Hello guys

The belt on the pulley came off, or rather the pulley dislodged and caused the belt to get trapped. Trying to release it caused the pulley and the Mount {which I now know was loose) to come adrift….

So it looks like to rebuild it I need to take the entire axis out to get access. Does anyone know of any upgrade parts (I’m in the UK). The build quality of the pulleys is poor.

Thanks in advance

Kirsty

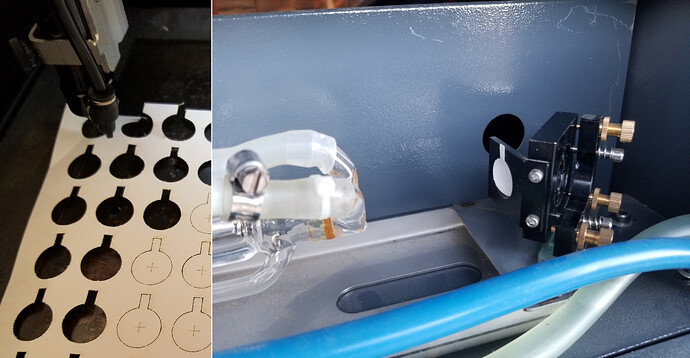

So I managed to take the axis out of the cabinet and got everything back together.

Now I’m having a big problem realigning the mirrors. Pulling my hair out ![]()

![]()

Having taken mine out and put them back there are a bunch of areas that are difficult…

Maybe you can elaborate on what you’ve done and what you think the issue is?

I found a reference was very helpful… I used a speed square to get them at 45 deg from the beam… If this are not real close to 45 from the tube beam, the beam wanders away as the distance increases. Basic geometry.

Maybe we can think of another option or a cure, hopefully, for you to try… ?

I replaced mine with a mount that will only let it be 45 deg from the mount…

![]()

Thankfully I have finally got it!! I watched so many you tube videos that concentrated on masking the mirrors and trying to hit the middle that I went crazy.

Then I happened upon John Cabrer and it clicked, we aren’t lining up mirrors so much as lining up the beam. So I forgot the mirrors and concentrated on focusing the points rather than the mirrors and got there. I feel like I’ve been dragged through a hedge backwards ![]()

However at least its done and I now am on extremely intimate terms with my K40.

Just try not to use tape over your mirrors while burning holes through it. Too many sites say to do this and its really bad for the mirror since it splatters melted glue onto the mirror and you just can’t clean that off. Better is paper or what Ive done is put a coin behind the tape so the beam can’t burn through.

Also, if you have a K40, don’t use the digital percentage meter, install a 30mA meter and watch your max current flow though your laser tube or you’ll prematurely wear the tube out. Stock tube shoudn’t be run over 18mA. See the “K40 Intro” link at the top right corner of this page.

I suggest people cut out targets that fit into their machine… I cut them out of water coloring paper… it’s thick and holds it shape in the hole. I also put a tab to get it out and know what it’s orientation was in the hole.

IMHO, As you measured yours length, it’s ~700mm, so it’s about a 30W tube and it’s maximum should only be in the 15mA range… If so, aren’t you running it about 20% over it’s limit?

Do you have a watt meter and have you measured yours?

![]()

well, I really never take it up over 80% and just slow it down as needed so maybe that’s why the tube is lasting so long.

I do not have a watt meter to measure the laser output.

I think these are much more sturdy that is normally thought…

I’d like to hear from someone with a watt meter that has measured one of these… so was just curios.

![]()