Hi guys, I’ve recently bought a second hand K40 and have had tons of fun learning how to use it over the last few weeks.

I started to engrave a piece of ply on Friday and the laser stopped firing half way through, I then realised my water pump wasn’t on. Yes I know, BIG mistake.

I thought I had blown the tube after reading comments on several forums, so I ordered a new replacement. I fitted the new tube this morning and it wont fire.

I’ve checked all the wiring and switches, they seem fine.

The question is, is it possible that I have destroyed the power supply as well?

- The only thing that you replaced is the laser tube?

- Did you reconnect the cathode all the way back to the LPS?

- Did you mess with any of the wirings, especially to the LPS.

- What does the laser power meter do when you run a job???

[please reference your answers using the #]

You could have toasted the LPS but we can check some things first.

Please post pictures of:

- Your control panel

- The connectors on your LPS

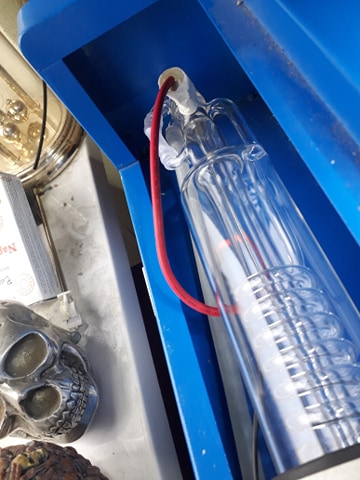

- The laser tube compartment showing both anode and cathode connections

Thanks for the quick reply.

#1 I only replaced the tube.

#2 I used the existing wire.

#3 Just checked to see if there were any loose connections.

#4 Power meter does not move when running a job.

Sorry, it will only let me upload one at a time.

- With power on, are any of the led lights down on the LPS lit? If so which ones are lit?

As far as I can see, there is only one LED, next to the test switch, it is lit when power on.

Make your machine and eyes safe [covers closed and eye protection on] then push the test button on the LPS and see if it fires?

I’ve already tried that, absolutely nothing, no sounds, no movement.

Since the LPS power light is on and the test button on the supply does not fire the laser it is likely that the supply is bad somehow.

Sounds like a replacement is necessary.

Note: the installation of water flow and temperature protection upgrades would have prevented this failure. Also if you do not have them interlocks are also a necessary safety precaution.

If you want to investigate further into the supply you can do this.

The supply can sometimes be repaired but you must be a skilled in electronics repair.

DANGER DANGER the internals of the LPS creates lethal voltages.

You undertake the following at your own risk.

Follow each step below in the order provided.

- Unplug the machine from the wall

- Wait for 1/2 hr for the LPS HV to bleed down.

- Unplug the input connectors to the LPS

- Unscrew the LPS from the floor of the machine

- Remove the LPS cover

- Inspect the PCB for damaged components

Take & post pictures of any visibly damaged area.

Yes, the additional safety features are on my shopping list, this has been a very expensive mistake.

I am planning on taking the LPS out and giving it a look over, well aware of the dangers, I’m an electrician and have been an electronics hobbyist since a child.

Thank you for your time, it’s very much appreciated.

Ok when you get it open and see anything fried let us know.

Here is a great place to start

Been a busy day. You are obviously a human, but the robot didn’t know that and make it possible for you to post more pictures. The humans took over the robot’s job and now you can post more pictures per post! Blame the spammers for making everything terrible, sorry about that. ![]()

Update:

The new power supply arrived this morning, I’ve installed it and the machine is alive again.

Thanks for you help and guidance guys.

Excellent…

Did you see anything wrong inside the dead supply???

I’ve had a look and can see no damaged components or tracks, will have a closer look when I have the time.

There are power mosfets underneath the board that are likely suspects as are the power diodes.