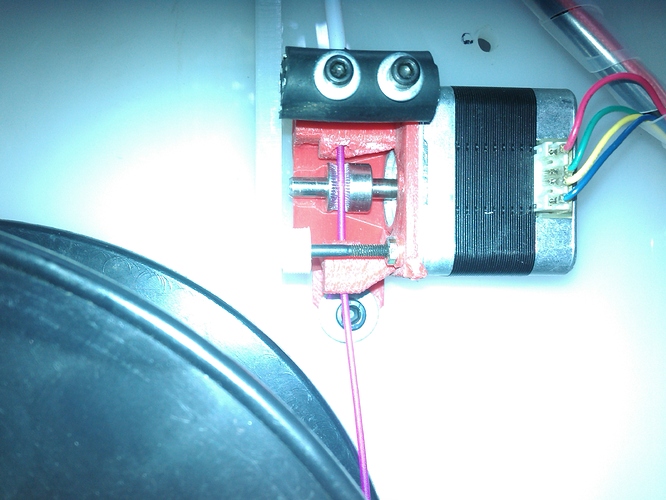

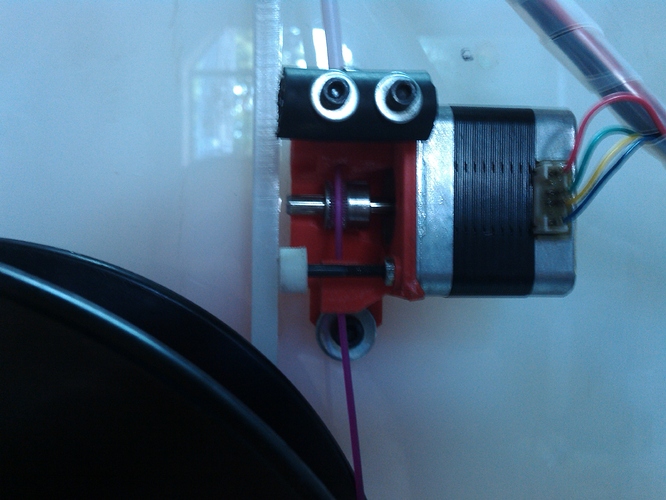

The filament has the same resistance when it enters the to e as when it goes through the hot end, not excessive. Can push by hand OK. But the drive gear will slip at any time. If there is more than 1 turn tight it will slip constantly. I have something not correct in the extruder. But not sure what. There is not that much there.

Is the drive gear slipping on the shaft of the stepper? You can flatten one side of the stepper shaft slightly.

Good idea. I put a felt marker on there to check it, but not the problem. I am thinking to try a different extruder. Seems like most people have good luck with this design tho.

‘slipping’ can be two or three things in my experience:

- is the motor getting enough current?

- is the tensioner tight enough (or too tight?)

- is the nozzle preventing filament from flowing due to temp (unlikely with firmware safeties), clogging, or build plate obstruction?

Mike Miller is right. #3 is unlikely because you can push filament through manually. If things were working ok before, I doubt the current has changed. So I would bet on the hobbed bolt being too tight or too loose.

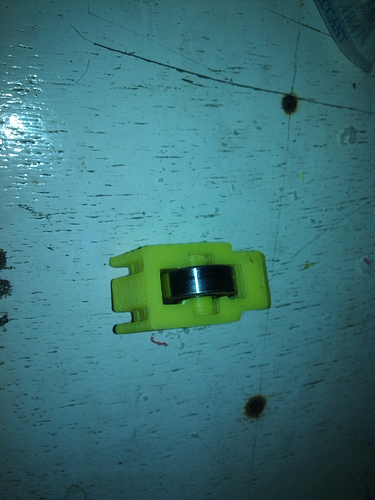

Looks like you have a printed pin supporting the roller bearing in the first pic. Should be a metal pin to give it a good backing. Your probably pinning the bearing against the back side of the bracket causing it to stop rolling which doesn’t allow the filement to properly feed through. Just a guess.

To address @Mike_Miller 's commend, your extruder is SLIPPING (drive gear keeps moving, but filament does not, so that the teeth of the drive gear grind the filament, also known as STRIPPING the filament), not SKIPPING (the drive gear maintains its grip on the filament, but the motor does not have enough torque to push it and skips steps), right?

@Ross_Shannon 's suggestion sounds like a likely cause to me.

I am actually thinking that your nozzle is partially blocked. You can try and clear it out with a 100C pullout.

have you tried springs instead of the rubber hose, depending on the rubber that may not give enough pressure to grip the filament.

+Peter van der Walt Nope not buckling.

@Mike_Miller @Dan_Kirkpatrick Motor has enough current .9 now on VREF, tension-er can only have 1 turn tension or it will skip even more, nozzle clogged is not the problem as i have removed the tube from the extruder to eliminate that issue.

@George_Moore Please see comments.

@RepRapPro.Me Please see the comments

@Ross_Shannon I am going to investigate this.

One thing that is different from my direct drive to this boden is the direct drive uses a 625 bearing. Boden uses a 608.

@Wayne_Friedt Is it skipping or slipping? Your last post said skipping, which is something entirely different from the question we’ve been trying to answer.

Sorry bout that. The filament is slipping, drive gear is slipping on the filament. No stepper skip.

Your fuel hose is too big. Use a smaller diameter and tighten that mofo up. I’m using the same airtripper at present, allthough it’s modified so the Bowden tube goes right into the housing and butts up against the drive wheel, so there’s no room for buckling.

Ah. You are also missing the small bearing that goes on the end of the drive shaft after the mk7, so nothing is preventing your drive shaft from flexing when you tension the idler.

@Tim_Rastall A direct-drive stepper motor should have two integrated bearings, so it would have to have enough force to bend the metal for that to happen.

@Whosa_whatsis perhaps so but the airtripper design does have an extra bearing to offset the pressure exerted by the idler.

@Tim_Rastall That’s because it’s also designed to be used with geared steppers, which usually have only one bearing on the output shaft from the gearbox and thus may bind without the second bearing.

Airtripper states the small front gear is not needed. Problem solved. I changed the printed axle to a 8mm metal one. The plastic one wasn’t deflecting causing the bearing to drag. When i printed it it wasn’t a completely straight column. It sort of dodged off it 2 directions causing the bearing to rock to one side. It was not pressing up agenst the drive gear square. Seems such a minor detail as you would think holding the filament tight agenst the MK7 would work in multiple directions because of the curved design.