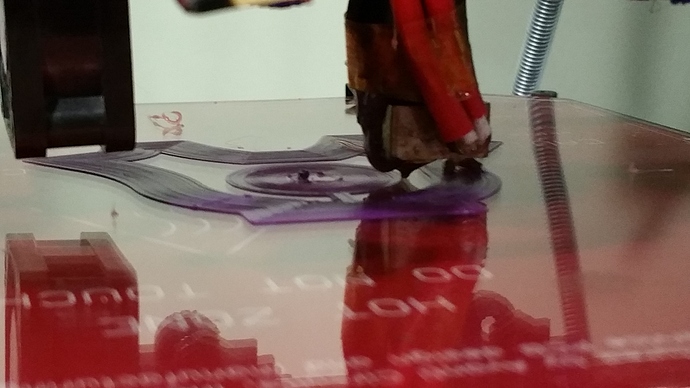

What is that nasty leak out of my side of hotend, I am using PLA. I changed to new spool but same effect.

Time for new hotend?

This is one old peek hotend, but had similar issue with other peek hotend and replace it because of leak too, but little smaller leak.

that is leaking PLA on thread… it was same color as filament - nvm time for new hotend

You have to make sure it’s sealed properly before you put the first plastic in it. Cheap no-name brands may never seal properly.

Most likely improperly tghtened nozzle. You’ll need to disassemble and clean out the nozzle, heater block and barrel.

Like others said, it’s most likely the nozzle not being tight but if the tolerances aren’t great it’s not gonna seal well period.

Have you tried wrapping it in in PTFE tape (Plumbers tape)? Works rather well and is cheap. But generally it is because the nozzle has come loose.

This is a J-head or copy of it. The idea of torquing the nozzle doesn’t apply in the same way as other hot ends because the nozzle is part of the heater block, and it threads into PEEK barrel. If that plastic is PLA, then I don’t know how it can be cleaned for reassembly.

You should torque it down while the nozzle is hot. Be careful, though, because it’s hot!

Also, no PTFE on all-metal hotends. Or rather, just no PTFE over 250C. To seal the all-metal you need the hotend heatbreak & nozzle to be nicely machined, flat and smooth.

Thank you for answers, I had that hotend laying for over a year and maybe time degrade sealing. got already 3 like that to fix up. seems like e3d lite is good alternative…

2nd the e3d lite idea

got them e3d (3mm) and e3d lite ordered - don’t tell my wife

After removing the hotend I noticed that brownish sticky substance by extruder (it is direct drive), so it was leaking out from top too? Strange

@Mateusz_Perlak I’ve had this on cheap Jhead clones which are missing the hollow nut at the top of the peek barrel. So the PTFE tube is not held tightly against the top of the heat break.

@Liam_Jackson I had 2 knockouts and one of them was leaking with the nut - I think that this sticky substance was blocking hotend hole and pressure forced it out on top. well got 3 total hotends to clean out. I suspect that termistor on one wasn’t measuring accurate and it went over 250C.