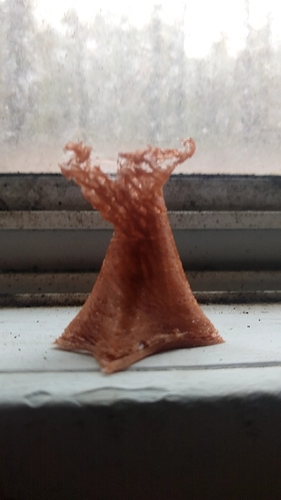

What am I doing wrong? I have an anet A8 and when I print I get this. It’s supposed to be a tree… The one on the right was coneing out better at 60% but got real messed up when it got into complicated work anyone know how to fix this?

Could you post an image of how it’s supposed to look?

It’s just a dead tree I was using as a test piece to try out the printer I usually stopped it at this point because it was so bad. as soon as it hits the lower limbs it gets real bad. The rest is rough at best. I had someone tell me that I should get better pla because I was using what came with the printer

What you see here is supposed to be the start of a solid branch coming out the side and a continuation of the tree trunk but it went all weird

It looks like you have under extrusion and possibly a lose sprocket on one of your steppers. Did you double check that everything is tight, calibrate your esteps and try printing again but slow it down to 20 mm print speed and see how it comes out

Gotcha. Cheap PLA is a possible culprit, but there are a lot of things that can cause this, most of which are hot-end related.

First, find yourself a calibration set. (Search Thingiverse - Thingiverse) a calibration set will help you diagnose these problems without long lag times between attempts, and without using too much filament.

Before replacing your filament:

Calibrate the feed rate of your filament and the temperature of your extruder. You can’t diagnose a problem if you don’t know where your starting point is.

Do several test prints within the temperature range specified for your filament. If you still can’t find a solution, then there are a few things you can look for.

Bad filament is rarely THAT bad out of the factory. You could still have dusty or water-logged filament if you haven’t been storing it in vacuum-packing or sealed boxes.

Water-logged filament doesn’t feel wet, it feels brittle. if you can’t bend a six inch piece of filament into a U without it snapping, then it’s water-logged) The occasional releases of steam will push divots into the extrusion, which will be visible on the surface, and the effect will increase over time.

Dirty filament will clog the extruder, causing it to under-extrude. If you can break apart layers in the lower portions (the ones that look solid) then it’s under-extruding. If your filament isn’t extruding fast enough, it won’t press into the previous layer and adhere to it. Layers will mis-align over time, and the upper layers will string all over the place. This can also happen if the temperature is too low or if the print speed is too slow, so rule that out by testing multiple temperature settings first.

If the temperature is too high or the printer is working too fast, the previous layers won’t drop below the “glass” temperature, and will be pushed out of the way by the next layer. This will mean that the following layer won’t have adequate adhesion surface, and will drag strings when it moves to the next layer.

If these tips don’t help, I suggest you look here:

https://www.simplify3d.com/support/print-quality-troubleshooting/

The heater block wasn’t reaching temp and when I went to remove it the tube broke… If I replaced the whole thing with a Titan extruder do u think I’ll save myself some headache

@chris_king I don’t know what you currently have, but switching to a Bowden style extruder was a game changer for me.

I just have a factory end