Hello all,

My Makerfront printer has sort of died. I control it with a raspberry pi runing Octopi. When the Pi attempts to connect to the printer, it says “SD Init failed”. Interestingly, there is NO SD card or socket on the printer.

The Makerfront is a Prusa i3 clone from 2016. It has a laser-cut steel chassis, and it is a fairly large printer, with an 8" by 12" bed. The control board is an Arduino Mega 2650 plugged onto a RAMPS 1.4 card. Pretty standard for that time.

Here’s the complete dialog between the printer and the Octopi:

------------- snip --------------------

Changing monitoring state from “Offline” to “Opening serial connection”

Connecting to port /dev/ttyACM0, baudrate 250000

Changing monitoring state from “Opening serial connection” to “Connecting”

Connected to: Serial<id=0x6f433cf0, open=True>(port=‘/dev/ttyACM0’, baudrate=250000, bytesize=8, parity=‘N’, stopbits=1, timeout=10.0, xonxoff=False, rtscts=False, dsrdtr=False), starting monitor

Send: N0 M110 N0125

Recv: start

Recv: echo:Marlin 1.0.0

Recv: echo: Last Updated: Jul 20 2016 8-15-13 06:14:52 | Author: (MakerFront, i3PRO_XL)

Recv: Compiled: Jul 20 2016

Recv: echo: Free Memory: 4495 PlannerBufferBytes: 1232

Recv: echo:Using Default settings:

Recv: echo:Steps per unit:

Recv: echo: M92 X80.00 Y80.00 Z4000.00 E90.00

Recv: echo:Maximum feedrates (mm/s):

Recv: echo: M203 X250.00 Y250.00 Z1.50 E22.00

Recv: echo:Maximum Acceleration (mm/s2):

Recv: echo: M201 X750 Y750 Z5 E500

Recv: echo:Acceleration: S=acceleration, T=retract acceleration

Recv: echo: M204 S400.00 T400.00

Recv: echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum xY jerk (mm/s), Z=maximum Z jerk (mm/s)

Recv: echo: M205 S0.00 T0.00 B20000 X20.00 Z0.40 E5.00

Recv: echo:Home offset (mm):

Recv: echo: M206 X0.00 Y0.00 Z0.00

Recv: echo:PID settings:

Recv: echo: M301 P12.00 I1.20 D200.00

Recv: echo:SD init fail

No answer from the printer within the connection timeout, trying another hello

Send: N0 M110 N0125

Recv: ok

There was a timeout while trying to connect to the printer

Changing monitoring state from “Connecting” to “Offline”

Connection closed, closing down monitor

------------- endsnip ---------------

I have tried to connect to the printer with some other linux program “screen” or “minicom” - no

go. The baud rate is too nonstandard ( 250000 ).

Clearly, the printer mostly works. I am able to use a local controller ( plugged into the RAMPS board with ribbon cables ) to jog and home it.

What to do? I have set up to compile the Marlin firmware - have done a successful build on that. Marlin has come a long way since version 1.0.0. But there are a lot of options; I figure a few days of trying different things.

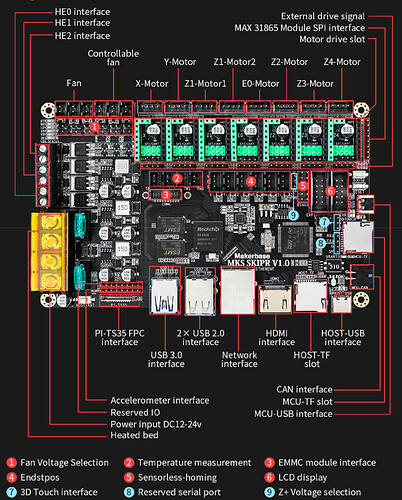

One can still buy an Arduino 2650 - genuine or clone. Also RAMPS 1.4 cards are out there. If OTOH I’m recompiling and replacing cards, maybe there are better cards now? 32-bit cards? Cards with tighter microstepping, quieter stepper action, auto-leveling?

There is no help from the company; they went out of business during the COVID, and their website now links to Chinese porn.