So, I’ve figured out my issue with the cutting problem (i.e. not cutting cleanly). Turns out when I removed the default cutting area from beneath my perforated steel area, it dropped the steel ~4mm lower. So I raised up the legs ~4mm & now it’s cutting like a beauty.

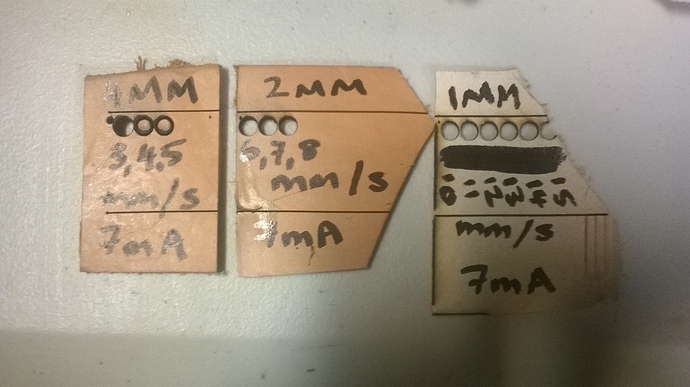

Here’s some tests I did on leather.

From left to right:

4mm Natural Vegetable Tanned Leather

Tests: 3, 4 & 5mm/s

Power: 7mA

Conclusion: 3mm/s worked, but only just. Might be better to drop to 2.5mm/s if possible.

2mm Natural Vegetable Tanned Leather

Tests: 6, 7 & 8 mm/s

Power: 7mA

Conclusion: All three speeds worked. So, I’d recommend going with the faster speed.

1mm Natural Vegetable Tanned Kangaroo Hide

Tests: 10, 11, 12, 13, 14, 15mm/s

Power: 7mA

Conclusion: All five speeds worked. So again, I’d recommend going with the faster speed.