I got to spend some time with my MoBeam (VG-7X) yesterday.

Here are the results in a nutshell with links to more detail:

Completed focussing using my USB camera. Indeed the focus is 30mm NOT 30cm ![]() . The dot ended up more round than I expected. Will measure DOF next.

. The dot ended up more round than I expected. Will measure DOF next.

I had to cut the mounting slide I made nearly in 1/2 to accommodate adjusting the lens. Thinking of a simpler mounting now that I know the FL.

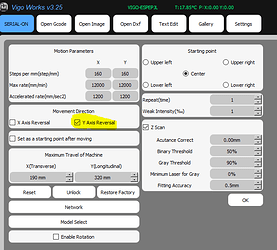

There was a software update. The VigoWorks app updated ok [its an .exe] but the firmware will not. Uggh! no place to go to get release notes or get help! I wonder if they fixed the proprietary Grbl problem in this release and connection to lightburn. I may never know.

VigoWorks seemed to work OK [except firmware upload] but it’s pretty rudimentary, single-threaded, and accompanied by poor documentation for the operational settings.

Laser temperature is displayed in the app, reminding me that if I change controllers I will have to account for diode thermal shutdown. There is a thermal signal on the interface which I think is an analog value.

The carriage X &Y were reversed, doh! cables were backward. Both X & Y moved 1/2 the expected distance. Doubled the step settings and it now works correctly. The default settings were loaded by VigoWorks based on selecting this model unit. Seems the default settings for this model are wrong in VigoWorks.

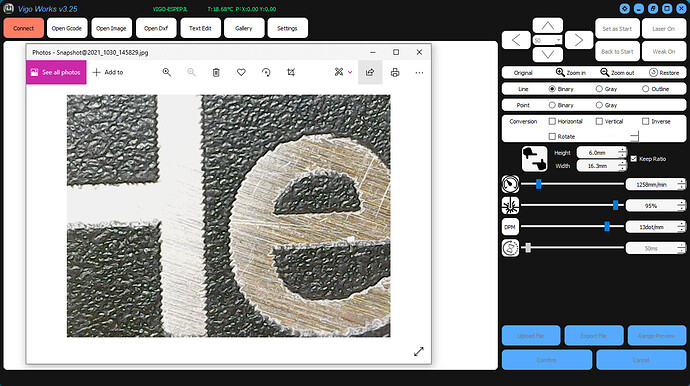

Text imaging worked surprisingly well on the first try. I was kinda impressed with the power. The USB microscope was valuable for looking closely at the results. Engraving on wood looked good. Engraving on coated plastic and metal showed scan line perturbations. Not sure of the source for this error some look like positioning errors others could be from poor overlap from incorrect image settings etc. I checked the carriage’s mechanical stability and slowed down the job but the error did not change.

Acrylic painted coated with flat black on front white on back:

Scans look like they start offset.

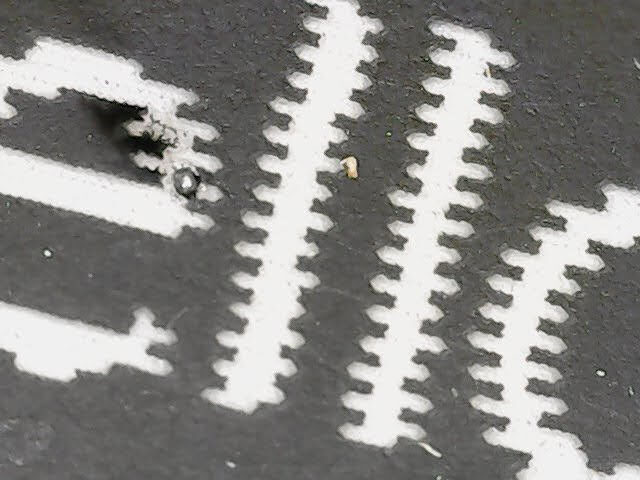

Metal (steel) painted with flat black. Post cleaning with soap and water.

Clear banding but scans look alternately short/long and not fully ablated.

Google research revealed that others that are engraving coated surfaces are running much higher power than I was.

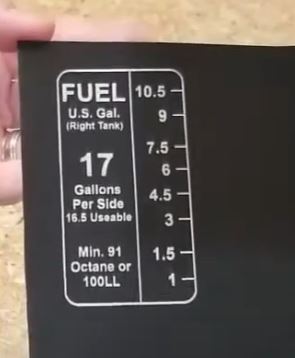

Clipped from a YouTube video running on the same machine + painted Al. The image seems to be crisper. Engraved near full power and slightly different dot settings than my run.

I like the simplicity of this machine. In general, it performed better than I expected. I want to use this to make labels for my RV and engrave areas of wood projects. At first attempt, I think this will be a good mobile shop tool when I get its settings, control, and safety to be rational.