the offset coming out of the nozzle is below and right of centre

“Below” depends on perspective so I don’t know whether you need to move the beam toward the front or the back. That will be adjusting the location of mirror 2, one way or the other.

Towards the right of the unit means that the beam enters the head too low. Moving it up makes it hit the mirror further to the left, which makes it exit the nozzle further to the left. So you need to shift the beam path up by the distance it is right of center.

Thanks. The beam is to the front right relative to the machine. So I’ll go play now with mirror 2

Yup, you’ll need mirror 2 shifted back by the distance your tube witness is off center.

For shifting the beam up, my laser is in cradles with screws for height adjustment. I think K40s don’t come with cradles with screws, so you probably have to shim it. I’ll leave it to those who actually have a K40 to help with that part!

Are we ignoring this:

I don’t think we are. I wouldn’t expect sliding around on the registration face slightly (due to slightly smaller diameter?) to have this impact on alignment. I could be wrong but I was at least not ignoring it. (If it’s loose it might well also need to be tightened somehow, like if the clip got stretched.)

Does this head have any possibility for false registration for the mirror, such that the mirror could be mounted at a tilt?

The beam needs to be in the center of the first mirror.

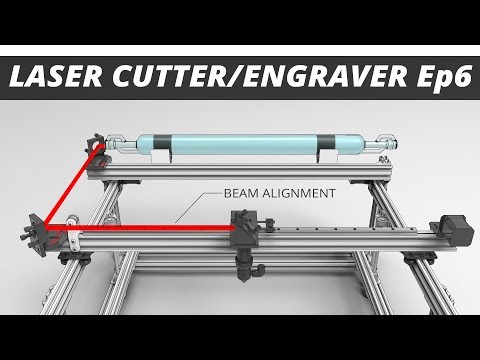

My guess is that the beam is not running parallel to the gantries X & Y axis as it traverses from mirror to mirror.

When the beam is far off from the gantries axis it’s a hard thing to see just looking at the placement of the beam on the mirrors. It’s a 3D problem.

What happens is the angle of the beam entering the mirror is wrong and then you adjust the next mirror to compensate for it. By the time you get to the non-adjustable mirror 3 it’s entering that mirror at an angle and the reciprocal of that angle causes the beam to hit the lens off-center which causes it to exit the lens at an angle. If it’s bad enough it hits the side of the nozzle.

There is not much room in the nozzle so it often reflects energy off the side. Consider that the beam is not a perfectly round cylinder of energy. It is gaussian so it has some power in the tails of that distribution that can be reflected from any surface that does not absorb all the energy. Even if the center of the beam does not hit the side wall the tails of energy might cause a reflection.

The beam has to enter mirror 3 parallel to the X-axis and at a right angle to the Y-axis hitting that mirror slightly off-center so that it will fold at exactly 90 degrees or perpendicular to the bed.

You can test to see if the beam is exiting perpendicular to the bed using this method.

- Tape a target to the bed.

- Set the bed a focal length

- Fire at the target

- Move the bed down 1/4"

- Fire again

If the marks on the target move relative to each other the beam are exiting the head at an angle.

Note: if the bed is not kept perpendicular to the gantry as you move it down this could also be a source of error but that is not usually a problem.

Profiling the entire path.

I dealt with this overall problem on my machine some time ago by making sliding targets aligned to the gantry so that I could accurately profile the beam as it traversed the X & Y.

There may be a simpler way to try this:

You can try this and it occurs to me as I am thinking about this problem that this same method could just use a piece of stiff graph paper held in a consistent reference to the gantry. This template is not as accurate as the acrylic tools but probably good enough to see a big problem.

This target would be placed and held vertically at various positions along the beam path and test-fires would be performed over the top of each other at positions between the mirrors. The result is that you could see how the beam moves along the path in X and Y relative to the gantry.

This attachment can be printed 1-1 on stiff card stock (or glued to something stiff) cut out and then used as described above.

This template mimics the dimensions of my tool. The circle is the region that the beam should be in. It can only be used for the path from mirror 1 to mirror two. If the laser is not parallel to the gantry axis it will likely show it along that path. I will create a second template for the x later today.

EDIT added the X template. I did not dimension this one but you can print it 1-1.

Note: I have not tested these templates.

K40 3D alignment target.pdf (793.3 KB)

XAxis3DAlignmentTarget.pdf (719.0 KB)

Thanks for this again. I think I may start again and look to get the laser exactly in the middle of the first mirror by somehow adjusting the actual tube? And then take things form there?

I’m starting to lose the will to live  I tried realigning the mirrors from the beginning again and now I have near a total loss of power at the lens. What was engraving slate before @20% won’t even now at 30%+…

I tried realigning the mirrors from the beginning again and now I have near a total loss of power at the lens. What was engraving slate before @20% won’t even now at 30%+…

Hang in there! Sometimes getting the optics right is a real challenge and very frustrating.

It would be most helpful if you show us pictures of your burned targets on each mirror.

Also, did you try this test?

Test to determine if the beam through the head is perpendicular to the bed.

Do this:

- Tape a target to the bed under the head.

- Set the bed at the proper focal length for the lense

- Fire at the target

- Move the bed down 1/4"

- Fire again

- Repeat a few times

Are the dots on the target on top of each other as you move the bed down?? Y/N?

Post a picture of your target.

unfortunately I don’t have a moving bed. It is fixed. I will get back to the machine in a little when I have calmed down  and take pics. I adjusted mirror 1 (physically moved it a few mm toward the back of the machine to try and get the initial laser beam more toward the centre. The spots on mirror 2 both at the closest point to mirror 1 and farthest point were both on top of each other and centre. Likewise with the 2 spots on the head unit (albeit a tiny fraction below centre). the beam def comes out through the lens as a test fire will burn masking tape. But there is obviously something going badly wrong!! Beforehand, I could engrave slate at between 15%-20% but now it will hardly mark at 30% and much higher. I have left it for a while and will get back to it with a clear head when I can. Update - Now, in saying that, it looks like the beam hitting mirror 1, although centred, is a little high. But I have no way of lowering the laser tube.

and take pics. I adjusted mirror 1 (physically moved it a few mm toward the back of the machine to try and get the initial laser beam more toward the centre. The spots on mirror 2 both at the closest point to mirror 1 and farthest point were both on top of each other and centre. Likewise with the 2 spots on the head unit (albeit a tiny fraction below centre). the beam def comes out through the lens as a test fire will burn masking tape. But there is obviously something going badly wrong!! Beforehand, I could engrave slate at between 15%-20% but now it will hardly mark at 30% and much higher. I have left it for a while and will get back to it with a clear head when I can. Update - Now, in saying that, it looks like the beam hitting mirror 1, although centred, is a little high. But I have no way of lowering the laser tube.

I think we can still do this test if we are a bit creative

You can try a Jenga approach ![]() …

…

- Get a hand full of the same thickness and size materials say 1" square, 1/4 thick.

- With double-back tape stick a spacer block under the head to the floor of the K40.

- On top of the bottom spacer stack the rest of the squares each one lined up with the stack below it. [If you have something that is square you can use it set on its edge to ensure the stack is perpendicular.]

- When this is set up correctly the target square on top of the stack of squares should be near the FL of the head

Fix the target to the top square

- Put the targeted square on top and align it perpendicular to the stack below it.

- Fire the laser

- Pull the square under the top one out, go to step 1

- Repeat 1-3 a few times

I would be content to get back to where I was before at the present moment (meaning where I was at the top of this post!!) The perpendicular job alignment would be the bonus

first, I’ll show pics of the mirror alignment and burning

I’m giving the machine a ‘rest’ as well in the hope that it will behave much better when I get back

Just to be clear:

This bed move test is not to ensure that the “job is aligned” and is essential to understanding your problem. It is to prove that there is a reflection [or now a blockage] in the head.

If the beam is hitting the center of each of mirrors 1 and 2 and enters the center of mirror 3’s housing then the beam is somehow losing power by interference or reflection in the head.

Your realignment may have exacerbated a reflection problem at the head and now is actually attenuating the beam.

Can you post pictures of your mirror 3 and lens? Have you looked at their surfaces for dirt, damage, or cracks?

You can also look at the inside of the head’s tube to see if there are any burn marks.

When we ask for dead center of the mirrors, we should not forget the paralax error caused from the mirrors 1 and 2 beeing ~2mm behind the sticky tape! So on the tape, the burn mark shoud be in the vertical center and a bit right of the center.

Be aware that the beam diameter is about 2-5mm, even if the burned dot is only 1mm. This is just the highest energy at the center.

- For correcting the position on mirror 1 you don’t need to move the laser tube, you can just move the mirror holder (not adjust the mirror) a bit to the back.

- After that, you shuld just try to adjust mirror 1 to get the beam parallel to the y axis, so that a shoot with the gantry in the back and in the front does hit the exact same position on mirror 2 (anywhere on the tape, doesn’t need to be the center of mirror 2).

- Move mirror 2 so the dot hits in the center of mirror 2.

- Adjust mirror 2 so the beam is exactly parallel to the x axis.

- To get the beam to the center of mirror 3, you usually would move mirror 3, but this is not possible on a k40, so you have to move (not ajust) mirror 2 and repeat from step 4.

Watch this video for a better understanding:

Guys, THANKS for everything. I made possibly the most rudimentary error!! Mirror 2 was stained form all the aligning with the tape from the smoke marks from the tape. I was SO confused that the burn marks were as close to perfect on the tape on mirror 2 and then the issues arose after that. I found that to get a burn mark on the entry to mirror 3 was getting more difficult and then WOW, Archimedes moment!! Eureka!! I checked mirror 2 and it was dirty. Cleaned it, made a few more minor adjustments and hey presto - it was much better than the old tube and better than before. My time away from the machine today gave us both time to calm down and regroup!!

So is this solved and can you summarize what the problem/solution was so that we can call it solved.

Yes, for this particular issue, I needed to adjust mirror 1 so that the new tube beam hit more toward the centre. To do this, I needed to physically move the complete mirror (unit and mirror) back 1-2mm. Then I needed to realign all the mirrors but th main issue was CLEAN the mirrors due to the smoke stains from the masking tape after multiple laser test fires during alignment. Thanks to all on here that assisted. I, no doubt, will require your services again!!

So there is no longer a double cut?

no, the vector cutting issue has now gone and the lines cut straight and true where they are intended!