![]() Hi everyone, I hope you are all well, I just wanted to ask if you guys know what this material is? Why can’t I engrave such an effect with my 20w module? My laser machine is ZBAITU Z40. Before that, I tried to use stainless steel and titanium alloy plates, and also tried a variety of different engraving speeds. Can someone help? me? I can’t find any information about it on YouTube. .

Hi everyone, I hope you are all well, I just wanted to ask if you guys know what this material is? Why can’t I engrave such an effect with my 20w module? My laser machine is ZBAITU Z40. Before that, I tried to use stainless steel and titanium alloy plates, and also tried a variety of different engraving speeds. Can someone help? me? I can’t find any information about it on YouTube. .

zbaitu have been banned from this forum for spam, so it also wouldn’t surprise me if they have exaggerated the capabilities of the hardware they are selling, or not made clear how to achieve what they are advertising.

I have no direct knowledge here, but I know something about these colors of oxides from machining, so I’ll try to be helpful.

Typically titanium shows this effect more strongly than steel, and stainless steel resists oxidation (that’s the whole point of stainless!) so titanium is what you are looking for. The color is a function of heat, so I would expect you to need to use thin titanium to reach those temperatures momentarily. It looks to me like that’s quite expensive.

Good luck.

Looks too good to be true or else it would be all over the LightBurn forums and elsewhere.

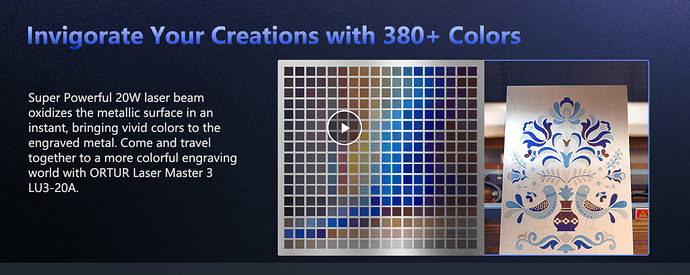

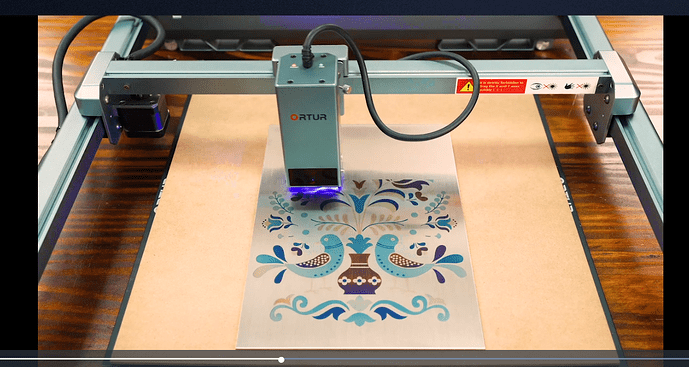

ZBAITU didn’t mention that they can achieve this effect on the product page, but I saw that ORTUR advertised that their modules can carve this effect, I think it’s also 20W why mine doesn’t work… I also tried over titanium … but its color is very dark and monotonous …

Your laser has to be capable of changing frequency and pulse width.

"Another important consideration for stain marking is the pulse frequency of the laser. Peak power of each focused laser pulse decreases as pulse frequency increases. Since the goal of stain marking is to heat the surface rather than vaporize it, lower peak powers and higher pulse frequencies tend to generate more heat on the surface of the part rather than engrave into it.

Some fiber laser units allow for the pulse width of the laser pulses to be changed.

By making the pulse width longer or shorter, one can control the amount of heat on the surface of the part. By making small changes in pulse frequency and pulse width, the thickness of the oxide layer in the stain mark can be varied and those discreet changes in the oxide thickness result in color differences in the eye of the viewer"

You are talking about a fiber laser machine… mine is a laser diode… it is different

Yes, but as far as I can tell you need a fiber laser to do the real color engraving like that picture shows. I’m pretty sure this is beyond the capability of a diode laser.

It’s possible that the Ortur has a more tightly focused beam with a Fast Axis Collimator (FAC) lens.

@easytarget wrote some really thoughtful comments on those laser heads:

So I could imagine that the very best diode laser heads with very thin Ti sheet could produce colored output. Given that this is oxidation, I could imagine air assist helping provide enough O2 rather than blowing away smoke for this use?

But the cost for those best diode lasers as a system starts to get close to the cost of the least expensive Fiber Lasers which I’d expect to do a much better job here.

I don’t think I’d have a lot of faith in anyone that tells me that 22 > 30, like the zbaitu store … their statement laser output power reaches 22W, which is 3-4 times higher than the 5W and 10W laser

Ortur states It couldn’t engrave or cut directly: Glossy metal plate, Transparent materials, Reflecting materials, Some materials in white color or pervious to light, etc. You need to use the marker pen to black it to engrave.

In the real world when you have to or want to do this… it’s not so easy… I have a 60W MOPA fiber laser and there really little out there that helps you ascertain what color for a specific setting…

Dog tag is thin, same values don’t work on anything that isn’t the same type/thickness of metal, this is a link for just stainless steel .

On the right is some scrap 1/2 steel, managed to get blue out of it… ![]()

I have a number of these that just disappear when the angle of the light changes… putting them somewhere they can show off is difficult. Did a mug, the image looks like it’s banded unless you roll the mug and the bands stay where they are…

That link doesn’t really address using a laser, since it leaves out thermal conductivity. Meaning any change in speed will cause different surface temperatures to occur, within reason. With most natural material are close to insulators…

The different colors are for different oxidizing/annealing caused by the beams excitation. If you laser doesn’t create enough heat, you may never be able to reach that temperature, as the metal conducts it away very fast.

I would bet money they do not have the file to create that work available to anyone and I’d be surprised if it actually worked. I’d love to be surprised. Just ask them for it… they give values at one of their sites… one speed/power lines/mm but say nothing about multiple colors.

These low power dpssl visible light lasers aren’t really at a good point doing this… Most of the visible light is reflected, so you have to have lots of power to do a little, without involving the speed of conductivity sucking the heat away…

Fiber lasers are used for this, at least in a reasonable price range… Many of these are sold as fiber, but they are not.

Since this is a rather technical crowd here’s a disassembly video of a Enjoywood Fiber laser… I’ll add this, it’s an amazing video of a fiber created Kirigami Circuits…

Good luck

![]()

that was fun to watch and funny.

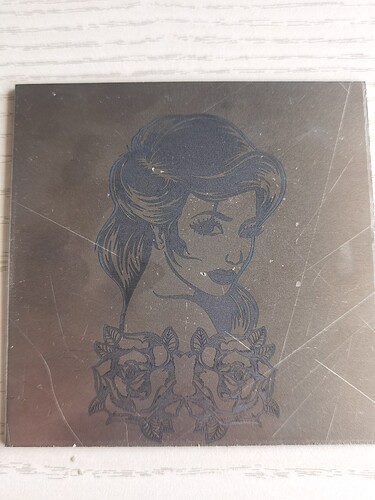

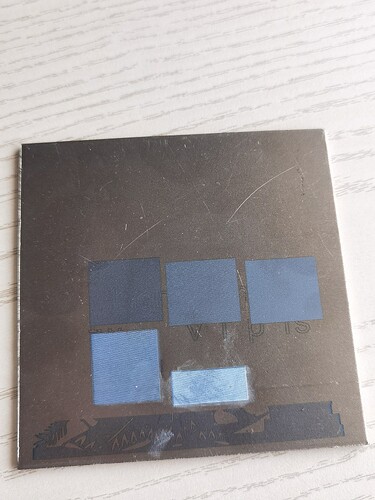

Laser metal color engraving is possible, but it won’t be very colorful.

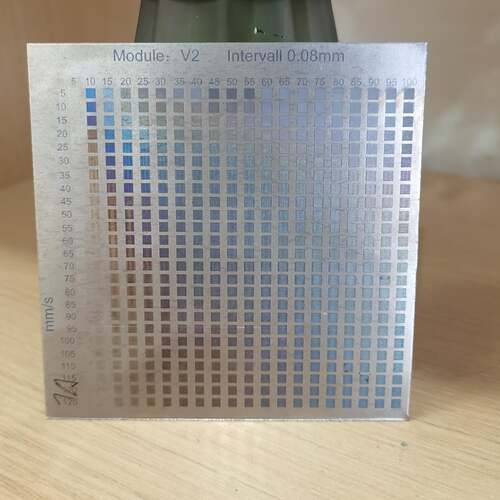

You can try testing with this Lightburn file.![]() LT-4LDS-V2 titanium color engraving file

LT-4LDS-V2 titanium color engraving file

For metal material, we suggest you choose matte material 0.2mm thickness or more. High power laser module for long time engraving too thin material may bend. If your laser module is not designed with reflective protection inside, prolonged engraving on glossy metal plate will directly damage the internal diode due to the refraction of light.(As long as the metal material that can reflect light, without reflective protection there is a probability of damage)

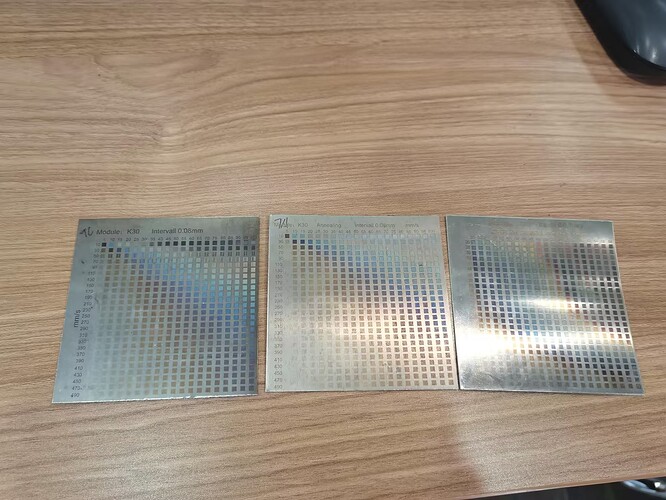

From left to right are pure titanium alloy,titanium , stainless steel. The optical power of the laser module is 30W, and the engraving machine is Ortur LM3. The color performance of pure titanium is better than stainless steel.

The image below is from one of our customers engraving on stainless steel.

Dude, thank you for the advice you gave me. I will purchase titanium alloy and stainless steel plates and try again. The file you shared with me cannot be imported into the software after I download it.