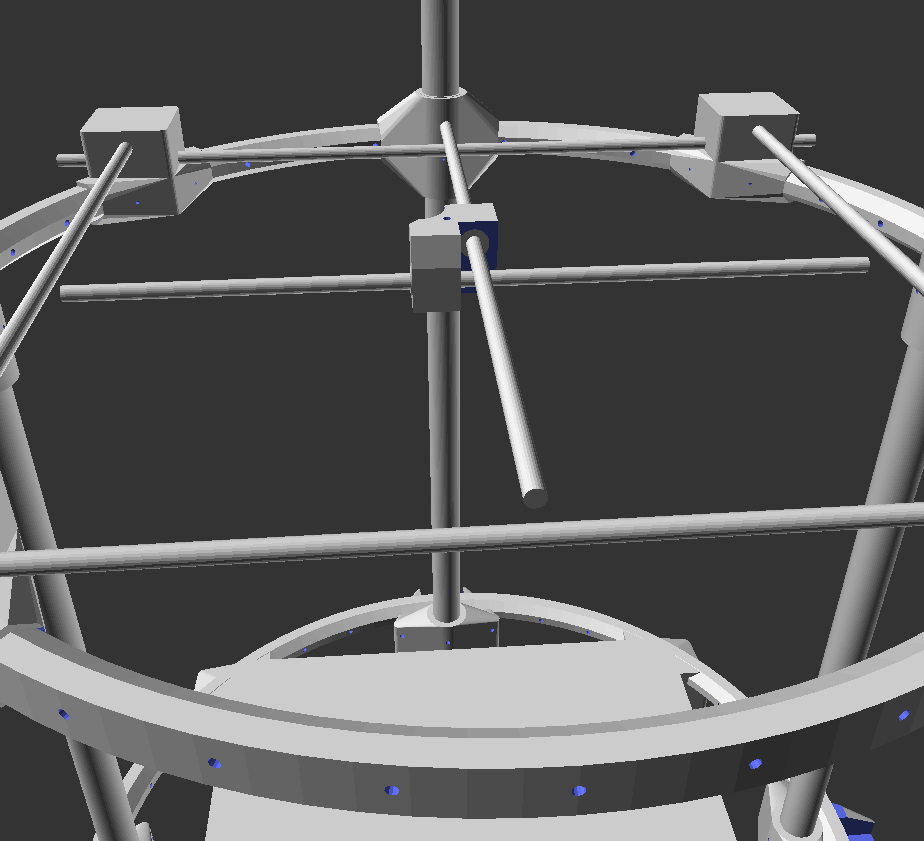

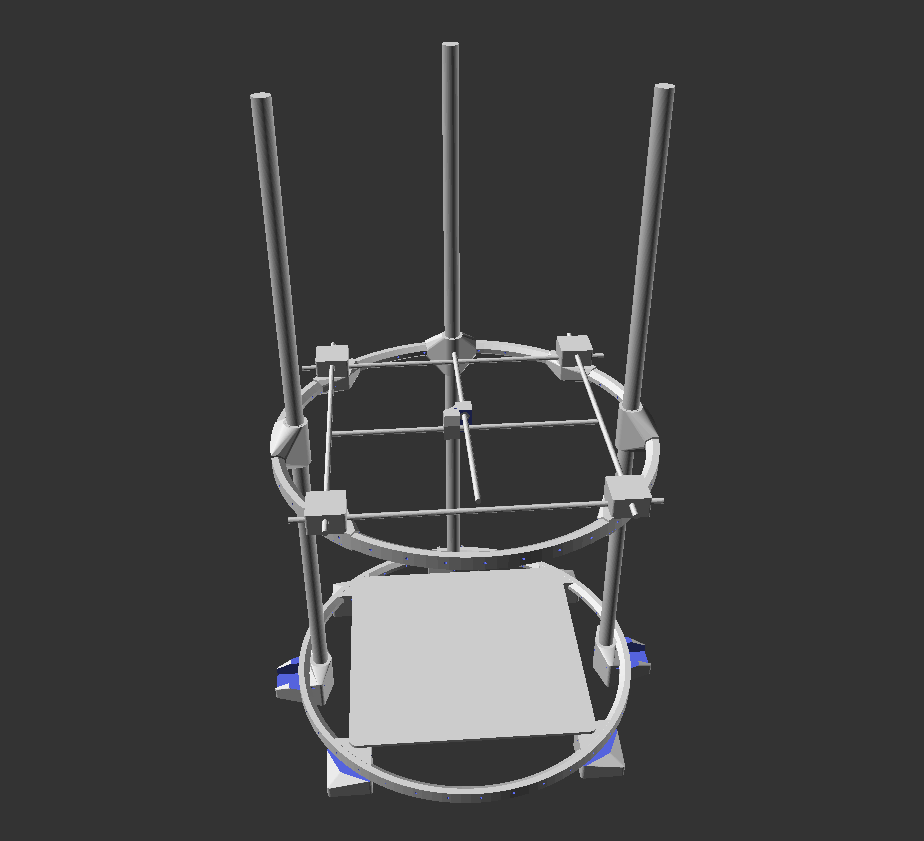

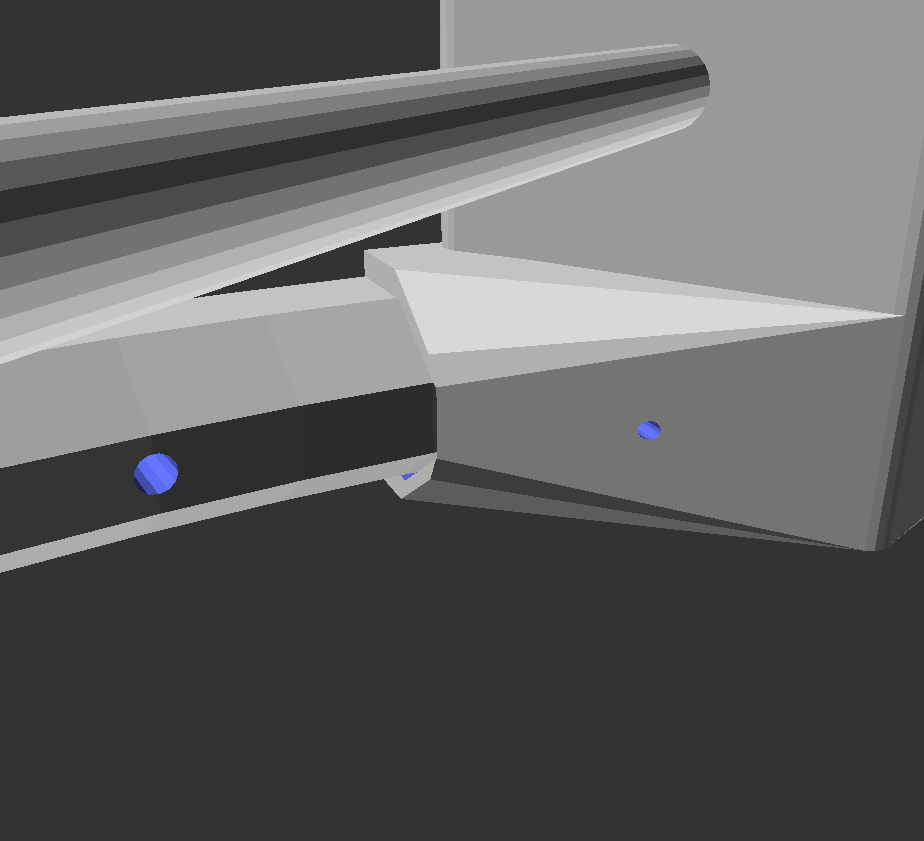

This is the current state of the reprap openscad project. It is 100% parametric.

I feel need some adjust (z no have screw and i feel is too small support)but well done real good opportunity to re-use al type of wheels

In the build file you can select 2,3,4 pillars. If you choose 3 this is what is made. If you choose 2 it will make it as you suggest.

I have not modeled the screws or the screw bracket. I also have not made the sliders. The parts need to go on a diet, as right now they would take too much plastic.

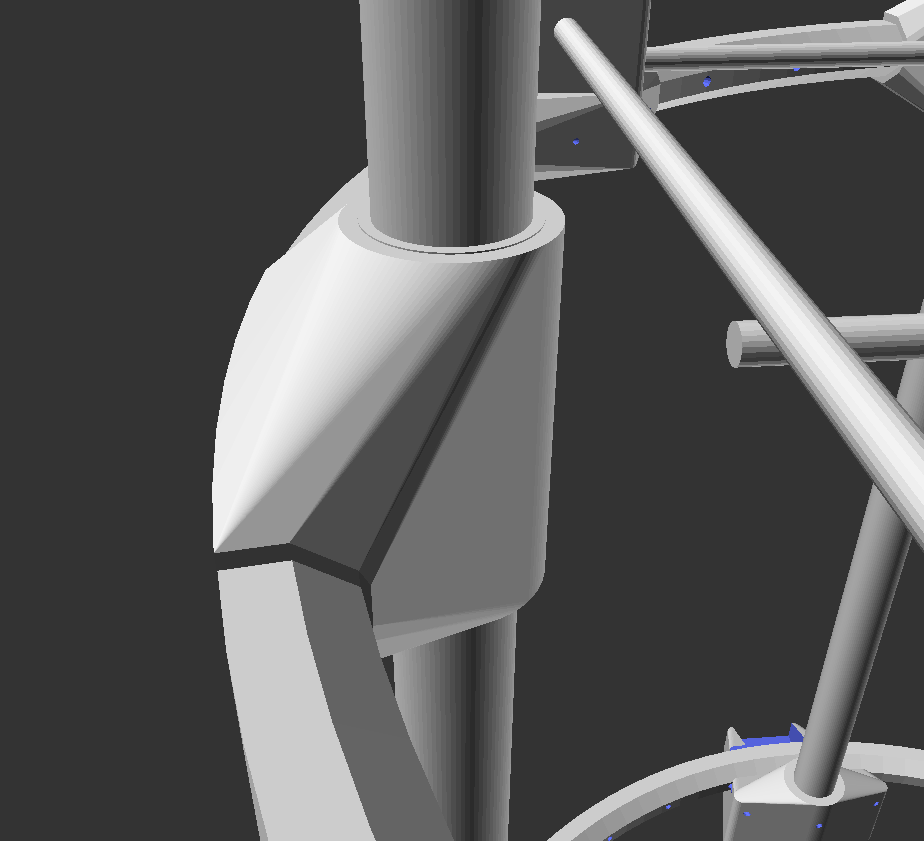

Yes, but you did cleanup on yours, my parts are huge blocks mostly

I am not worried about how solid the prints will be. Using the hull() function insures that all corners are connected through a straight line. This should make it as ridged as possible.The base pieces are huge, and the print time may be longer than i would like. But that being said, it is faster to print infill than perimeters.

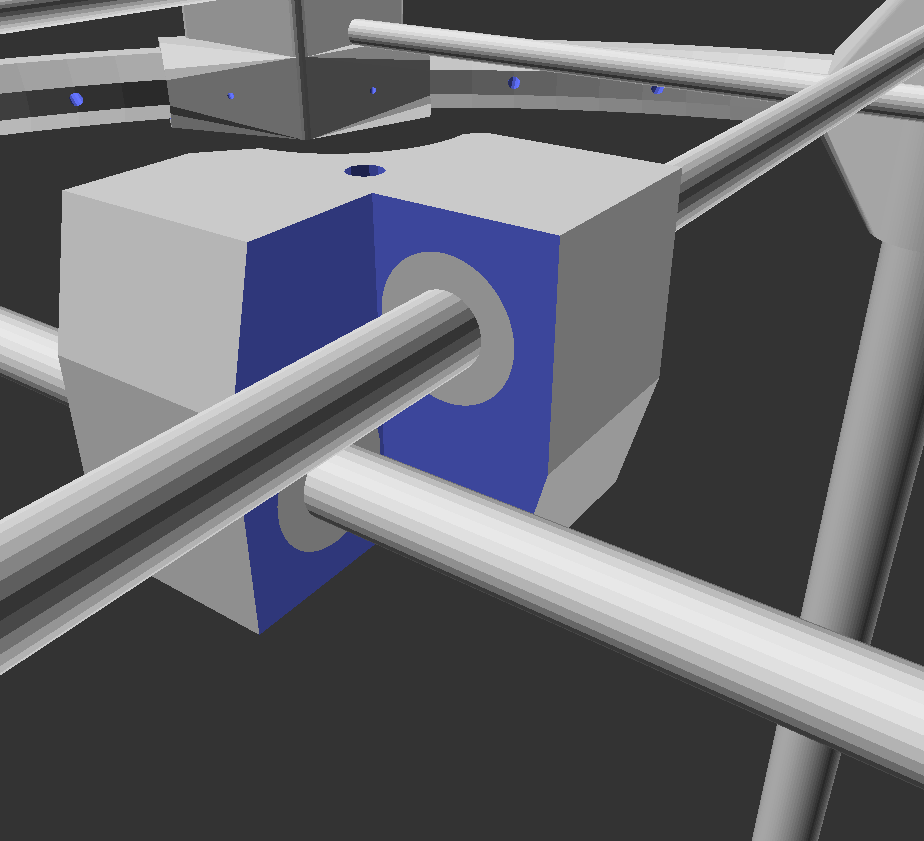

I am going to us press locking (like you did for the #VixQR )the cube will wrap 80% around the bushing/bearing. so you can press in the the object.

The boys just got 29" wheel’d mountain bikes for Xmas…wonder if they’d both miss a wheel a piece?

LOL merry Xmas, your bike is now a unicycle