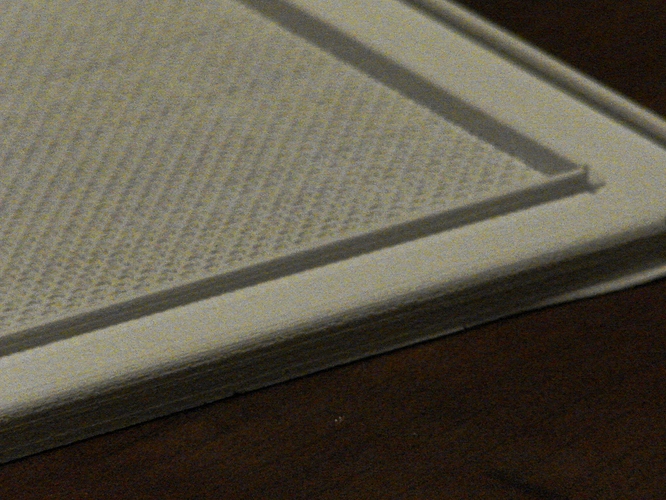

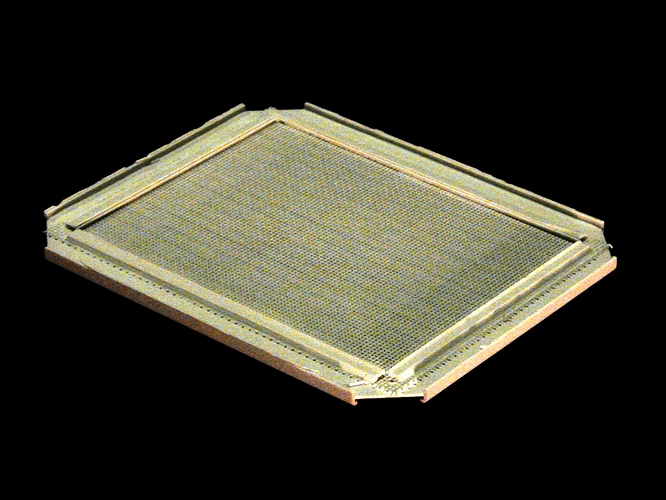

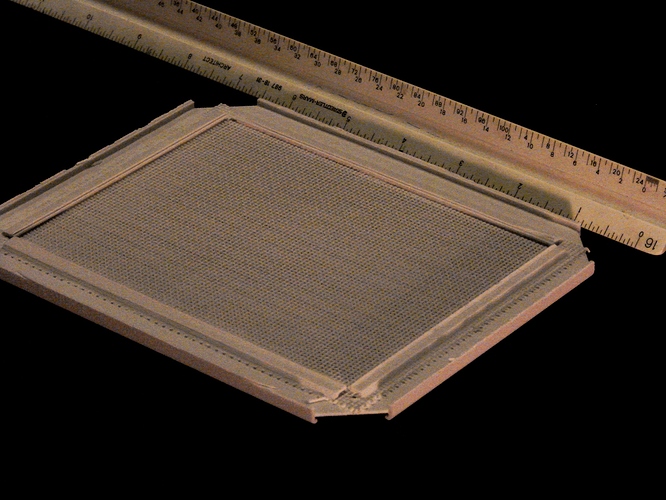

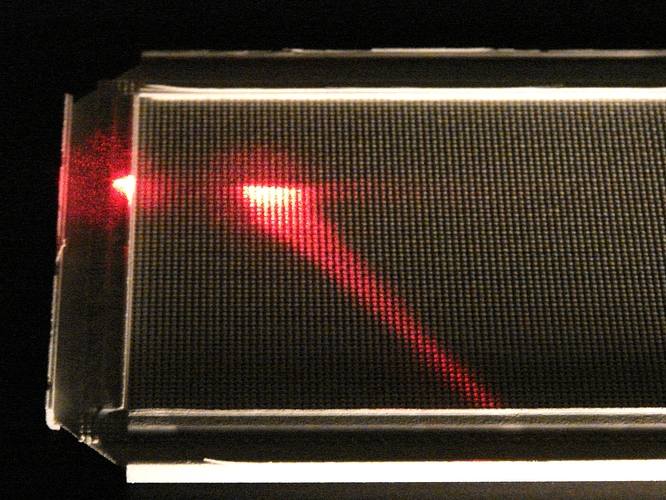

This is the smallest grid we have been capable of producing with powder based 3D printing. The binded proprietary powder can hold this matrix prior to sealing with infiltrant. This was printed from a spare HP11 cartridge, which has had plenty of use.

This community is for open-source and hobby-level printers, not commercial printers.

This is a really cool post. The mods and the ABOUT are wrong headed on this matter.

@Thomas_T_Sorensen what’s the problem about knowing what is being done out there? Should not the open-source community know its challenges?? As a famous writer said against communism: “In the name of freedom they are putting us behind bars”

I don’t know. I just know that the mods usually don’t like commercial printers

… and the reason is that we (the community) can provide analogous quality at low cost… for me it’s great to know what commercial printers are able to do, they are an inspiration, a motivation, and a challenge

I guess I am biased because I see a high emphasis on extrusion methods, but there is validity to the powder based system. This machine, by the way, is technology that is a decade old, the color capability is still 64, and that is taken off the provided color chart dated 2006.

The fact that I own a different machine with a different methodology, however, should not be a reason to exclude the maker spirit behind it.

I don’t speak for the mods, but I welcome all information from individuals experimenting with 3d printing. Spam from companies showcasing the latest high end stuff need not apply. Cheers, and thanks for sharing!

Happy to share, just an architect with a low workload here…

I think the commercial adversion is because of self serving advertising that happened at the beginning of the community, and posts like “Hi guys, I just bought a Cupcake from Makerbot, I’m one of you now” zero content posts.

But really bringing up that a process is “proprietary” is only going to ruffle feathers here, whereas it might be very effective if you were talking to investors.

The commercial aversion is just a form of elitism that is rampant in heavily opensource communities.

I have no choice but to use their powder, and their infiltrant, but it’s a small price to pay to create on one of these machines.

It is a great hobby of mine to test it’s limits…does hacking a commercial machine in this way have merit?

@Rifle_Creek no, not really. Because hacking on that machine and the results achieved is only applicable to that machine.

And @Billy it’s not elitism at all, it’s the want for these things to be open to anyone who wishes to use them. It’s not exactly for everyone if it’s a $10k machine, which uses proprietary powders, binders, technologies, etc and that in 2 years time will be replaced with a new model and no upgrade-path other than purchasing a whole new machine.

any opening is a good one my friend, it can’t be available to the masses without a starting point, and regardless, I am open to use the machine as I see fit, and will post frequently.

I doubt you would stay on your first homebuilt machine without rebuilding numerous times, right?

Nope, but my rebuilds could benefit others widely. Yours, not nearly so.

You could also say his rebuild could more valuable because it is not a dime a dozen. It could also inspire someone to look into building a powder printer which would make it super valuable.

Anthony, your point of open source value is valid.

I think the only way I can participate is to allow download of the STL file for free

Here is a link to the email needed to receive the STL file, if anyone is interested please send me your contact info and I will email you back the file.