There is no cheap way to measure your tubes output…

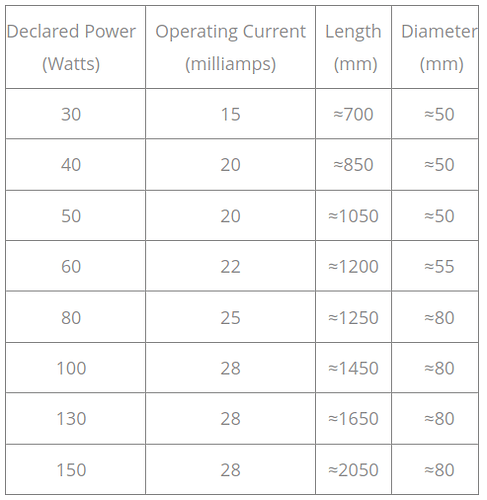

Measure the tubes length and use this table to determine what the output and current limits should be. The Chinese seem to enhance these values.

I bought a OMTech 50W… the tube was 880mm in length and measured 43W, which fits well with the tables value. The distance between the mirrors is where the light amplification occurs and where the power is generated. We generally just measure the overall tube length.

I have both a Mahoney meter and a doHICky from Russ Sadler.

Russ has a good video on measuring output wattage … worth watching overall. At about 10:52 minutes in, he starts talking about his lower cost doHICky.

The Mahoney is a commercial meter.

The doHICky requires a comparator and a bit of hardware. Russ sells the bit of hardware and the comparator is available from most of the large outlets… This is the one I have from Amazon, so you can find a suitable one.

Sorry I don’t have his current price for these or if he’s even got them available anymore. If you are interested let me know and I’ll pm you his email so you can easily ask him.

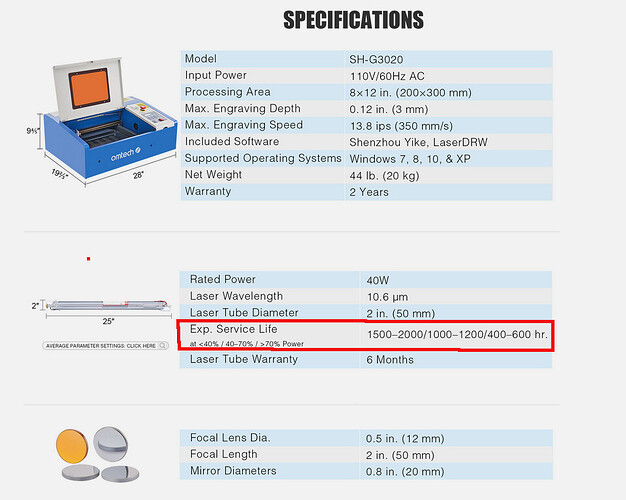

A glass tube will draw as much current as the laser power supply (lps) will supply … that’s the purpose of the IN terminal on an lps.

If your K40 has a pot or current control on the console, it’s manually adjusting the IN voltage so ignore the following as it will lase at the pot setting anytime it lases.

Generally speaking don’t test your tube at 100%, it’s much wiser when setting up new hardware to set it for 50% and double the results. If you lase it at 50% power then there is leeway to avoid too much current. If it measures 8mA at 50% then it’ll be 16mA at 100% supplied by the lps.

If you have a console mounted current control, then the mA meter will read the percentage of power… If you read 3mA@20% power, the rms current read will be 1/5th the actual current … 3mA@20% power has to have 15mA running through it 20% of the time to have a reading of 3mA.

If you have questions, sing out…

Good luck … have fun