I’m sorry for the confusion about this. Through a friend, I bought it from a guy who hadn’t used it in over 2 years. He didn’t know anything about it and said that it was a K40. The one I have is here:

https://www.toolots.com/20-12-50w-co2-laser-engraver-and-cutter-usb-port-fda-certified-kehuilaser-kh-530.html?cid=1469602926&gclid=Cj0KCQiAsvTxBRDkARIsAH4W_j_C8TxPz0Tx9v1wW4CkgFxs7NE7V3JmKXOYaHeTA4yDYdhZNhJCUYkaAiQiEALw_wcB

On the unit itself, I don’t have a the power adjustment button nor is there a meter showing the power.

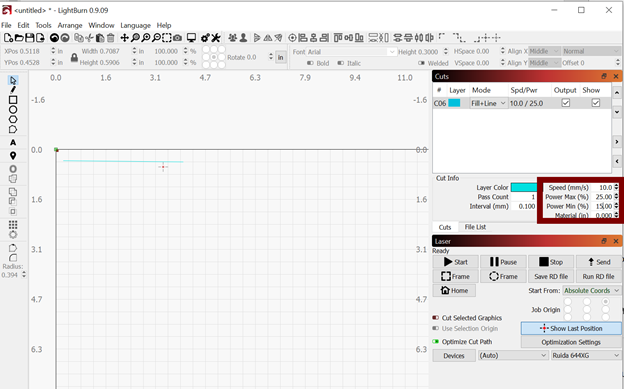

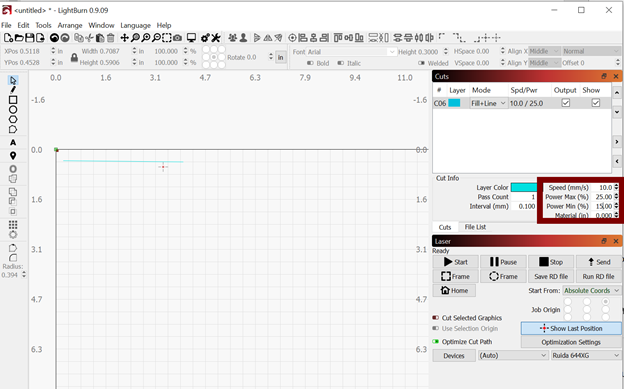

I have been using Lightburn and I was using it to control the speed and power. From my research, the ‘Max’ power is used for the majority of the time, but the ‘Min’ power is used in corners so the material doesn’t burn when the laser changes directions.

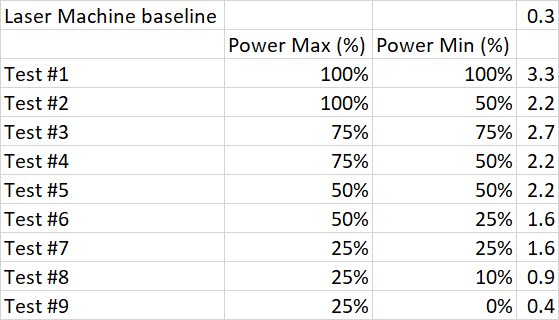

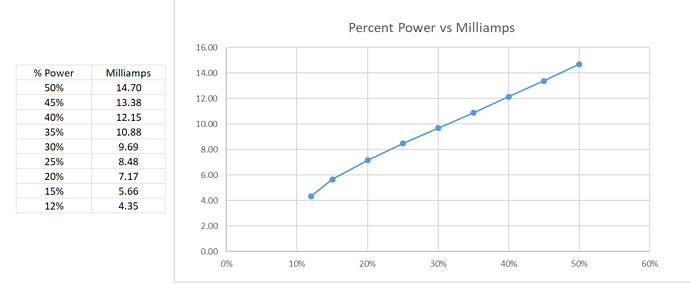

For the chart I made, I was using the power cord that goes into the entire unit, which includes the little LCD, external fan, gantry motors, and the C02 laser…. I used a clamp meter around the individual white power cord, the black and green cords were outside the clamp, I’m assuming the units are amps. But since I was measure a host of other items at the same time, I don’t think that it was a valid test. For comparison purposes, my wife’s hair dryer was 10.7 using the same clamp meter setting.

I’ll have to get my multimeter and put it just on the tube and make a chart of power setting vs tube current.

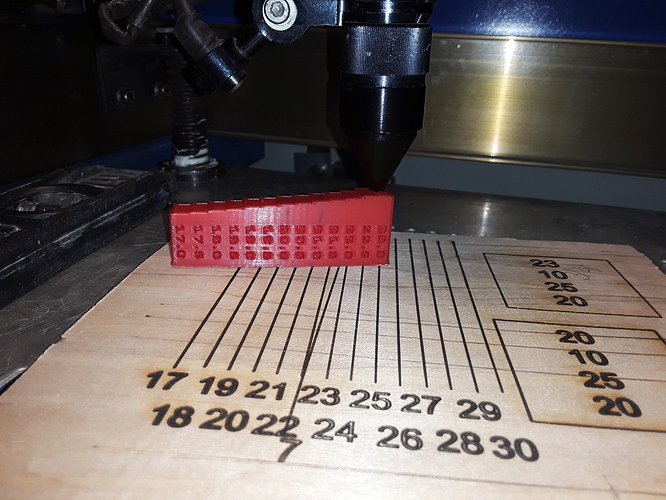

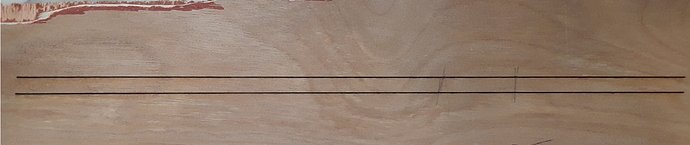

For the focal length test, originally I did the ramp test and saw where the line was the thinnest, it was somewhere around 24. To verify this, I did the lines at various heights and looked at the results. There was burning at the shorter distances and at the further distances it was more out of focus.

I’ll also take out the air assist nozzle and see if it has any effect.

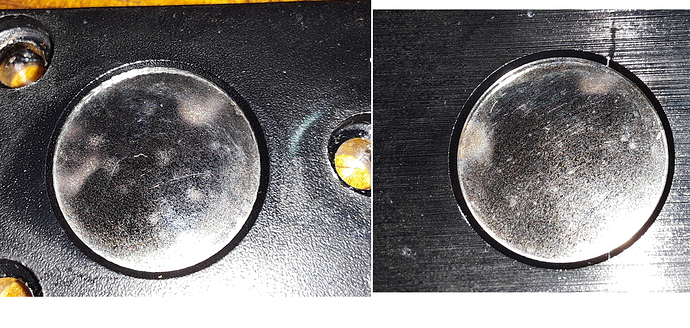

Here is the front and back of the focal lens. I didn’t see any burn marks, but there are some slight scratches on the concave side.