@mcdanlj

Update on calibration experiment CURA vs Slic3r.

Summary of results:

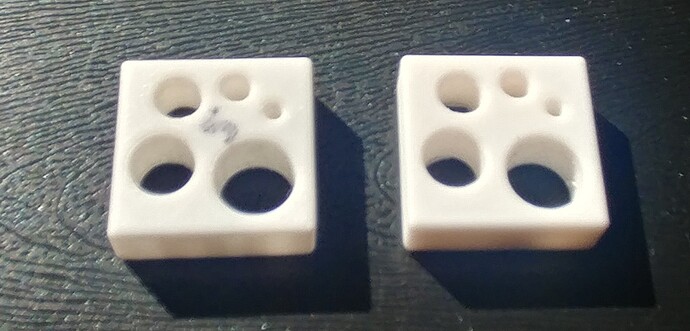

In order to tests the hypothesis that the diameter of holes in 3D printed parts are more accurate when the GCODE is generated using Cura, I 3D printed two calibrators. The only difference between them was the slicing software used to produce the GCODE (Cura, vs Slic3r).

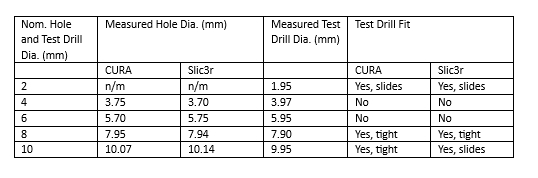

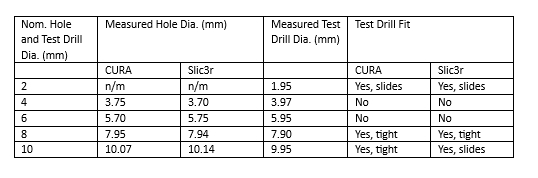

The X-Y accuracy of a rectangular printed part was slightly better when sliced with Cura, but the accuracy of the diameters of 2-10 mm holes was not appreciably different between the two slicers. The 2 and 10 mm holes were more accurately printed the 4, 6 and 8 mm holes were appreciably undersized . The latter result suggests that registration tolerances require a finer resolution than what my 3D printer fitted with a 0.4mm nozzle is producing with the current settings.

Detailed Description of Experiment and Results:

As an experiment I used FreeCAD to draw a 25 x 25 x 8 mm rectangular prism with 5 holes : 2, 4, 6, 8, and 10 mm (pictured), and exported the design to STL using FreeCAD’s inbuilt export facility.

I then used both Slic3r and CURA separately to produce separate GCODE files to print on a Tevo Tarantula Cartesian printer. The print and filament settings were the same in CURA as they were in Slic3r (see below). The Filament was used was the same in both prints (Tevor PLA+). The two parts were printed on the same day one after the other. In other words everything was the same between the two prints except the slicer used to produce the GCODE.

The dimensions on the printed parts was measured with Vernier callipers and the chuck end of a drill was used to check for fit in the holes in the calibrator thing.

Results

Part Nominal Dimensions 25 x 25 x 8 Result with Cura 24.95 x 25.05 x 8.18 Result with Slic3r 24.84 x 24.87 x 8.11 (Cura appears to be slightly better in XY accuracy)

The other results are summarised below:

Below I’ve copied what I feel are the most relevant printer and print settings.

bed_temperature = 75

bottom_infill_pattern = rectilinear

bottom_solid_layers = 4

cooling = 1

disable_fan_first_layers = 2

dont_support_bridges = 1

duplicate_distance = 6

end_filament_gcode = “; Filament-specific end gcode \n;END gcode for filament\n”

end_gcode = M104 S0 ; turn off temperature\nG28 X0 ; home X axis\nM84 ; disable motors\n

external_perimeter_extrusion_width = 0.4

external_perimeter_speed = 50%

external_perimeters_first = 0

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.4

fan_always_on = 1

fan_below_layer_time = 60

fan_percentage = 0

fill_angle = 45

fill_density = 10%

fill_gaps = 1

fill_pattern = rectilinear

first_layer_acceleration = 0

first_layer_bed_temperature = 75

first_layer_extrusion_width = 0.4

first_layer_height = 150%

first_layer_speed = 30

first_layer_temperature = 225

gap_fill_speed = 20

gcode_flavor = reprap

has_heatbed = 1

host_type = octoprint

infill_acceleration = 0

infill_every_layers = 1

infill_overlap = 55%

infill_speed = 60

layer_height = 0.1

max_fan_speed = 100

max_layer_height = 0.35

max_print_speed = 60

max_volumetric_speed = 0

min_fan_speed = 35

min_layer_height = 0.1

min_print_speed = 10

nozzle_diameter = 0.4

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0.4

perimeter_speed = 30

perimeters = 1

raft_layers = 0

regions_overlap = 0

resolution = 0

retract_before_travel = 2

retract_layer_change = 1

retract_length = 5

retract_length_toolchange = 10

retract_lift = 0

retract_lift_above = 0

retract_lift_below = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

seam_position = aligned

skirts = 0

slowdown_below_layer_time = 5

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.4

solid_infill_speed = 30

spiral_vase = 0

support_material = 0

temperature = 210

thin_walls = 1

threads = 4

top_infill_extrusion_width = 0.4

top_infill_pattern = rectilinear

top_solid_infill_speed = 30

top_solid_layers = 4

travel_speed = 40

![]()

![]()