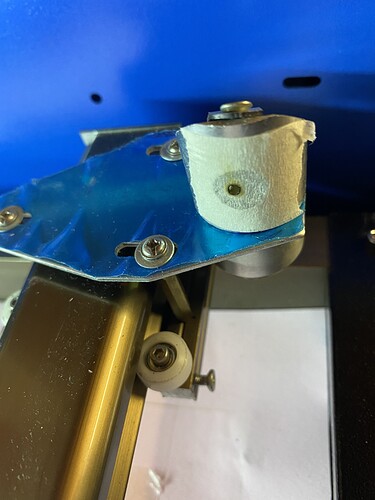

- picture of witness tape before head mirror

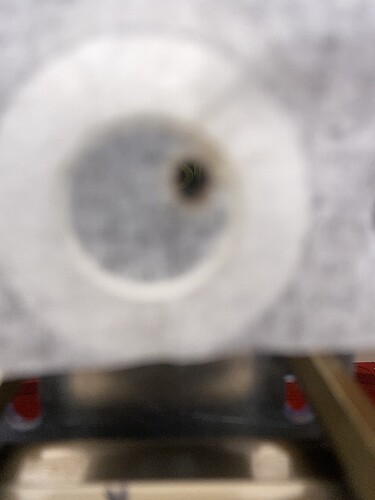

- picture of witness tape on the bottom of the tube, with the nozzle removed, and with the outline of the tube marked clearly

I agree this looks like a reflection from somewhere.

Thanks guys - I hope to get the masking tape tests done this evening and see where we go from there

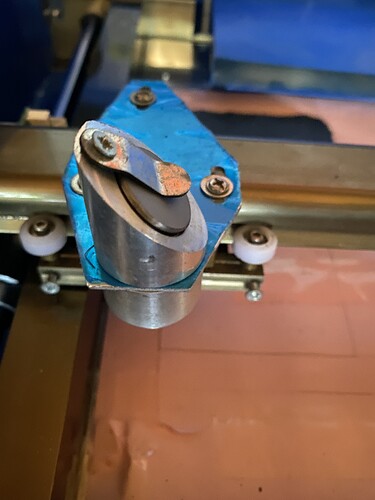

ok guys, seems to be a problem at the end a you had indicated. The pictures are in order. Mirror 1 seems centrerd, as does 2 and 3 but with the tape at the bottom of the head with the lens removed, it seems to be at close to the furthermost edge at the bottom right (forgive my hand drawn guide for the nozzle!!)

Mirror 1

Mirror 2

!

Mirror 3

!

Bottom of head with lens removed taken from below the nozzle in ‘selfie’/reverse mode. It seems to be at the edge of the nozzle but not touching

Actual tape when taken off and nozzle outlet hand drawn

!

Hey Mark

Mirror 1 looks out to me? Doesn’t look centered?

so I need to adjust the tube then? But if the other tests 2 are fine then is it not an issue with mirror 3? It def doesn’t seem to fit as snugly in the head than the previous.

Your mirror 3 is not adjustable, so you have to find where you need to hit mirror3 to go through the center of the nozzle. It may not be in the middle of the opening!

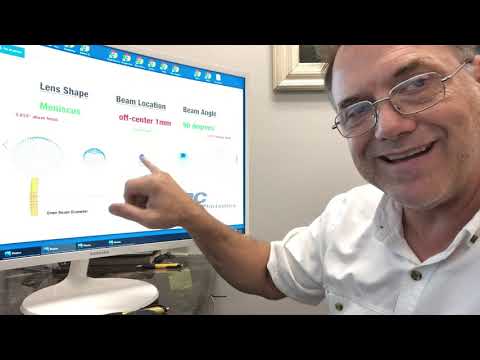

American Photonics has an alignment tool that may help you:

In particular, they have a video showing that in a particular K40 head they have (not the same one you have), aligning the beam with the center of the opening in the K40 head doesn’t cause the beam to align with the center of the nozzle.

You don’t have to buy the tool to understand the problem, but the tool isn’t expensive relative to the cost of making it and in this case it might make things a lot easier to get into alignment. I can recommend watching all four videos on the product page.

Fixing this will not only remove the ghosting but also give you a cleaner cut because the beam will be better focused. I don’t know the orientation of the offset; to the extent that it is front to back you can adjust mirror 2, but to the extent it is left to right you need to shift the beam path up and down (because 45° mirror).