I’ve looked at the prices for acrylic sheet as case material for the Monocle and my heart shrank. If I’m paying that much for acrylic, I want to be shooting it with a laser to make something useful or beautiful. Heavy-duty aluminum sheet isn’t cheap either. But it needs to be encased to be safe, of course.

What can I do?

A CO2 laser won’t cut through aluminum even when it’s focused, at least at the power range that could possibly be installed in this machine. It won’t even cut through aluminum foil.

It turns out that aluminum flashing isn’t terribly expensive, and is widely available in a variety of widths. But (as @Eclsnowman pointed out ot me) alone it would oil-can and sound a terrible racket, as he discovered with 3d printers and 1/8" acrylic long ago.

That led me to think about Aluminum Composite Material (ACM), an aluminum/plastic/aluminum sandwich often used for making signs. It’s easy to cut, the aluminum would not burn from the laser, and it looks nice enough to use as a sign. But it turns out it’s not particularly cheap either.

So for a large-format laser, it starts to look like the box could cost more than the laser.

But you know what else is cheap? Masonite and contact cement are really not very expensive.

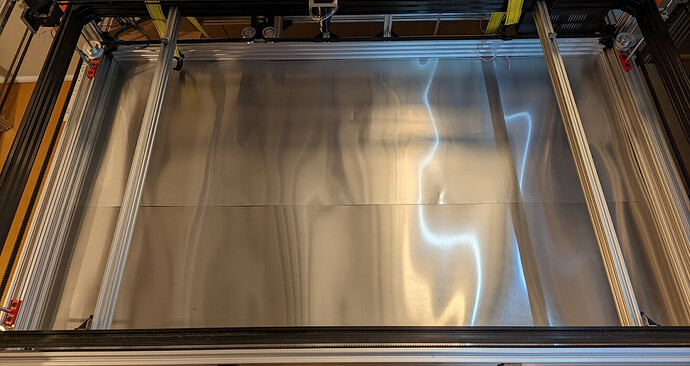

I could make my own “ACM” that’s an aluminum/masonite/aluminum composite sandwich, held together with contact cement. Masonite doesn’t burn that easily, and since it’s made of just wood I would expect that if were to catch fire somehow and be extinguished, it would probably (a) be easier to extinguish than the plastic in normal ACM and (b) be less likely to give off noxious fumes.

A 4’ x 8’ masonite panel is less than $10 in 1/8" nominal thickness; it’s available in 1/4" as well. A 20" x 50’ of aluminum flashing costs $43. 20" is 508mm, plenty for the largest likely useful depth for a Monocle, though you can get it 24" wide for $60 if you need over 600mm. $15 will get a quart of contact cement which is more than you’d need here anyway.

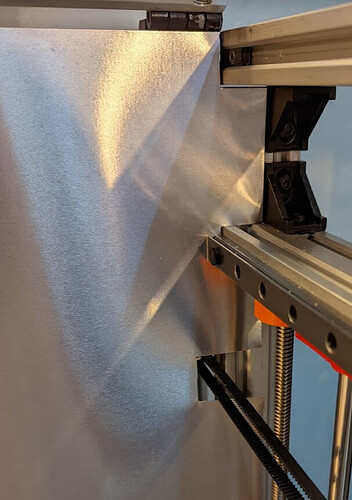

I would imagine cutting the masonite to size, gluing a very slightly undersized piece of aluminum to the inside face, and then gluing a ~4cm oversized piece centered on the outside face. Trim out the corners with shears, then fold it over and file the corners smooth. Glue those folded edges to the inside surface with more contact cement and clamp them in place.

It might even look nice. Brushed aluminum is classic, right?

Am I nuts?