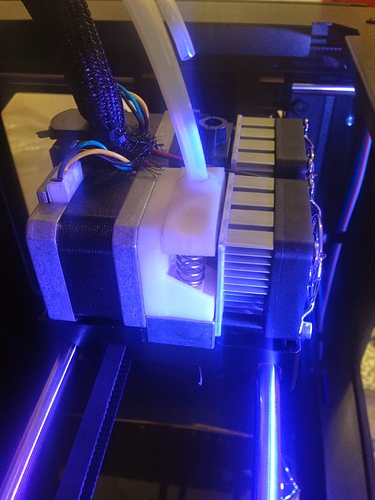

I upgraded my Replicator 2X with spring loaded extruder (http://www.thingiverse.com/thing:222667). It prints great Ninjaflex. I have a small problem though. When I get to printing something with slightest angle I get a very bad quality (small bulbs all over the print). Any Ideas?

I upgraded my Replicator 2X with spring loaded extruder ( http://www.thingiverse.com/thing:222667 ).

Pics of the prints would be helpful, that could be a number of things.

1st to mind though is over extrusion.

Did that work for you? I upgraded the Makerbot Replicator 2X at work and it wouldn’t extrude at all unless I pulled up where the spring was (as if the spring weren’t strong enough). I then replaced them with the old extruders and they’re working way better.

@Jeff_Keegan it was the same for me because the spring is not big enough. I added a small rectangular ABS sheet about 2 mm thick under the spring and it works great.

Hmm. Maybe it’s worth modifying the design to raise the mount at the bottom where the spring sits. …but I just got it working again. Note to self: do this when the constant jamming reminds you why you wanted to upgrade these in the first place.

Ok that didn’t take long. Switched BACK to the upgraded extruders, but printed SCH_Spring_Adj_rev1.stl from http://www.thingiverse.com/thing:62510 to use as a spacer to compress the springs a little more. We’ll see tomorrow if it worked well enough to make it through a large print (it’s been jamming with the old extruder due to any slight imperfections in the plastic).

@Jeff_Keegan Good luck! I am still fighting the Ninjaflex. I found out that curling is my problem. I am trying to adjust the temperatures to get over this. Keep us updated.