A while ago I asked here for vacuum pumps. This is how it went ![]()

A few months ago we ordered these cheap ABS cases from Aliexpress. I planned to replace the side inserts with laser-cut ones. But it turned out that the replacement was not so easy to produce ![]()

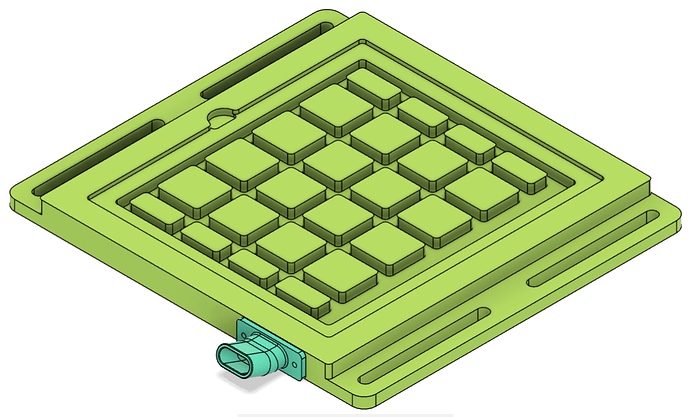

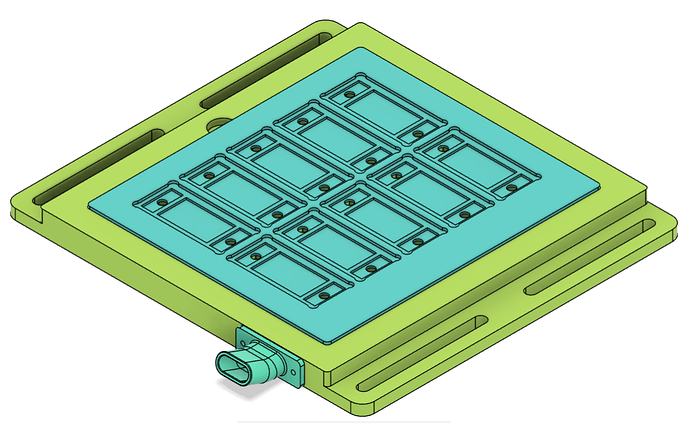

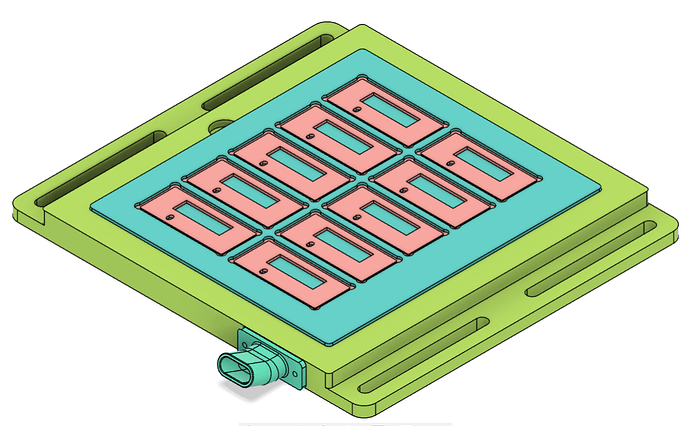

Then I jumped into designing a vacuum table. My idea was to have a base (green) and different tops (blue) to hold the parts (red) in place.

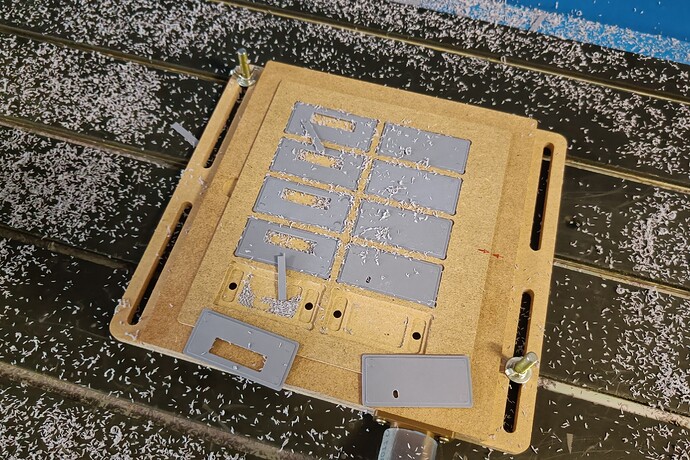

The shop vac does not like its new job ![]() But milling a set takes about 2’. So it won’t overheat. At first I expected the parts to fly around the shop. But nothing happened: It just worked

But milling a set takes about 2’. So it won’t overheat. At first I expected the parts to fly around the shop. But nothing happened: It just worked ![]()

By the way: The whole vacuum table was milled with Kiri:Moto. Also the paths for milling the inserts are done with Kiri. The Trace operation does a very good job there.

More pictures: https://photos.app.goo.gl/ALzVuDLSCWnQbxCeA

Source files (Fusion 360 and STEP):

VacuumTable_2x5.f3d (1.3 MB) | VacuumTable_2x5.step (913.4 KB)