Ummmm…hmmm…that’s…not …good. ![]() My guess it’s because of that nick in the high voltage wire insulation. Soldering iron damage from when the wire was initially soldered on the tube maybe? I’ll let @donkjr comment on the best way to fix that.

My guess it’s because of that nick in the high voltage wire insulation. Soldering iron damage from when the wire was initially soldered on the tube maybe? I’ll let @donkjr comment on the best way to fix that.

is it just me or does the inside of that tube look really badly covered in bacteria and/or mold?

Yes I can see your point but I think its just the shadow from the back wall as the tube is really clean following the original questions raised about my not using algaecide.

No its not. I’ve had it fully working for a couple of weeks so it seems like an act of God for this to happen. I have a new LPS arriving today so I completely disconnected the machine last night so that the LPS would discharge but I suspect it is not the problem. I expect my next question is going to be when I find the same problem happens (and why would it not!!) then do I keep this new and better LPS or send it back? I have looked into new tubes and have come up with a possibility which gets a lot of good reviews on Amazon but I’ll cross that bridge when I get to it as the hope you seem to be suggesting is that it may be just a case of re-attaching the high voltage wire and I have reviewed @donkjr post about changing the tube.

Actually, if memory serves me right, the arcing could be caused by a bad LPS.

You definitely want working insulation, but also check all the wiring from the other end of the laser tube to the ground.

Ah, yes that’s what I was thinking about.

What Michael said relates to the fact that the tube is a component “in a circuit” which consists of:

The LPS as the power source, the wiring to the tube, the tube, the wiring from the tube back to the LPS. There could be an Amperage meter in the path from the tube back to the LPS. If anything opens the circuit after the tube, that high voltage will try to go somewhere else.

Hi, I am hoping this email gets to you as I am having problems getting logged in. I have tried replying to all the posts today but for some reason they do not appear as my malware is not happy with the site and I have logged a call with them. If this response does get to you then I will be getting my new LPS later today. Although I will check all the connections, the arcing is coming from the connection from the LPS to the tube so this connection is bad and I presume this might be either the connection to the tube or the tube itself. So, is it best first to try to reconnect the existing LPS to the tube or go straight to the new one?

Not always true, there MUST be a complete circuit and that means a path from the LPS all the way back to the LPS. Otherwise the current from the LPS will find the weakest point and arc from it. Have you ever heard that lightening seeks the easiest path to the ground? It is why we use metalic wires to direct electric flow in circuits…

Also, others have pointed out many times your wiring is damaged and until and unless you fix that you will not have a successful arc-less laser system.

Your points are fully taken onboard and I will check all connections in the circuit. So once I have checked them all should I then try to refit the connection from the current LPS to the tube or the new LPS to the tube as this is clearly the weakest point. Once I disconnect the high tension wire it may be clear what the problem and I have to do this anyway if I am going to fit the new LPS.

I would check and validate the connections to the laser tube coming from the LPS( red?) all the way back from the tube to the LPS(black). If a bad or poor connection is found and fixed, I would then repair the insulation on the red wire at the tube and try the existing LPS again.

BUT THAT INSULATION REPAIR MUST BE DONE AS A HIGH VOLTAGE INSULATION REPAIR. Not just wrapping some duct tape or electrical tape around it.

Ok will do. I have noted @donkjr blog on how to re-connect the laser connections and understand the requirement is that it is a high voltage repair. Once I disconnect I may be able to see if it is bad connection or a bad tube and I will post some pictures. Although I think the consensus of opinion is that my current LPS is probably unloaded, it is worth trying it first once I have re-fitted the connection. If that does not work I will know and I can then try the new LPS unless it is obvious the tube is bad. Many thanks to all for your assistance so far.

I am hoping by replying to the last message, this update will post as I still cannot login to the site.

Please find the results from connectivity checking:

I did find that there was a poor ground wire earth connection

<img width=“521” height=“442” style=“width:5.4305in;height:4.6041in” id=“Picture_x0020_9” src=“/uploads/default/original/3X/b/7/b760e2990d117df5a55788ff6358a3efbe7b95bb.png” alt="A hole in a blue surface

Description automatically generated">

So I scraped off the paint both sides and re-secured the ground wire earth to include 3 washers

<img width=“447” height=“511” style=“width:4.6597in;height:5.3263in” id=“Picture_x0020_8” src=“/uploads/default/original/3X/d/e/de5b9e933f97ff5314d1388990e21e8472cf0365.png” alt="A hole in a metal surface

Description automatically generated">

<img width=“437” height=“452” style=“width:4.5486in;height:4.7083in” id=“Picture_x0020_7” src=“/uploads/default/original/3X/5/6/56b65ed58d3b5899353b0fee199eedc4e5898cb9.png” alt="A hole in a blue wall

Description automatically generated">

<img width=“417” height=“360” style=“width:4.3402in;height:3.75in” id=“Picture_x0020_6” src=“/uploads/default/original/3X/a/c/acc714c0996838a0f4f16de722bd2002a26575c6.png” alt="A close-up of a blue box with wires

Description automatically generated">

<img width=“412” height=“455” style=“width:4.2916in;height:4.7361in” id=“Picture_x0020_5” src=“/uploads/default/original/3X/5/9/5930f71b9c8d0ce9bd6a3dafa4bb28d929f87a8c.png” alt="A metal bolt with a hole in the wall

Description automatically generated">

The cathode tube connection looked ok so did not remove the silicon tube

<img width=“391” height=“522” style=“width:4.0763in;height:5.4375in” id=“Picture_x0020_4” src=“/uploads/default/original/3X/3/b/3b5a6cf9a288dfcc58ff364263473d4391c7ebb5.png” alt="A close up of a glass object

Description automatically generated">

The anode connection looked ok and seems to connect inside the tube

<img width=“384” height=“512” style=“width:4.0in;height:5.3333in” id=“Picture_x0020_3” src=“/uploads/default/original/3X/2/2/220d93ab3a868a123cb394e6fffbfe6446f9affc.jpeg” alt="A close up of a device

Description automatically generated">

The wire was simply wrapped around the anode pin . No solder just silicon tube with silicon

<img width=“480” height=“640” style=“width:5.0in;height:6.6666in” id=“Picture_x0020_2” src=“/uploads/default/original/3X/b/f/bfd9291a470300e655314e90f7c4a90faa37ec68.png” alt="A close up of a wire

Description automatically generated">

There seems to be no damage to the pin and it does seem to connect inside the tube

These are the instructions I have taken from the site to re-wire the anode:

At the Anode end of the laser tube

· Remove the silicon sheath from the anode connection. Minimize forces on the anode pin. It should pull off but if not you may have to cut it off.

· Your anode wire may be twisted, screwed or soldered on the anode pin.

· Remove the old anode wire.

· Replace the anode wire in the same way it was connected, twist, solder or screw.

· If soldering use minimal heat. Some recommend using Teflon tape to hold wires that are twisted see video below.

· Route and restrain the wire in the same way. Usually tie wraps around the tube moving away from the anode end toward the cathode end.

· Flow silicon around the anode wire connection (use the white tube that came with your K40)

· Push the silicon tube over the wet silicon filling the tube. If you had to cut off the tube you will need to replace it with a piece of silicon tubing.

· Add more silicon to the top of the silicon tube if needed

Able to log back in again now that site is up. It seems my post last night did arrive apart from the photos as a I responded directly to the notification email. I can load them again if you wish to see them. The first test was to re-seat the anode wire and use the existing LPS and as expected this caused arcing so we know the current LPS is bad. I have now fitted the new LPS and connected to the anode so waiting for the silicon to set. In the morning I will conduct the test and I am keeping my fingers crosses that it works and that the tube is not bad as well.

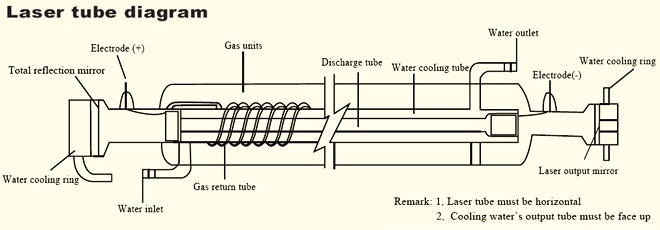

Just curious, is there water flow ONLY in the middle section of the tube? See diagram below:

Yes I believe so. Its hard to tell with it being clear but it looks no different to when it was working. I did do some changes to my water cooling and so had to re-bleed the system. Bubbles always form in the neck of the tube and are easily moved into my flow indicator which sits at the highest point in the circuit and by inverting this they then flow into the return bucket. I will be carrying out the test with the new LPS later this afternoon.

I am disappointed to confirm that I still have arcing from the anode with the new LPS. As I confirmed yesterday, I believe all other connections are good. If there is nothing more I can check should I presume that the tube is bad? If so, I have highlighted two from Amazon UK: The Cloudray is rated at 35-40W and the MCWlaser is rated 40-45W and both have good Amazon reviews. If the tube is considered bad, could it be the current LPS is actually ok or is it likely that if the tube failed first it would take out the LPS? Is there any other way of testing whether or not the LPS is bad or would you simply suggest changing both the LPS and tube together?

Having reflected overnight and in the absence of any further comments, I am going to do the following. I did intend to buy the MSWlaser because it offers a higher power rating and has ample good reviews but based on where I am I will buy the Cloudray for the following reasons and having read some excellent detailed Amazon reviews:

- It is probably equivalent in rating to my current tube, but the reviews suggest it works much better than the stock tube.

- It looks like a professional piece of kit.

- It should be compatible with the new Cloudray LPS.

- It has the cathode and anode connections fitted but the red cover is not a high-tension connector so I will order one to connect to the LPS so removing any possible connectivity issues.

- The dimensions (length and diameter) are slightly over the stock tube, so I need to be careful fitting to current mounts or buy new ones.

- My concerns are any damage on delivery, but reviews suggest it is well packed. I would not buy from anyone other than Amazon which has a good warranty and returns policy.

I am in the last chance saloon. If this does not work, I will be returning both items and will reflect on what to do next. I consider myself a practical person used to solving problems and I have had my share with 3D printing, CNC machining and diode laser engraving, so although I did expect issues hence my decision to buy second-hand and the fact that it did work well for around 2 weeks, I must admit that I am bitterly disappointed in the situation I find myself in so if you have any final comments or words of encouragement now is the time. It should arrive on Saturday so I will update after fitting. Many thanks for all your advice so far and I will see you on the other side.

Sorry that I entered this discussion late been on vaca again.

Usually, when the anode arcs it’s because the LPS is unloaded. I have seen arcs of 1-3 inches on an unloaded LPS. This usually means the tube is bad.

Most of the time in these situations the LPS is still good although arcing can damage the LPS.

Both the Laser tube and the LPS are consumable meaning they will both eventually fail. So you have not really wasted any $$ buying a supply it means you are ahead of the game with a spare supply.

There is no good way to test a bench supply other than to let it arch or to measure the output with a HV meter. I have found both methods to be unsafe, expensive, and sometimes inconclusive.

So hang on to the old supply as a backup it’s likely still good and you will be able to tell when you install it in the machine.