Help please,

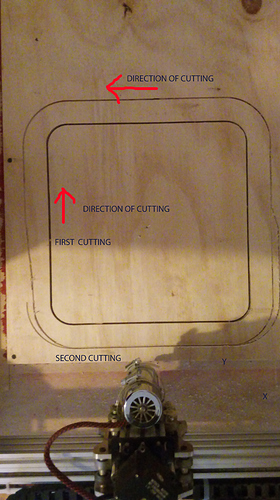

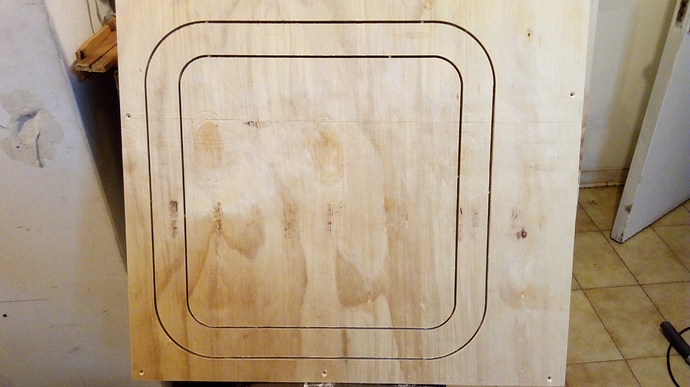

Hello friends, i just to want to ask for your help, i have a permanent problem with my ox machine, when I try to cut some design, the machine for a reason that escape my knowledge start to loose it´s course and loose it´s straightness, the interesting part of this, it´s in the same gcode file the machine cut perfectly the first part, but the second, start to loose it´s way. The funny thing, is that this problem exist since the beginning, I thought It might be a problem with the board, so I bought another, because I double check that nothing is loose in the mechanical part, I check the belt was tight enough, and check the squareness of the frame, everything seems ok. The first cut was perform cw and the second ccw. The feedrate was 800mm/min, the depth of cut was 1 mm, the spindle rpm was 10000. The material was plywood. i used a 2 flute end mill ,I really appreciate your experience and advice about this problem.

Cheers,

(suposition) one of your motor are in pain to keep power, check psu & driver voltage

Dude, you should cut both shapes clockwise. that’s the direction the bit wants to go. Always clockwise. (That’s been my understanding. I’m new to this though so others know more than me).

hello, thanks for your comments, im going to check the motor power nob, and test again the same file but this time cutting all the parts in clocwise, a soon as im done i upload the results. Cheers guys

I had a very similar problem. It turns out that I had a bad connection to one motor so it was being dragged which caused steps to be missed. To troubleshoot this, I needed to remove the belt so I could watch the motor turn with no other influences. Once I saw it didn’t move, it was obvious why it cut the way it did.

hello michael, in this case the wrong movement is in the x direction, so that´s mean that is just one motor is having issues regarding connection, im going to check every cable. you said that you had a same problem, it was in the x or y axe?, thanks a lot, cheers

@Felipe_de_la_jara Since the wrong movement is in the x-direction, it is most likely being cause by one of the y motors not moving in sync with the motor on the opposite side. Notice how straight your cut is when the y-motors are not moving? A y-motor inconsistency will cause one side to move further than the other until missed steps occur causing an effect of “walking” the entire gantry. Think of only one side moving up until there is so much tension that the other side finally releases and gets dragged along. That would definitely cause a skewed cut.

Based on my very recent troubleshooting, I would loosen the belts over both y motors, send a command and visually watch them to make sure they both react together. It will be obvious if they don’t.

ok, im going to loose both belts from the y axe and see what happens, thanks michael, i hope that solve my problem,i let you know as soon as i can. Cheers.

I’m going to suggest you check your wheels aren’t too right. The should be snug with some pressure, but not smashed into the extrusion.

All be sure your belts aren’t too tight. Run that same program with your z up high, and see where your problem is. I just had this issue, turned out one of my wires pulled out of the socket so it would do exactly what yours id’s doing @Felipe_de_la_jara

hello friends, i´ve spent this weekend trying to solve the problem that im still having with my machine, as just you recommended guys, first i loose the belt a little and this is what happening, the first cut was ok, but the second the machine wnet mad. the second thing that i did, was to remove the y and x belts, just to check the timming pulley, to my surprise, iv found that one of the y pulleys was loose, and the x pulley was complete loose, so i´ve tighten it both, i put back the belts and the next was…

Hurray! Next time you week be able to troubleshoot that problem yourself in a few minutes since you now know something about the machine!

finally¡¡¡¡¡¡¡¡¡¡¡¡¡ a perfect job with no problems at all, the machine just works perfectly and i was really very happy, until i remove the plywood to put another and start to make the same job, i reset the machine, and reload the file in chilipeppr, for my dissapointment, the machine start to make the same mistakes that did it before, this time in the first cut. as michael forte suggest, before to reassemble the belts i run the work to check if the motors are running, and yes, the motors were working just fine.

just want to say that it´s very frustrating to work with this machine, i´ve spent more time trying to make it work right than actually producing stuff. if there´s someone that may suggest another cause why my machine doesn´t work properly i would be very gratefull. cheers guys.

Ok, glanced through, didn’t see what controller your using. Tinyg? Are the stepper motors from open builds? Have you measured corner to corner to check for square? Double, I mean triple check your not having pullies http://slip.They can be very sneaky. If your stepper shafts don’t have a flat spot, use a hand file to make small flat spot for the screw to seat. Then make it tight. Add another set site off you have room to lock the first into place. If you tell the machine to 100mm in a direction and 100mm in y direction, does it move exactly that much? If your using tiny g, compare your settings to others that are know to work well. Acceleration would be the first thing to check.

Need more info if you want more answers!

Hello mark,

im using tiny g controller board V.8

i create the file with cambam

i use the chilipeppr interface

i check 3 times after the machine start to loose steps.

the motors are from smw3d, they have a flat surface in the shaft. now are very tight, they don´t move a bit.

the piece that was cut perfefct i measure it and was almost exactly to the dimensions that was design.

i measure the dimensions of the bed and is ok, have a half of mm difference. i dont know that´s is to much. could you tell me if there´s another interface that i could use instead of chilipeppr? just for testing?.

Thanks a lot.

You can also try Repetier/Pronterface for your testing but I doubt that’s the problem. Since you got the good cut, that pretty much tells you it’s a hardware, not software, problem.

I forgot to mention that in addition to seeing that one of my y-motors was out, the pulley had also worked it’s way to being very loose. That was a very important piece of information I left out and I see you had the same problem. That pulley must be solid with no play in it.

So here are the things to troubleshoot with hardware no that it’s been narrowed down:

-

Y-motors both work and turn in the same direction

-

The motors both start and stop at the same time, i.e., there’s no timing problems between them

-

The current to the motors is such that you are not missing steps. Search google to see how to verify stepper motor current is adequate.

-

The wheels on the track have enough friction across all of them that they aren’t too tight and aren’t so loose that they slip.

-

Your belts are nice and tight so there is no slippage.

If everything fails after this then I would try to reduce your cutting speeds and/or reduce the cut depth.

Hello Michael,

how can i verify that the timing between y motors are ok?

the same question regarding the current, maybe i just turn the the current nob to maximun to ensure that there is enough juice to move them?

the next weekend im going to check the connection between the motor to the board, im going to re solder all wires just to be sure that isn´t loosing steps because of that.

also im going to re check again the proper connection between the timmin pulley and the shaft of every motor, thighten up everything again and hope for the best.

thank you for taking time to help.

cheers.

@Michael_Forte I agree with all of what you stayed. Running and troubleshooting a machine can be very frustrating… But in the end you will be an expert. Keep checking connections. For me that always seems to be what the problem is. The fact that out is happening in different locations makes me think it’s not cutting speed or acceleration, but an intermittent connection, or loose wire to the board?