Considerations of course are voltage (110V NA, 220V EU, 220V at 30 or 50 amps) diameter/mounting system, and budget.

(ob. discl., I work for Carbide 3D which makes and imports a couple of options)

Inexpensive options seem to all be based on the Makita RT0701(NA) and RT0700(EU) with a new European-saftety-standards mandated option, the RT0702 which adds a “No auto restart” feature (which interferes w/ using it in a CNC w/ a relay) — note that those are 65mm in diameter) or other trim routers such as the DeWalt DWP611 and D26200 (69mm) or Bosch Colt PR20 (though that fell out of favour Precision Bosch-Colt Collet Kits (precisebits.com)). There are various collet systems, with ER-11 being offered on variants of some where the originals had a proprietary system. Note that comparing these to others is difficult since their rating seems to be given as their peak draw.

There are myriad VFD spindles, which are divided by diameter (65 and 80mm), Wattage (300, 800, 1.5KW, and 2.2KW) and collet system, usually ER, sized from ER-11, through ER-16, up to ER-20, though there are systems which will support an ATC.

Bridging the gap in-between are “milling motors” such as are offered by AMB/Kress, Mafell, and Sauter — usually from 800 to 1,000 Watts. These usually have a proprietary collet system, though sometimes there are adapters to other industry-standard collet systems such as ER-16, ATC is an option, and some units will have a “quick-change” mechanism where a lever will open up an 8mm diameter tool holder (note that rather than collets, such systems use reducing sleeves for other diameters) for changing tools.

Ages ago, there were other options/ideas, but they all seem to have dropped out (glad to have seen the last of the Dremel/rotary tools) — one which was striking was a motor which used a series of brass reducing pulleys for torque.

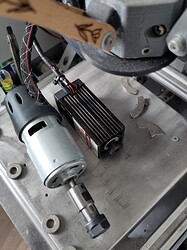

As certain forums joke, “This thread is worthless without pics!”, so here’s my Mafell FM 1000 WS which I finally got around to mounting on my Shapeoko 5 Pro: