Someone wrote:

everyone but Easytarget should be aware of too many of the diode laser vendors exaggerating their specs.

Immediately after I wrote:

The manufacturers headline claims are outrageous, of course,

Once I’d finished giggling It got me thinking about lots of stuff, This response is tediously long, but I thank you at least, for getting me to think about this

Good , Fast , Cheap : Pick any two.

Personally I’m going for ‘good’ and ‘cheap’. Other people will choose differently, of course, depending on their skills and priorities.

Beam Equivalence:

If we assume the beam on the K40 to be 0.2mm diameter (this seem to be the normal assumed size) and the emitted power to be the full 40W then the energy density of the beam in watts/sq.mm is 40÷(π×(0.1^2)) = 1280.

Doing the same calculation for a 6W diode (*) with a 0.08mm beam gives 6÷(π×(0.04^2)) = 1200 W/sq.mm

Given these similar values I don’t think that claiming 40W beam intensity equivalence is particularly deceptive, and the so-called spec sheet they post seems pretty accurate regarding the electrical characteristics. As for the rest of the advert, yes they are exaggerating a lot, but so was the beer commercial I just saw (apparently it’s guaranteed to get me laid…) and the toothpaste advert before that (same promise). I can ignore it.

Some Practical experience with a 40W equivalent diode laser module:

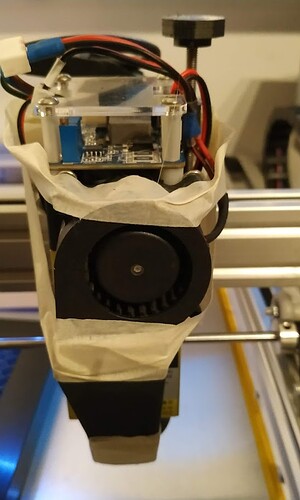

When I made the sign shown in the previous posting my ‘air assist’ looked like this:

(that’s a 40x20 radial fan and a simple cone nozzle, lots of masking tape, and pathetically low pressure / airflow)

The main engraving was done with 4 raster passes (X, Y then the 2 diagonals) at 35mm/s, using 80% power, 0.1mm pass width and fast travel in whitespace. It took just under an hr to run that as a single job, the results are shockingly detailed and good. The material is from the Rowmark Duets range.

It then took me ~40 passes at 30mm/s to cut the 3mm backplate from some spare marine ply, lowering 1mm every 10 passes, I guess that job took an hour or so of my time in total. I remember making several cups of tea in between passes, and deciding that I needed to get serious about the air assist

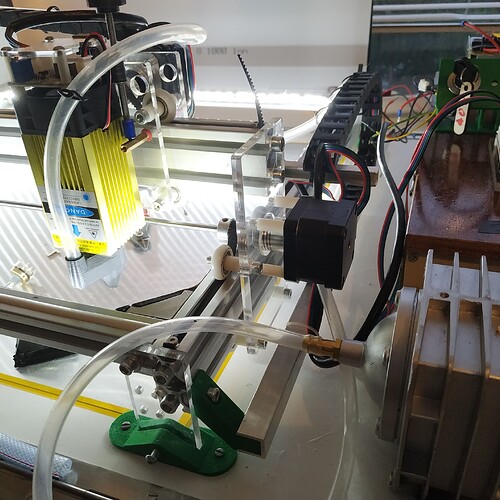

Move forward 2 months and I’ve been busy:

The pump is the largest I can afford, a bigger pump would be better.

The nozzle is on my own design and on my cults page here (free download)

With this set-up and focussed it cuts 2mm ply in 2 passes at 12.5mm/s. The only reason it needs 2 passes is so that the focus can be moved down for the second pass. The first pass does most of the heavy work, the second pass clears and separates the cut.

I haven’t really tried any other materials with this setup because my 2nd hand ATX PSU went south. A new PSU is being sourced.

Once it is running again I’ll endeavour to do some proper tests and post results in a new thread here.

In the meantime I hope that some of the info above is useful to people stumbling across this thread.

(*) I believe there is a 6W diode in my unit; it draws 0.14A when powered up with beam off (mostly the fan), and draws 1.32A when the beam is full on. Supply is 12V so that’s approx 14W of additional power being consumed for the laser. I’m happy to assume that half of that is getting lost in the driver. So a 6W diode seems like a good assumption, with an option on 7W.

The beam is actually perfectly square (not oblong, like the 5W module it replaced), I didn’t try to account for this in the maths above.

(**) IR lasers cut the translucent glue in cheap plywood much better than blue light ones do. If all you want to do is cut plywood boxes, cuckoo clocks and marble machines than this might be a killer argument.

Edit: image size and unnesscary paragraph