@Jorge_Robles The Floyd Steinberg algorythm is quite simple. See: http://blog.ivank.net/floyd-steinberg-dithering-in-javascript.html

@cprezzi can you do your test with your pot on max and limit it with the % 0-10 for example. be interested to see if you have a different response. i dont use a pot you see.

for reducing the min power. I dont think you will get it to go any lower as DC CO2 tubes have a minimal fire point with a minimal power. this is why you dont try and engrave much with a 100w tube.

Around 3ma is lowest our tube will fire.

About response time providing a trickle power fixes this. considering we can turn on and off the tube while dithering up to 600mm/s on a Chinese machine i think we can assume the response of the tube is not an issue.

The frequency of our PSUs PWM requires a signal greater or equally to 20KHz. currently i have left the period at 20.

Perhaps if we were trying to aim at trotect speeds 2500mm/s then the DC tube would be are hard limit. as RF tubes can respond much faster.

currently i really believe the fact we cant move at more than an average of 40mm/s without jittering is the problem.  its one hell of a dilemma.

its one hell of a dilemma.

@Bonne Wilce You are right. The bloody oversize of using gcode for raster ist the problem. We could reach at least 10 times the speed, if we had a correct raster command.

But there is also a physical effect. If I use a faster feed with more power, the engraving gets less dark, but deeper. That’s not what i want for a picture engrave. It just seems the wood needs some time to get dark.

In that case, you could do multiple passes, layer the colour.

I find different woods engrave better than some, poplar is crap  hardwoods can provide more colour.

hardwoods can provide more colour.

have a look at this https://msu.edu/~nk/laser/

No idea what its for, but its code looks like what i imagine we need

If you’re interested JS dithering, my code has a small bugfix compared to the link above: https://github.com/martinxyz/LasaurApp/blob/pulseraster/frontend/admin/rasterlib.service.js#L102 GUI demo (generates Lasersaur-specific gcodes): http://log2.ch/laser/pulseraster-static/admin/#/raster

@Bonne Wilce What sense does it make to speed up the feed, when I then have to do multiple pathes (and get deep cuts)? I prefer to go slower but darker in on path.

Unfortunatelly the link you provided is using Adobe Flash. That’s a no-go for me…

Because you can expose it multiple times without over heating perhaps. Just an idea.

Increasing the feed allows for lighter engraves that’s where you will get more of your grey scale. By the time you are cutting deep into the material it’s too much. Unless you want that 3d effect.

Drag a file into that link and look at the file it generates really interested to know what machine uses it and it’s results can’t seem to find any more info though.

Claudio Prezzi The image seems to shift in the laserweb raster about 2/3 of the way down. Do you know what causes this?

@cprezzi I think that now we are ending each others sentences. Both understanding the “dilemma” the same way, one I have been hunting for over a year. However I think some important practical aspects have been revealed in this thread.

Let me try and summarize my current understanding of the problem (applies to raster only) :

- The laser power cannot be adjusted low enough to keep from overexposing a raster image.

Therefore:

a. You can reduce the power by lowering software [power max] setting.

…Consequence: Reducing [power max] setting reduces the number of grey scale steps.

b. You can speed up the gantry (raster movement) to reduce the average exposure power while retaining the highest [max power] setting (100%) and therefore the grey scale range.

…Consequence: materials engrave deeper but less black with min power at higher surface speed and gantry speeds are limited by the controllers performance.

…

Potential Ideas for Solutions…

-

Fix something in the power control schema so that the laser power supply can be adjusted low enough to keep from overexposing.

a. This can be an effect of PWM-ing the internal PWM of the LPS. A dual control signal might fix this. Many other laser systems do such. -

Remove the relationship between [power min-max] and the grey scale granularity. Retain full grey scale granularity but factor the S value with a Scale power multiplier. i.e.

Sscale of 1 = grey scale from 100% - 10% = S values of S1- S.1

Sscale of .1 = grey scale 100% - 10% = S values of S.1- S.01

a.I don’t understand the grey scaling algorithm so this may be a useless idea. Its just that we know we can get low enough power by adjusting the max PWM so why does that change the grey scale granularity. @cprezzi -

Move to a dithering approach.

a. Dithering simplifies a lot of things at the laser. The beam is always turned on/of and the pot simply controls the contrast. This is how a stock K40 works.

…

Hope these long discussion are not annoying. I find them useful in synchronizing knowledge/learning and helping get to ideas for improvements.

Looking forward to the community adding to the “Potential Ideas for solutions”.

@cprezzi easy as pie: https://github.com/noopkat/floyd-steinberg

I will send a pull request to @Sebastien_Mischler to include on lw.canvas-filters I’ve got it working on my local copy

@Jorge_Robles LasaurApp as a whole is GPLv3. The admin directory is my own work, please treat it as public domain and reuse/relicense as you wish, I don’t even require attribution: https://github.com/martinxyz/LasaurApp/commit/ec82182be5e . If you’re just talking about the floyd-steinberg snippet, I think it’s too small to be even copyrighted.

Pleeeease share settings! Will put as Claudio’s finest at LW materials

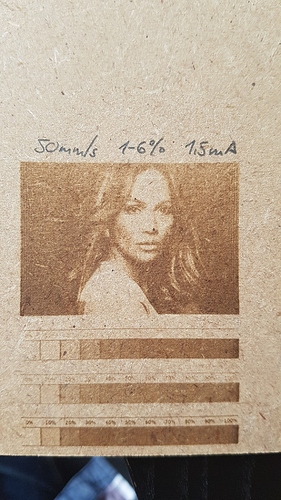

@Jorge_Robles The settings was 0.1mm laser diameter, 50mm/s, 1-6% power, ~1.5mA (als low as possible), pwm 200us.

@Bonne Wilce I was not able to do any engraving with more power on pot. I only get black coal with 10-15 mA, no matter how low I set the power % in LW. Do you have the same type of LPS?