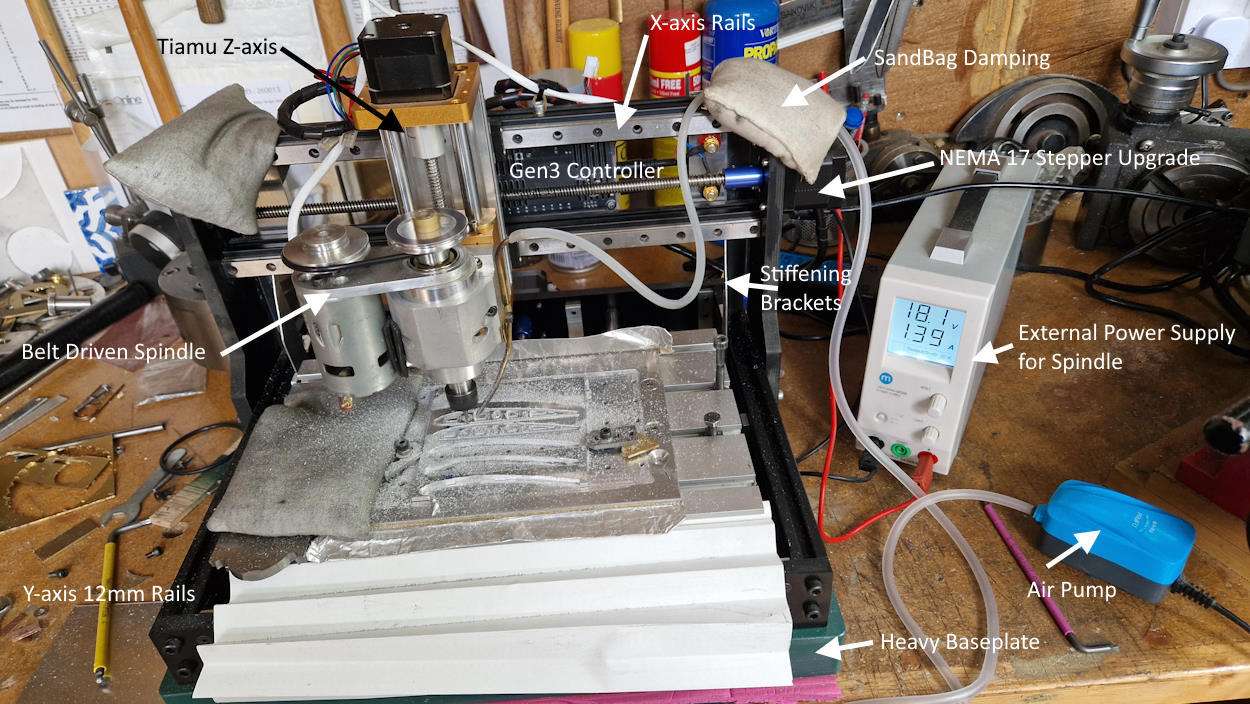

Wow basically built a whole new machine! All kinds of mods.

Unfortunately the one monkey wrench I have to throw in here. I tried to get some help maybe 2 years ago in compiling data on stepper motors. No one would try, too many motors, too much data, and most assumed the drivers magically fixed everything.

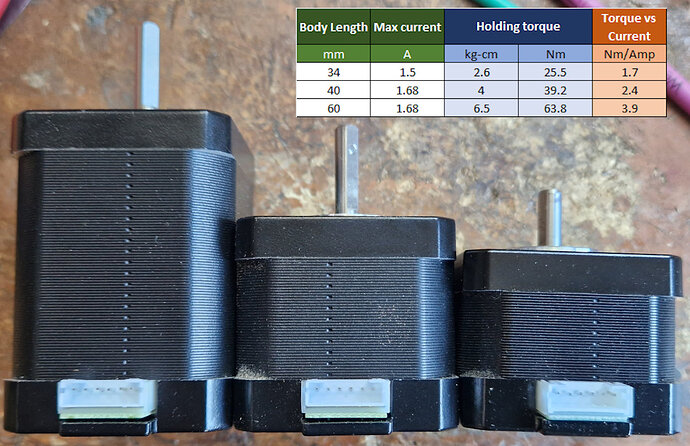

Lesson 1: Steppers are as varied as there are kinds of FDM filament or maybe better yet hairs on a cat. So while you can develop math to verify specs, and even fill in missing details needed to run good comparisons. -Consider that you can have a High Torque and a High Speed stepper sitting side by side and you would never know without specs or testing. But really, most are actually just cheep junk, and we don’t even know it thank to driver’s black magic.

Lesson 2: Consider that while yes drivers do kinda magically make it all work, most of the time, it’s really not working as well as we think. Based on the source voltage, onboard regulation, internal logic, load of the motor and a number of other factors… each type of driver has an optimal range. Often the motors run outside that range. This creates noise, heat or loss of torque. True what we get is good enough for MOST. But if you really want the best, pay very close attention to the details, the best operational range and matching Driver Motor pairs are tighter than most think.

For CNC you have to consider not just the Specs of the motor, the abilities of the driver, the ability of the chip-set driving the stepper and how loading the steppers effects -Everything.

I have been quietly trying to convince Marlin to add the option to include an I2C Ammeter to each channel so in CNC mode we can watch the loading of the Motors and even adjust the steppers as needed digital, from the firmware, or manually from the command line. Trinamic do some of that for us now, and Marlin even attempts to compensate for loading. But it is rudimentary.

I know I am not giving any specifics or math. I wish I had more to give, and the data I collected is pretty stale by now. But I hope my opinions help you to find even better stuff.

BTW, I have a 3018 too. Have only replaced the Controller, and power supply so far. Only just got it running the way I want, and am cutting parts for my gigantic FDM which needs a new display. Once the FDM is back up and running, unless life goes a different direction I will build a laser bend then a much larger CNC. I will need to be sure that the steppers I install match the optimal range for the load and voltage supported by the drivers as possible to get the best out of each of these machines.