It’s wired up and moving. I’ve set it so that the inductive sensor is probing to tram the bed over the pivot points, which I think is the intent. I moved the bed forward for more usable area, so I had to adjust the

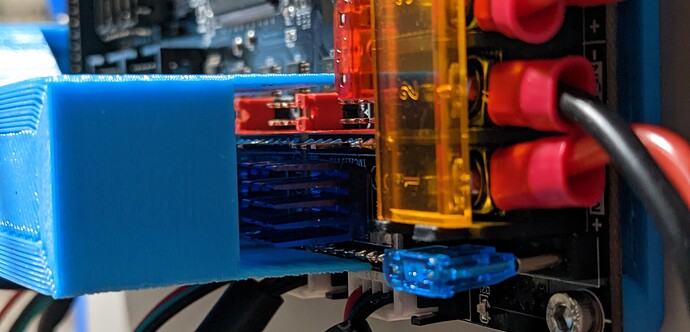

I’m able to set the stepper driver cooling fan speed; it’s controlled by PWM. It also runs only when the X, Y, or extruder steppers are powered, in the default config.

The stepper driver cooling fan shipped with the printer is certainly not silent. I could put a Noctua 4010 fan in place. It’s a 24V system, though, and Noctua makes 12V but not 24V fans — but I can just configure it for 50% duty cycle. (Klipper does have the ability to attach a temperature sensor to a fan, if I want to use it. But I think that if I switch to a noctua I won’t care.)

The resonance testing for klipper resonance compensation made it clear I need to add some cross-bracing to my printing table. I’ll expect to run that again after I add the cross-bracing. But also it’s a pain to try to hold the Raspberry Pi running the printer right next to the print head, because the accelerometer doesn’t like long wires, so I have ordered a Raspberry Pi Pico to connect to the accelerometer to make it easier.

The tiny little fan on the volcano hotend could be worse, but it’s not great. I can definitely feel the vibration, and that will show up in surface finish. I’ll probably see what I can do about putting something more like what I had on the cantilever printer eventually.

The 7.5mm/s probing speed SecKit provide in their default klipper config is way too fast for accurate probing on my system. I chose 2mm/s and got typical repeatability within 1 micron, whereas with 7.5mm/s I got about 25 microns of variance.

I feel uncertain about the bed mesh probing. It’s quite consistent from run to run, but the mesh it generates isn’t as flat as I had hoped for. Here are the raw points, probed with a cold bed:

0.027507, 0.160757, 0.247757, 0.290757, 0.274007, 0.175007, 0.029507

-0.036993, 0.071007, 0.144007, 0.169757, 0.128257, 0.038507, -0.113243

-0.115993, -0.009493, 0.061757, 0.095007, 0.048507, -0.050243, -0.197243

-0.177993, -0.064243, 0.019507, 0.049757, 0.011757, -0.067493, -0.195493

-0.198493, -0.072743, 0.004007, 0.041257, 0.024757, -0.059993, -0.159993

-0.214243, -0.091743, -0.014243, 0.029507, 0.021507, -0.050743, -0.157993

-0.261993, -0.145743, -0.042493, 0.011507, 0.018507, -0.044993, -0.156743

That’s .55275mm different between lowest and highest point, after tramming. The tramming happens near points measured at 0.027507, 0.029507, and 0.011507 so the tramming was done right, the bed just isn’t as flat as I would have hoped. It’s not as flat as the bed on the corexy I made myself.

The corexy I designed myself has a 6.35mm thick 330mm x 330mm bed with a 300mm x 300mm 750W heater. This has an 8mm thick 350mm x 350mm bed with a 330mm x 330mm 400W heater.