Well, the bench bracket for the nibbler caught my eye and I bought one.

Nice, it did not fit a single drill in my shop.

That’s was when I went down a rabbit hole…

I snagged a motor off the parts shelf and figured it was simple enough to mount it on the nibber frame.

After fabbing 2 useless motor mounting brackets, a sheared-off coupler, and 3 days of frustration I ended up with a benchtop nibbler.

This is one of those projects that the worse it got… the more you wondered how you got here.

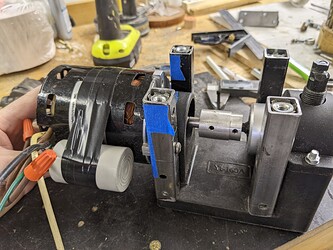

The final motor/cutter configuration. The first version had a flexible coupler to account for motor misalignment. When the cutting head jammed it destroyed the coupler so I made a solid one and got the motor closely aligned on center.

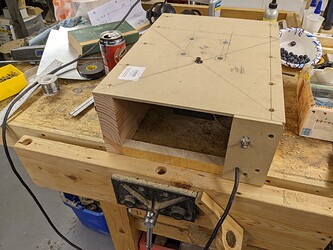

The benchtop nibbler. It is held in place with the bench vise.

The cutter/motor assy mounting from below. It hangs from the deck. Getting the head at the right depth to the table required ultraprecision fabrication!

The motor, I wish it was slower but that is what I had in the bin. Maybe connect it to a speed control later.

This coupler couldn’t take the jolt when the head jammed and self-destructed.

Made a solid coupler and redid the motor mounting so it was on center with the cutter. I may still find and add a stronger flexible coupler.

OUCH!

Poorly taken (one-handed) demo video…

What I learned:

- The motor does not need to be this fast. The nibbler produces significant vibration. The set screws in the coupler kept coming loose and it’s noisy. It does cut fast!!!

- There are no surfaces on the purchased frame that are square with… well anything. That said it was probably worth the $16 to get the cutter mounted in a stable configuration.

- Getting the bottom of the cutter aligned with the top surface of the table was painstaking. I finally thickness sanded the entire tabletop until the bottom of the cutter was at the right depth.

- In the final configuration the nibbling head is a pain to remove if I wanted to use it outside the benchtop configuration. Perhaps I will buy another head.

Improvements:

- The shad from the nibbler gets everywhere and is painfully sharp, especially when they find the inside of your socks. Need to add a bin below the head to catch them.

- A lower speed and stout flexible coupler would reduce vibration.

- A variable speed would be nice.

- A fence to help with straight cuts…