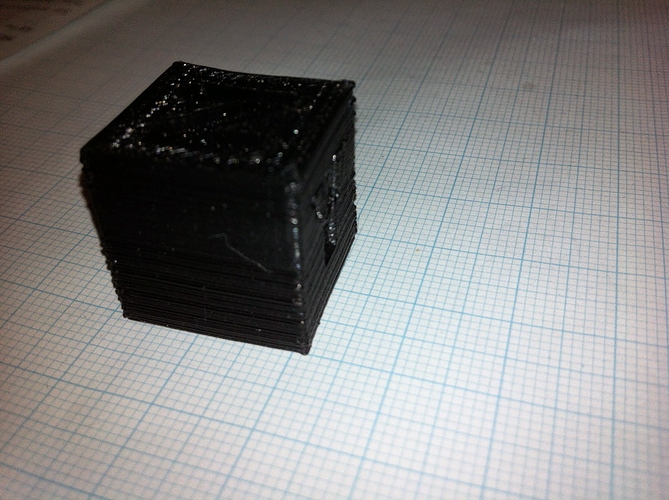

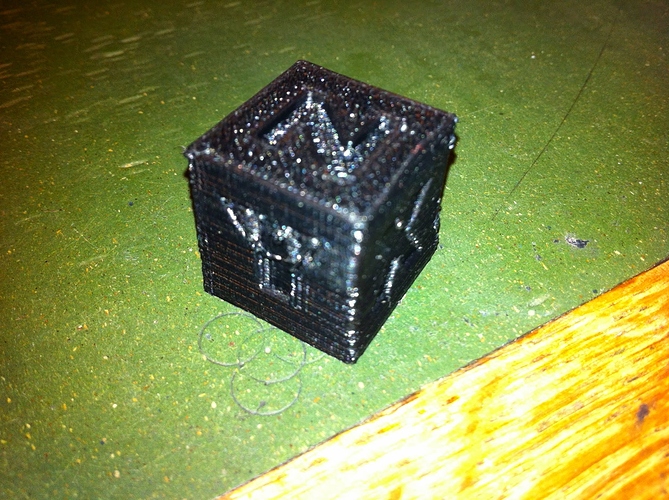

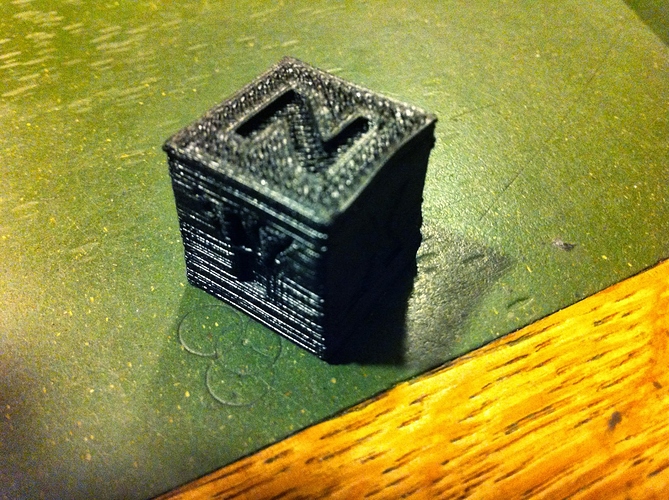

Test Cube 20x20x20mm, 200mm/s with Flint extruder, E3Dv6, 3mm ABS, 80% infill, acceleration 4000mm/s^2

It took 18min to print vs 33min with 50mm/s, same acceleration. The quality is obviously not as good as with 50mm/s but it shows that the extruder and hotend are capable of printing with 200mm/s with 3mm abs. I increased the temp from 257°C to 261° to allow better flow.

Perimeter speed is set to 40%, rest is 100%.

Wow seams hot. I used 240C when I went 250mm/s, but that is with 1.75 filament… So that night be the difference.

Also what acceleration are you running (edit never mind, I just saw it). With a time change of less than 50% from 50mm/s I think the true print speed is less than 200 especially on a 20mm cube.

Either way great job on trying high speed printing. I am tuning Herculien for this right now. But harmonics and inertia are a bitch

the printer shuld reach 200mm/s after 5 mm with an initial speed of 20mm/s and a=4000mm/s^2. So you only gain time after 5mm of each line. It also needs 5mm to decelerate to 20mm/s (I excpect). So for lines shorter than 10mm it never reaches the speed of 200mm/s. I think this explains why you save only about 50% of the time vs a speed of 50mm/s.

Anyways I think 200mm/s is to fast for my mechanics, for good quality with ABS I need to stay below 70mm/s.

I call mine “uglistruder” but it works great after putting locktite: https://plus.google.com/111479474271942341508/posts/EHSjENXvUqj

The force on the spring is quite high, I had problems in the beginning but after increasing the spring tension it works well.