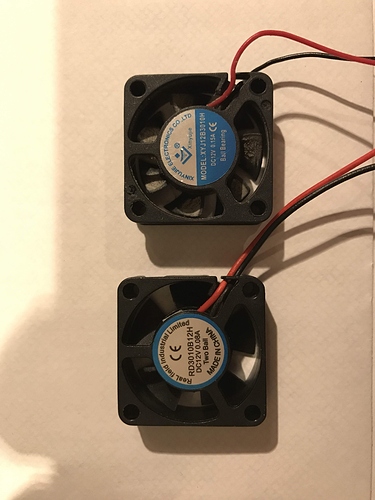

What’s the secret to obtaining quiet fans? On top you see the 7 bladed e3d fan. It’s quiet. Beneath is “some generic fan I got off AliExpress”…it sounds like a wailing banshee. It can’t just be the two extra blades, can it? And recently recommendations on how to obtain quality blowage?

I would say use a larger fan + adapter if you can. To move the same amount of air and keep up the pressure you need to spin the blades faster. More blades helps but ultimately the fan size does have a big impact.

I use 35mm squirrel cage blowers as I find they are much quieter and have a higher pressure but they don’t move as much air as axial fans if you run them side by side in the open.

Isnt there an option at least in Marlin to controll some of that noise from the fans?

If the fan header you plug it into can be PWM controlled then I don’t see why not. It depends on the control board design. You may need to reflash marlin or update an eeprom setting to use it though.

My point wasn’t that you could go larger to make it quieter, but that there was a clear quality/sound difference between two different makers. I’ve also found some fans do NOT like to be throttled back, making a nasty whine when you do so.

Yeah bad quality ones have similarly bad quality bronze bushings for the motor. Good quality 3010 fans use bearings not bushings. The problem is at 24V the selection is more limited than 12v.

My rule of thumb is wider blade angle more airflow, more blades (less space in between blades) more pressure. Just get some brand name industrial fans so you can read their datasheets. like sunnon kde series. sunon maglev kde1204pkv2 is the best for quietness and has 8cfm but its a 40x40x10mm. Also avoid ball bearing chinese fans, most of them suck.

Out of necessity, I found I could use a 12v Fan in a 24V system with an inline 160 Ohm (Brown Blue Brown Gold) Resistor.

You can use the controller to “pull down” a device that uses a different voltage rail as a source. So the + side of a fan could be hooked to 12V, the - side connected to the - terminal of the FET output.

Number of blades is a factor in noise but there’s other factors. A cheap 7 blade 30x10 fan won’t necessarily be any different than a cheap 5 blade 30x10 fan. I like to go with a larger fan if I can, as quiet one as possible that still exceeds the static pressure and rated flow as the fan being replaced.

Fan noise is mostly a matter of RPM. Slower fans are quieter. A slower fan needs more blades at a steeper pitch and more current to push the same air.

Other stuff like bearing and electronics quality also matters, but RPM is the biggest one.

It may be that given the number of noise producing functions and issues a 3d printer has, chasing individual parts noise production is going to be far less effective than simply putting it in a sound dampening enclosure. I ignore everything but print quality and smooth function, I ask a lot of a printer, being quiet seems like it is to much and will conflict with other demands so I put that on a separate device to achieve it if needed. Simple foam core box enclosure to stop drafts with ABS and I cannot hear my i3 at all, I had to make one side acrylic just to see if it’s running, though it does print fairly quiet anyway since it’s slow.

quiet? I can hear my e3d fan from up the other end of the house, it sounds like a vacuum cleaner

Lol

If noise level and performance are the main criteria, I would send $6.99 to Filastruder - they have both 12v and 24v versions…

There is a lot of engineering that goes into designing a quiet fan, as the ballance of airflow and noise involves a lot more than just the speed and number of blades. E3d is willing to expend the effort, Chinese clone companies aren’t.

@William_Eades it’s not like E3D is designing their own fans. They just pick one from a catalog. You can get on Digikey or other major parts vendor and the dB level is listed for most of the fans.

Whether they design it themselves or outsource it, they choose to use a well designed unit which will cost you a little more.

AFAIK there are 3 methods to mount the blade onto the base. There are sleeve-bearings, fluid-bearing and ball-bearings (or even better double-ball-bearings). The cheap and often bought “chinese”-ones have the cheap sleeve bearing. While the fluid-bearing ones are theoretically the best ones in the list, they actually aren’t because of our use-case. The fan is constantly moved around very rough (think about infill movement) so ball-bearing types are the best to use for us. But they are more expensive.

Bearings play a large part but there are also blade profile, cavitation, intake and exhaust area/restriction, RPM and venturi effect calculations that must be made and balanced to produce the most effecient fan for the money.

The 24v fans that came with my E3D hotends are just too loud. I’m willing to go bigger, also maybe I should go for 12v since there are more options.

Couldn’t I run the 24v fans on 12v? They won’t push as much air but I suppose it’s just necessary if you push the hotend to its max temps of 300C where max cooling is required?