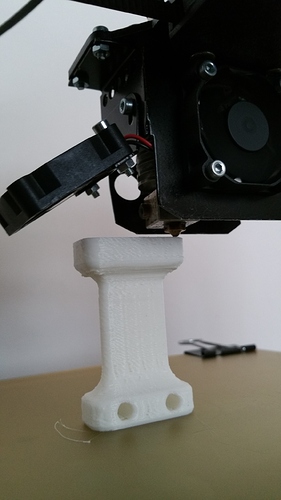

Hi i have problems with overhangs,how to solve this issue i print with pla 200c with max fans on 0.30 layer and try set extrusion and speed at low as possible any help or tip please

You can typically go much lower temp with PLA. Try decreasing in 5 deg increments.

Add a “blower” fan (centrifugal fan) with a duct.

I am wondering if this helps-as I’ve done casting, moulding and carving with ceramics and glass. If you print the object at another plane ‘longways’ horizontally’ by a 90° shift will that help? It means a longer ‘travel’ that ‘vertical’ doesn’t do (I guess) but keep at it!? there will WILL be a solution. The original automobile was crude when it started too-still is (to me) but it’s come a long way from Daimler-Benz/model-T Ford to now. 3-DP will too. I’m hoping to get into 3-DP soon (properly) so I read anything about it with great respect. Hope something in this rotation idea helps. I saw lowering temp idea-that seems really logical and a blower idea can reducing ambient temp. Help. So that the ‘substrate’ sets faster, like put the whole printer in a mini fridge-it may sound silly but would set the form quickly, of course it may become ‘brittle’ (my guess). Molten Glass does the same but it’s made use of ‘Artistically’. It’s called ‘slumped’ glass. But 3-DP you want technische accuracy no rough undercuts. Or Print from top down? starting with a base plate or will gravity 'stretch object?" Just ‘guess’n so’ Hope this (morsel) helps. Good luck guys! Fantastic work efforts! Accomodation on Mars I hope will be Printed using same process-sent ahead, built autonomously then Humans land Six months later courtesy of auto build-smooth transition… Just a thought! But I don’t know who’ll bring the beer-not me! Lol😊 see ya!

Thanks for all sugestions i will try them

no sweat! As I said-hope it helps! I’d be happy when it does! It will all happen… Look at where you are NOW! Think back ten years… someone’s said “impossible” yeah yeah ‘boring’ look at what YOURE DOING now! Excellent so cheers! Save your time put it towards what you’re doing-no need to write me-until a break through. And I’ve added you to a circle I made just now if that’s O.K.? so I’ll see what you’ve writ. Cheers!

no sweat! As I said-hope it helps! I’d be happy when it does! It will all happen… Look at where you are NOW! Think back ten years… someone’s said “impossible” yeah yeah ‘boring’ look at what YOURE DOING now! Excellent so cheers! Save your time put it towards what you’re doing-no need to write me-until a break through. And I’ve added you to a circle I made just now if that’s O.K.? so I’ll see what you’ve writ. Cheers!

You should try different layer heights. Somewhere around 50-70% of nozzle diameter usually works well. Too little or too much and you will get problems. Extrusion width probably has a similar effect. You would normally use 100-150% of nozzle diameter. And sometimes you should just use another slicer. Good luck!

Generally, a lower layer height will help with overhangs. Also check your fan speed and increase if possible.