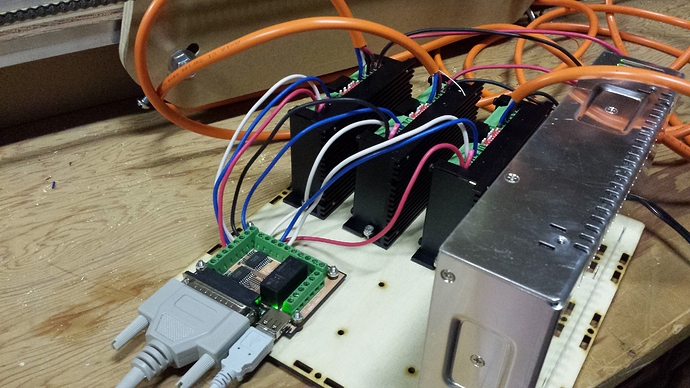

@Sue_Koran if you give us more info - type of controller, psu, endstops, etc. I’m sure we can be more helpful.

Did you buy your Workbee from Openbuilds as a complete kit? If it’s belt-fed, rather than screw you will find ‘double-belting’ makes a huge difference to reliability and ease of setup (double-belting is where you glue a length of Gates belt face-up in your aluminium channel to act as a rack-and-pinion system - you can get away with much less tension and you don’t suffer from ‘belt-bounce’).

Setting your endstop switches to NC (normally-closed) is much safer and more reliable than NO (normally-open).

Decide how you want to work with regards to 0,0 position. On my laser cutter I like my 0,0 to be top-left, but on my CNC I prefer it to be bottom-left. On the laser I have arranged that the usual X-axis is Y, and Y is X, as I do more engraving than cutting and having the lighter axis moving more in raster mode is better than having the whole x &y moving continually.

Power up your controller and download the GRBL settings and become familiar with them. Initially only change the stops, the axes and the stepping as the rest of the settings will not mean much until you are cutting.

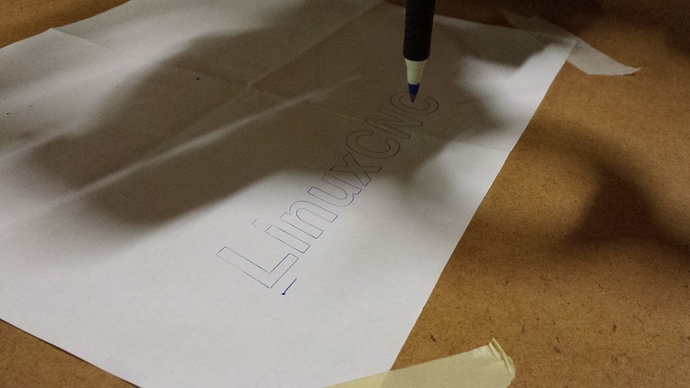

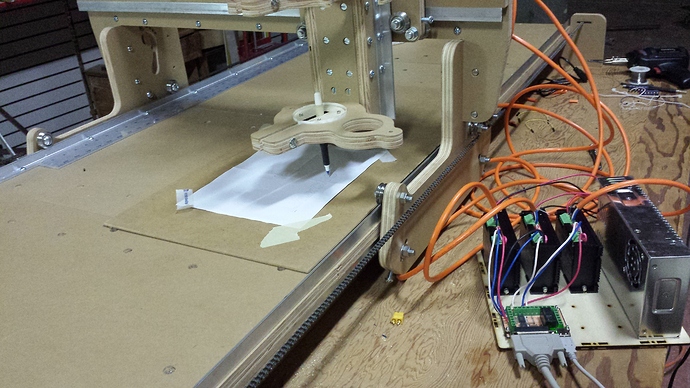

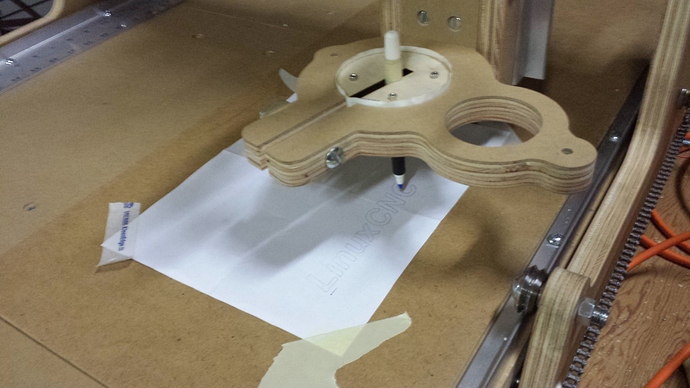

Get a digital caliper to use for calibration - it makes the job a real doddle: you tape the caliper open to its fullest extent, jog the axis up until it’s touching, zero the caliper then move a known amount (say, 20-50mm) and read off how far you actually moved. Repeat this while refining the stepper settings and you will get it super-accurate.

Work in mm, not imperial units. Most controllers convert internally from inch to mm and you always lose some accuracy as the counters drop least-significant digits going both ways and especially with arc commands, can result in out-of-round circles and curves.

Learn GCode. At least, learn the basic move and homing commands.

Save your settings to a file!