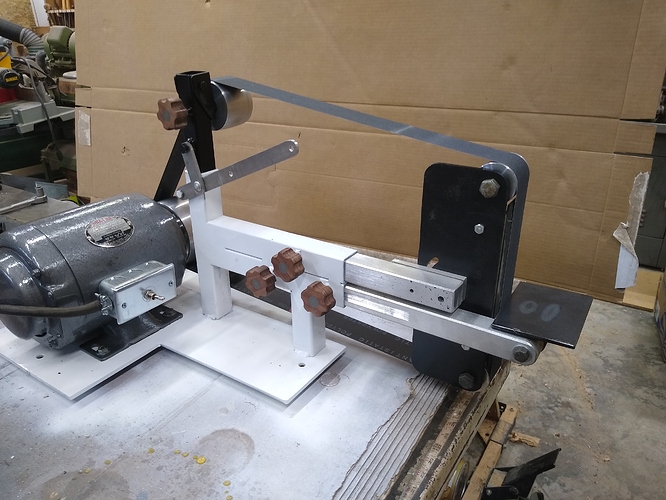

This is the finished grinder. Everything is working great. I sharpened my wife’s kitchen knives so she will be happy. Off the top of my head this is what it cost to make. Engine was free because I swapped out the motor for a treadmill motor, $130 for the wheels, $70 worth of belts to get me started, $20 and a trip to a metal fabricators scrap bin for the steel, $5 for a screen door spring to tension the belt, and $10 misc. electrical stuff. Call it $250

That looks nice!

Looks like you found solid bar for the arms instead of 1.5" hollow structural steel?

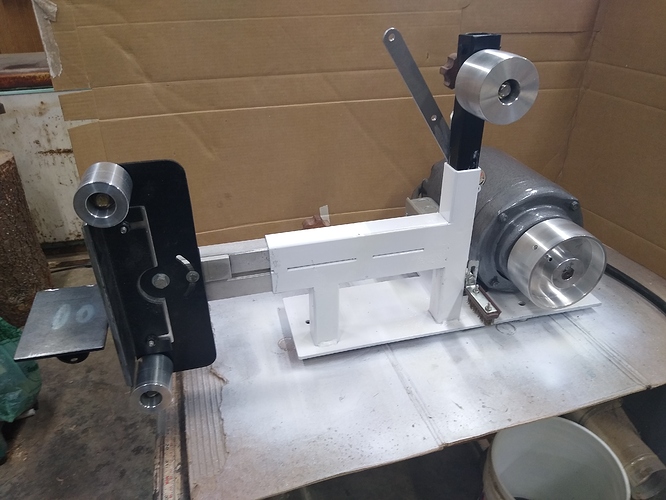

What I found in the scrap bin was 1.5" and 1.25" square tubing which works fine. I used the 1.25" tubing for the tensioner but for mounting the platen and the tool rest I wanted something that I could really tighten down and not worry about crushing. So I cut the arms out of some 1.25" alum plate that I had. I used my table saw making 0.25" cut each pass and then smoothed it on my 6x48 belt sander. The tool rest is mounted to a piece of 1.5" round tube plugged and tapped on one end. You can see the locking bolt at the end of the arm. It can rotate to any angle. I uploaded a picture of the other side where you can see the antistatic brush which is recommended. Apparently you can get a big shock if you are not careful. Static dissipation brush

I keep the humidity low in my shop and get shocked just by walking on anti-fatigue mat, even in the summer. The brush will be essential for sure. Thanks!

This is a really cool design. How did you decide on the depth: the spacing between the front and rear pulleys?

I have a carbon fiber bike and get repeatedly shocked if I walk it across carpet. It’s a lot easier to build a van de graaff generator than I thought, and sometimes it happens by accident.

I got the plans here: http://dcknives.blogspot.com/p/2-x-72-belt-grinder.html At the very bottom of the article is a link to the Bill of materials. This has all the information you need.