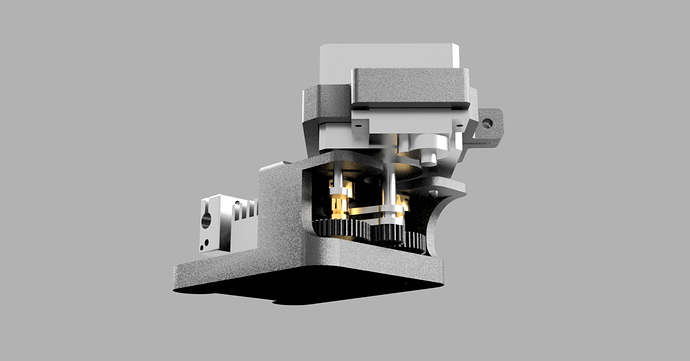

Working on a dual extruder for my printers currently. I´m basically trying to use one stepper switching between the two outputs. Short ways and direct drive should lead to less oozing. When switched the filament is completely released from the pressure. The difficult part is the tensioning, it is currently floating between the axles and gets engaged through the shift. Going to build a proto from that to see how well it works.

That looks interesting. I hope you can find a way to make it work. I made duals for chimera but that was two motors and you could save over 100g if you can do it with one.

I have built a prototype some years ago, have a look at https://www.thingiverse.com/thing:651723 Chimera Was released later, I always wanted to update to it, but I never found the time

https://www.thingiverse.com/thing:651723

@Jeff_DeMaagd Will see how it turns out. Maybe a classic version with two motors is more reliable. There is very little space for the tension system at the moment so I hope that part is going well.

@Benjamin_Deiss That looks nice, funny how there is always someone who did it first  There is also a version I saw that is shifting the tension with the drive in the middle. I wanted to have the gearing at least 2:1 and stay compact.

There is also a version I saw that is shifting the tension with the drive in the middle. I wanted to have the gearing at least 2:1 and stay compact.

Pad✌🏽: YelloWednesday aligns 3D Printing’s SolarPLexus

@Thomas_Herrmann I tried to avoid gears since they wether have to be big when printed or machined parts if small.