So, I just bought a K40 yesterday and found this forum this morning. Yay! Lots of peeps here from the old G+, which is nice.

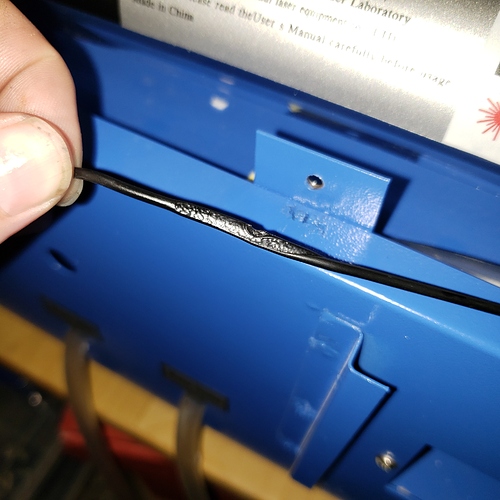

Laser isn’t here yet, but planning upgrades.

I need to get this thing up as quickly as possible so I can get some engraving done, but I’m willing to put some work in to make it better right away if the upgrades are worth it.

I know I’ll have to do the basic setup of the machine - does replacing the mirrors, lenses, mounts and head make sense at this point? If I have to calibrate everything anyway maybe I should just bite the bullet and replace all the stock stuff? If so, should I just get the air assist kit from k40laser.se? Looking at this lens and these mirrors from amazon.

Replace the pump seems to be the default option. Maybe with this one? I have a radiator and fans to add to the cooling loop as well.

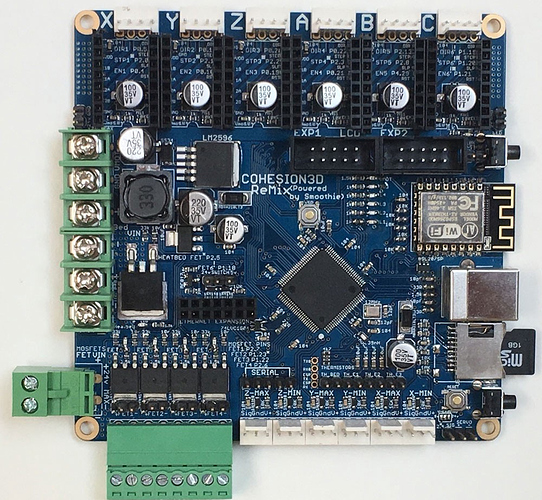

I have a cohesion Remix board I got from @raykholo years ago lying around waiting for something to do - should I go for it and rewire the whole thing or leave this for another day?

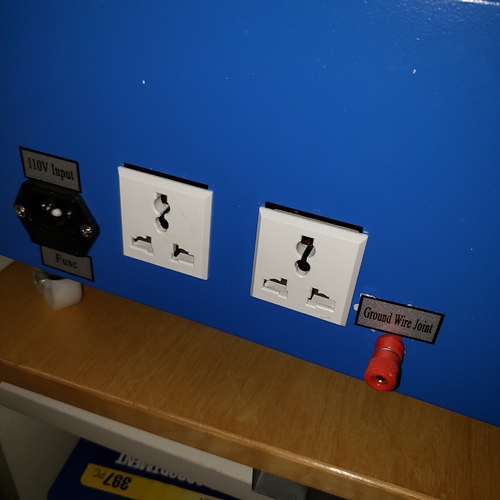

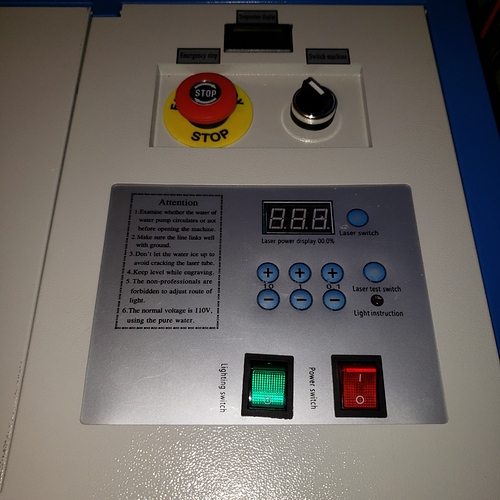

Interlocks - I like my eyeballs, but I’ve gotten some laser glasses from McMaster coming. Can I skip the interlocks for now and get to them later?

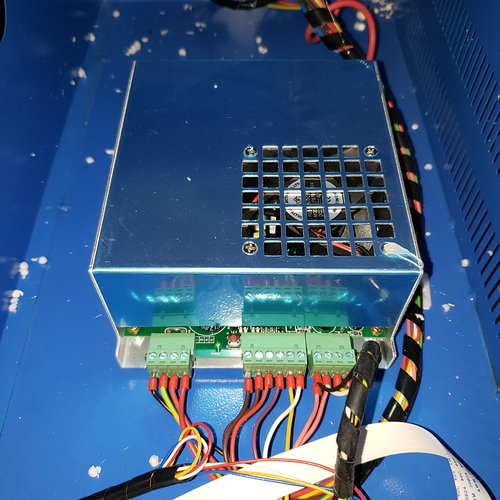

PSU?

Steppers? Gantry? Mechanicals? Adjustable bed?

I’m not trying to do anything fancy, just engrave anodized aluminum parts I’ve made instead of 3D engraving them with an engraving bit.

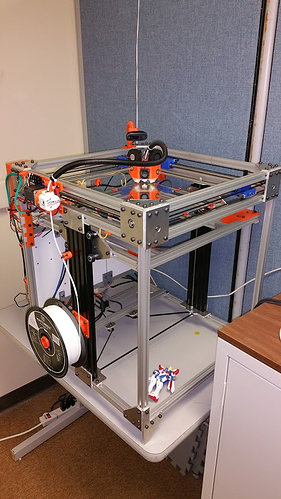

About me: I was a long-time member of the G+ herculien and 3d printing communities. Also spent a lot of time on the shapeoko forums. I’ve designed and built 3D printers and CNC routers.

Comfy with CAD/CAM/GCODE.

Now I build electric skateboards for fun.

Thanks in advance for your sage wisdom!

Matt