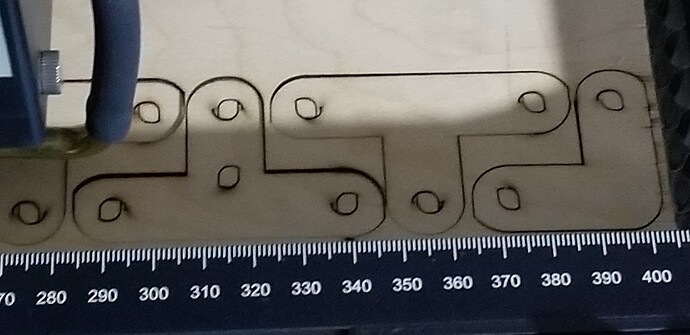

I’m under the impression that i need to tweak my Y axis rollers to fix this problem (it is on my Sculpfun S30 with the heavier diode vs my S9). The pieces I’m cutting are extra display connectors and the circles aren’t as necessary for this part of the process as they were for the main pieces. This is also to learn the differences between my laser cutters. There’s a massive difference in the amount of time it takes to cut out pieces, so I wanna fix this problem asap as it may also affect engraving. Picture is landscape to the X axis.

The instructions for building the machine tell me about a nut I need to loosen on the undercarriage of both sides of the Y axis until tilting the machine allows the gantry to slide from front to back effortlessly when the machine is tilted at a 45 degree angle from the front. I did that, but the speed that it moved at seemed kinda high. I wrote it off as the diode hardware being heavier because it is bigger, but this makes me wonder.

You mentioned that the diode hardware on the S30 is heavier due to its larger size. This could indeed affect the speed and performance of the machine, as it may require more power and time to move and cut compared to the S9.

Have you seen these?

Particularly:

If you increase the mass, you have to adjust for it in other places, like acceleration of that axes.

It looks like a mechanical issue to me. It might not be a single cause.

![]()

To be clear about it, the S30 is designed to handle the heavier diode hardware. The railing and such can handle the excess weight compared to the S9. My thought is that I likely torqued the guide wheels to S9 specs, since that’s what I had first… and the heavier hardware moving at similar speeds might need tighter torque specs, which I’m working on today (as soon as I finish this reply, actually). I plan to report back my findings asap. As I may be the first here to work with sculpfun machines, I know I won’t be the last. So hopefully this (and all my other) post(s) can be helpful to others in the future. ![]()

![]()

Possibly steps/revolution are off?

I’m with Jack here; this looks like slop in the X axis to me… In order:

- check belt tension

- check the X slider/carriage does not ‘wobble’ on the gantry

- check the Grub screw on the X motor belt pulley is not loose

- check the laser module is totally secure and does not wobble on it’s slider

- do you have a ‘fixed’ focus, or adjustable module. My module has a adjustable focus ring that is wobbly when screwed out. I packed the thread (ptfe tape) to stop this.

I’m wondering if this could possibly be the case, but I’m not sure. Thing is, I can jog the machine along the y axis from end to end and it inconsistently catches what I’m gonna call a “grind point”. This is a point where the machine moves much slower than it should and simultaneously makes a bit of a grinding noise. This only seems to happen when I move in 10mm increments or less. Sometimes its consistent for a moment, but then it changes to a different point on the Y axis. I’m sincerely not sure what to make of it…

Its definitely on the Y (front to back) axis. I have not experienced any sort of issues with it moving left to right. And the problem seems to.be inconsistent on the axis…so it’s very confusing…