I’ve had a mill for a few years, and finally got to making a vise stop. I don’t really understand how I went this long without making it!

I finally realized that since I can screw the vice jaws either inside or outside, and that the outside position wouldn’t be necessary with a vice stop, I can use the screw holes for the outside jaw position to hold the back in place. It took measuring it a few times to be confident that the M10 holes were exactly 80mm on center, but the rest was pretty easy.

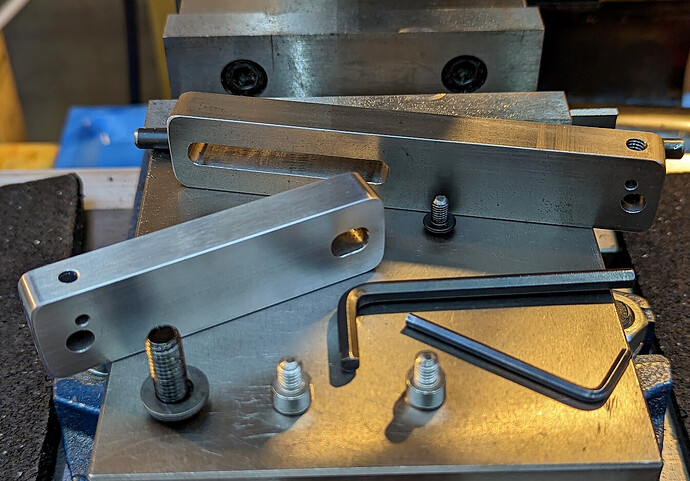

I cut a piece of 3/4" 1018 cold rolled mild steel, put 10mm holes through it, countersunk them, and use M10x30 countersunk screws to fix it to the back of the fixed jaw. I used countersunk screws so that the taper in the screws would locate the block without any chance of sliding around. I tapped both ends of the block M8.

Initially, I didn’t have a 0-flute chamfer bit large enough, so I used a 5-flute. That would have been OK, I think, in aluminum, but it sure chattered in steel!

I bought a 1" 0-flute chamfer bit, and brought the holes all the way to size — and quality!

Then I cut two arms out of 1/2" x 1" 1018 CRS; one short for when I need all the Y travel I can get, and one longer that can reach more positions for general use. I used the short arm while working on the long arm!

Blondihacks had quite the timely video to remind me how to mill slots:

I chain-drilled it and the cut a slot:

Except for one bobble at the end that doesn’t matter, that slot looks pretty good to me!

I cut 1/4" and 3mm rods, and rounded off the ends of screws to hold the rods in place. Initially, I used an old M8 screw I had in my M8 recycle drawer to hold the arms to the back piece. Here’s a family photo partway through:

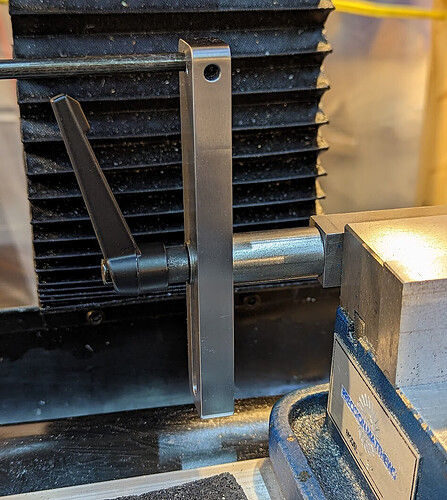

I measured the longest spare M8 kipp handle I own, and cut a 35mm long spacer, with ends face flat, bored 5/8" (a nice close fit on M8 hardware), to hold the arm away from the vise in normal use. If I ever need the arm to be right next to the vise, I can just swap the spacer and the arm.

When I’m not using it, it will probably be nicely out of the way most of the time back like this, without having to remove it from the vise.

I waited far too long to make this, and am so happy to have it in place. This would have been great to have while making More intransitive dice: Machining precision mathematical toys instead of using superglue to fix a scrap to the back jaw. I dislike cleaning off superglue!