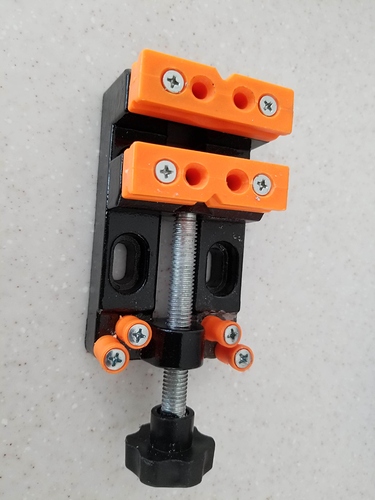

I was in need of a small vice for my dremel drill press and found this one on Amazon. It looked interesting so of course I purchased it. I was very surprised and impressed when it came. I did not make the connection that the soft jaws actually attached to the top of the vice and not the jaws themselves. I then realized that I can 3D print custom jaws. I then also realized that the spool shaped pieces are to hold round objects. Another 3D printable shape change for odd shaped objects. It is really a great tool for multiple jobs. The vice is light duty so not for the standard drill press but for what I need it for and the versatility and possibilities it possesses it is a great value!

Cool, I’ve actually been considering buying one of these for my dremel drill press.

Looked on thingiverse and found a couple of 3D prints for this vise.

Thanks I was getting low on tool drugs… this one went into the cart!

Just saw this:

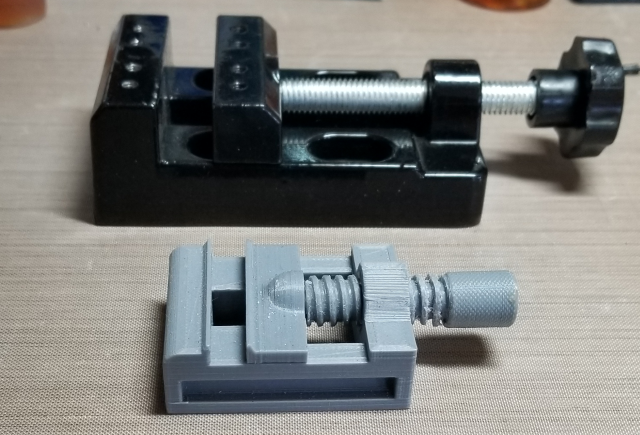

I did print out a small vice I found on Thingiverse but it did not work for what I was needing.

I pulled the trigger and ordered mine.

Awe, look that tiny cute vice

so did I …

Received mine today. Not bad, but as you would expect for a low price item it needed some tweaking.

The movable jaw was binding a lot as if got close to being fully closed. Seemed to be some excess paint underneath. Just sanded down with some sandpaper and a small block of wood. The movable jaw has some side-to-side play so you have to guide the jaw with your fingers a bit to keep it from twisting too much and binding.

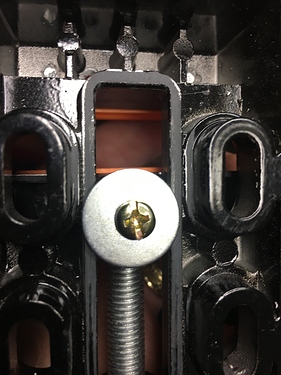

Tried attaching the flat pads and found that the screws on the movable jaw won’t quite go in all the way. Seems that the thread tapping didn’t go all the way to the bottom of the hole on both sides.

I didn’t have the right size tap so I carefully drilled out the bottom of the holes from underneath with a drill bit slightly bigger than the screw. This fixed the issue.

Looks like with the right screws / washers I could probably get this to bolt down to my dremel workstation if needed.

Overall I’m happy with the purchase

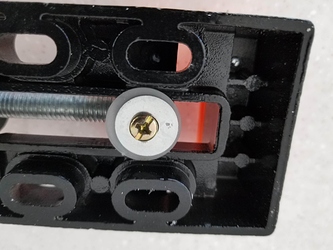

Added a single wrap of Teflon tape to the slide on the movable jaw and that took out most of the side to side play. Moves without binding now.

Also trued up the faces of the plastic jaws with some sandpaper on a flat piece of glass.

I got my vice and also tweaked it.

Mine didn’t slide smoothly until I replaced one washer with a nylon one.

The play in the slide on mine was “ok”.

I added some tap oil to the threaded shaft as they were a bit rough.

I knew I would lose the other jaws so I stored them on the base.

Cool, great ideas / tweaks.

I feel very lucky about my vise. It did not need any thing to make it work. It is interesting how much difference there can be between items.

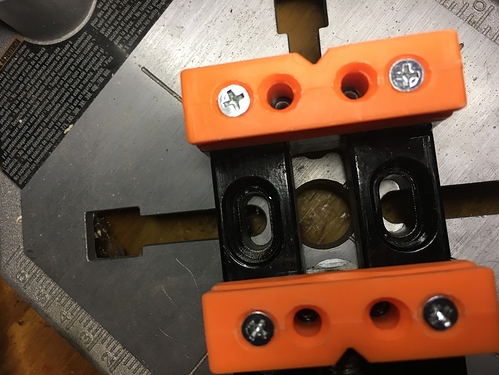

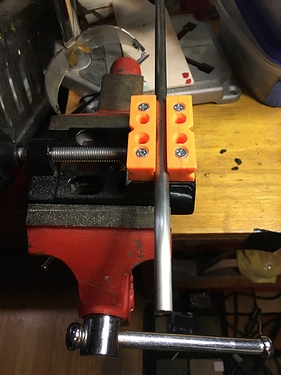

Using the big vice to hold the small vice to hold the small diameter metal rod while I cut it.

Work really well. The pipe holder below the jaws in my big vice was too big to hold this small rod.

Sweet! Nice solution.

Mmm a recursive vise!

…that good addvise