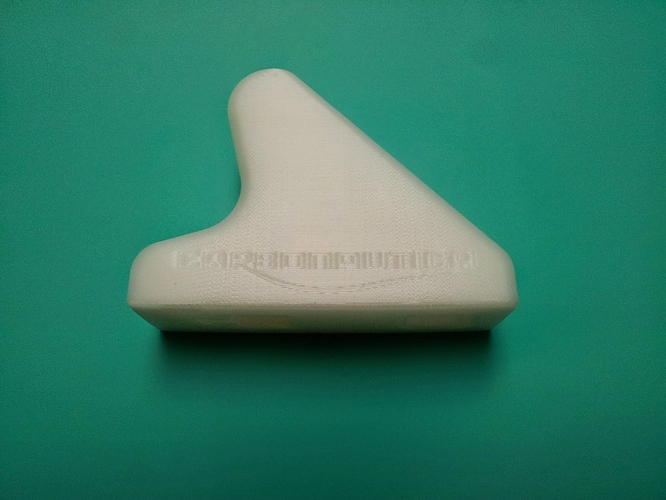

Some recent tries with E3D hotend and not so common materials. Ive finally got some time to try out the PET from http://www.plastic2print.com/eu/ and it looks wery interesting, very easy to print, good bonding and I think one can achieve nice lightning effects with this one. It comes in 0,5kg spool, completly transparent, but as you can see extrusion makes it look frosted, witch I think makes it look really cool. The other material Ive been working quite a lot these days is nylon 618, it has really wonderfull mechanical properties, and we find it perfect for rope tensioners we use on our gangways http://www.carbonautica.com

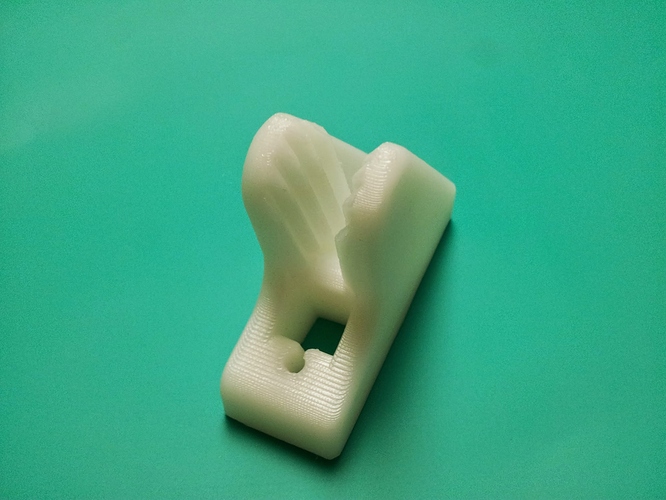

Its also interesting, there is quite a little bit of story behind this, we were milling classic three hole rope tensioners from G10, but they never worked as it should, and we could find any comercial product available to purchace for resonable price, but since the 3D printer is in house, it opened whole lot of new possibilities. So I came up with this design, and it works perfect, an I think it also looks good. Need to mention, the quantities are rather small, so we can use printing for this one becaose it takes aproximately 3 hours to make one, but since we need like only 5/week its perfect for printing.

Well, not to bore you with this stories, let me just say, I only have one problem with E3D so far, It was PLA, witch on a normal model goes perfect, but recently I got to print a housing with many holes, holders, ect. , and the E3D struggled a lot with many retracts in short amount of period. Might be I have set the retracts too much, I just leaved them like I was using them on J-head. After many retracts, it looks like PLA wants to jam in the nozzle, creating a whole lot of pressure caousing stepper skiping and then after creating really big pressure all this materail pops out creating big blob. So maybe anyone else have good tip on how to prevent this, maybe @Sanjay_Mortimer has some good advice? Im using direct drive bowden 5mm retract @30mm/s on PLA.

Other than that, happy E3D user, already applied for the 3 weeks lead time for the next one