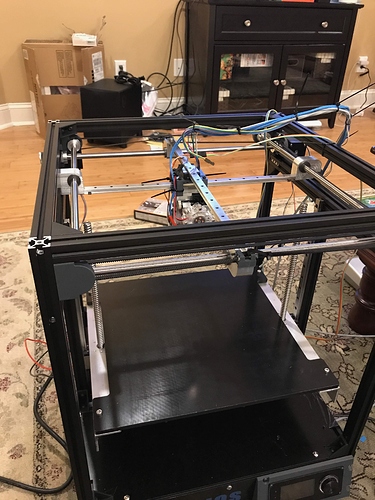

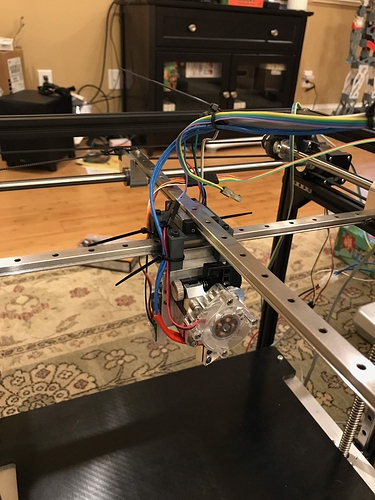

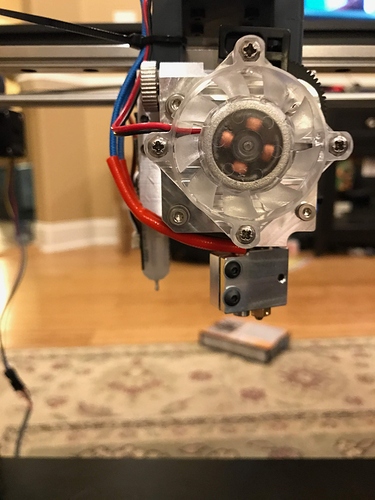

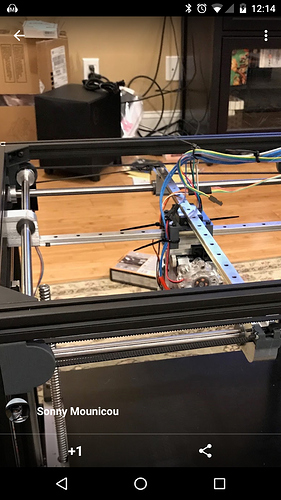

So I’m finally at a point where I have a working derivative/custom Eust. I’ll have her printing tomorrow. But I thought I’d post some pics tonight. This one has rails for x/y/z. It uses igus bearings for the rods. The bearing supports, the carriage, and the x/y ends are all custom designed CNCed aluminum. The bed is a druckerplate. On the carriage, I’m using a titan extruder with a volcano nozzle. It has a BLTouch mounted behind it. I still need to design endstops, a fan duct, and increment the x/y ends one more time. Oh, and I need to do something with wiring, its a mess.

Looking very cool. One thing I will mention is that belt path at the back will need to get straightened to be parallel with the axis. Otherwise you will fight cosine error creating differential belt tension depending on where the carriage is located along the rod.

Yeah. Thats why I need to redo those ends. I’m debating on flipping the rails sideways to get more Z. What do you think?

Neat build, thanks for sharing. I’ve been wondering why you don’t see more cross gantries with rails like that.

Don’t rotate the rails 90 degrees, if that’s what you meant. That’ll make them pretty floppy.

@Ryan_Carlyle I think because crossing gantries went out of fashion before the style of rails got popular. I decoupled the rotational and linear on mine so all linear motion is on square rails. It works very well but it requires more rails than CoreXY.

good job

Cool

please share