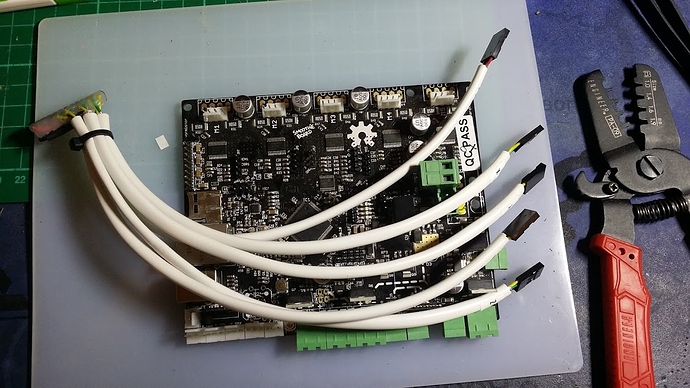

[solved] I am trying to retrofit a Smoothieboard v1.0b to a CNC3040Z CNC. I kept the TB6560 drivers and just made a cable for the dir/step/spindle/probe/estop signals. It plugs onto a 2x13 pin header that I soldered on the existing board, which simply match the signals of the parallel port (I did check more than once of course).

But I am having hard times with the config despite the nice doc.

The web server was up and OK with my old coreXY config & firmware. But I had no step signals (checked on my scope). I thought it could be due to a misconfiguration that triggered a protection meant for 3D printers (e.g. thermal protections etc). I then made lots of modifications (disabling all temps, extruders and heaters just in case), but probably screwed the config (fast blink on led 2 & 3, the other stay on).

I am using the latest “cnc” firmware. The web server fails to open, though I see my usual IP in the LAN.

Now… a cool option for me would be to get a default “brainless” config file which is pre-tailored for a generic mill. Say, the default config is really nice to start with and customize a 3D printer, but there are significant differences for milling, and I just do not know exactly what goes on below.

I am not sure about the firmware, first. Quoting from github at https://github.com/Smoothieware/Smoothieware/tree/edge/FirmwareBin: “the firmware-cnc.bin is a build for CNC using a new pendant style LCD display, requires a graphic LCD_ it also excludes modules required for 3D printing like temperature control and extruders etc. It also uses $H to home as G28 is used to park in real GCode.”_

…well… does it mean I need an LCD to run it?  Is this still compatible with “old” smoothieboards?

Is this still compatible with “old” smoothieboards?

Moreover, I wanted to be able to hack my CNC, and both the parallel port and linuxCNC will not give this freedom easily.

Moreover, I wanted to be able to hack my CNC, and both the parallel port and linuxCNC will not give this freedom easily.