Hello everyone, it has been quite a while since I have posted anything here.

I have an OpenBuilds Ox CNC router that I built a few years ago (~May 2015, I think) along with a TinyG v8 controller board to drive it. It was always painful to get it to finish a job because it always had halting issues. If it weren’t for me storing the offsets from home I would never have completed any jobs with it. Really, I only ever finished one or two small jobs on it.

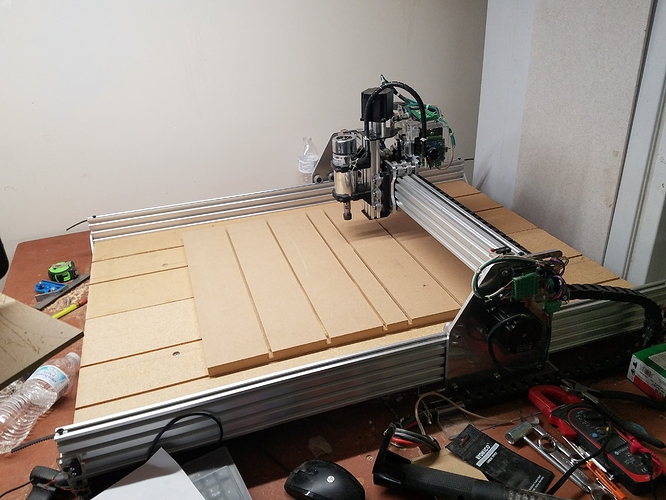

Well, the pandemic hit and with it came remodeling my house, which led to the garage getting stuffed. I have finally dug myself out of that hole and can even park my car in the garage. I built a couple of workbenches out of all of the scrap I had, and then created a permanent home for the Ox in the back corner.

Then I tried getting it going again. I have an old PC running Linux Mint and using CNC.js, which is what I was using before (except it was running Windows 7 before). Note that yes, I tried Chilipeppr, but it had other problems, like spawning a process then using the browser which had memory limitations, and halting issues, which lead me to CNC.js, which I have been quite happy with—except for the same job halting issues.

But, just like before, I am still getting strange behavior. I thought it might be a shielding problem, so I bought more shielded cable, only to find I had already checked that issue off my list years ago (it has shielded cabling, and a high-quality USB cable with a ferrite core).

Then, I went looking for configuration information on the TinyG v8, only to realize that this thing is pretty much done—nobody is really working on it anymore, and support is pretty much DIY.

Soooo…I’m looking for a new motion control system that will drive the 4 big NEMA23 steppers on this thing.

I see that OpenBuilds has a BlackBox Motion Control System X32 based on a 32-bit ARM CPU, which pairs with their own cross-platform control software, OpenBuilds Control. I downloaded and installed it on my Linux PC and it seems very much like CNC.js in that it has a lot of the same controls available. So, it seems like this would take a lot of the guesswork out of getting my Ox CNC back up and running. I also like that they have their own CAM software, too, OpenBuilds CAM. Although I haven’t tried it, it is comforting to know there is a one-stop shop for the motion controller hardware, controller software, and CAM software. If I can get it working with that, then maybe I’ll consider moving up to the more expensive CAM software, like VCarve or Aspire—but not before.

But, I have not seen much in the way of reviews of this controller, so I’m wondering if anybody here has tried it out?

Alternatively, is there any other system folks here would recommend for my OpenBuilds Ox CNC router?

(and thanks for reading this far—I just realized how much I typed)

BlackBox Motion Control System X32 (motion control hardware):

OpenBuilds Control (cross-platform host control software, Windows, Mac, Linux):

OpenBuilds CAM (a web-based application for converting SVG, DXF and Bitmap drawings, to GCODE for use with your CNC, Laser, Plasma or Dragknife Machine.): (looks like it has 4 g-code outputs, including Generic GRBL)