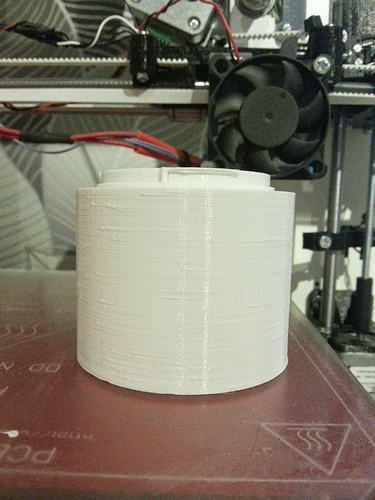

What is causing this bloobs? If I can make them go away my z is almost perfect!

(pla on my mendel90)

Unlike

I find that the blobs originate from where the head starts that bit of the wall. In Slic3r I’ve got the layer start set to random. If I turn random off, the blobs tend to line up (which looks worse).

Backpressure in you nozzle probably. Looks like you are using slic3r. Try increasing your retraction speed.

Or try Cura.

Could also be inconsistencies in the filament… But do try Cura. For a change I am getting good results from it…

Check the diameter of your filament. I had the same and noticed that my file and diameter was extremely inconsistent.

Thanks for the feedback! David and Tim is correct I’m running slic3r and random start. I will try cura and see if it goes away. If the filament is inconsistence how to I handle that? What is a good retraction speed on a wades geared 3mm?

The only way I found to compensate inconsistent filament diameter is… Change the filament

But when I look on your picture and hear that you use the random start point feature, I would also say that you should play around with the retraction speed an length.

But it’s always a good idea to check the quality (diameter) of the filament anyways

I’d say retract too. Try decreasing the retract length or playing with speed (i use 30 mm/s, start at 20 and increase it - there are wades that start jamming at 25, and wades that can handle 45 easily)

I fought this, and seems every other problem available, and found I was dragging nozzle. Fine most the time, but occasionally the build up would push and I would get this.

I fought this, and seems every other problem available, and found I was dragging nozzle. Fine most the time, but occasionally the build up would push and I would get this.

First try with cura looks promising, phone battery dead so no picture  . But i think cura used some wase mode (no retraction). Need to test more retraction! Brandon how did you solve that?

. But i think cura used some wase mode (no retraction). Need to test more retraction! Brandon how did you solve that?

I am a slic3r guy. So I actually use a set of feeler gauges to set my z height. Post that I will set z offset height in slic3r.

An example, I have been playing with a .25 nozzle. I level with a .05 feeler gauge and set z off set to .20. The bead lays down round not flat the first pass and only slightly gets flattened the second.

When the solid infill goes in it is smooth not raised. This is how I can verify I am set properly.

I’m still playing at this as I do get curling with heavy ABS applications, large print, .4 infill. But the sides of my print are smooth and beautiful… Comparable to the stratasys system I get to play with.

Hope this helps. Try it and let us know.