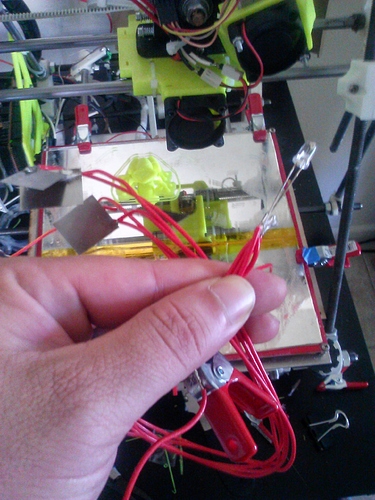

So I finally found the time to make a leveling sensor works great. 4 metal pads attached to the four corners of the build platform one clip attached to the hotend and a raspi providing 3.3 volts to blue led.

Bed is nice and level now  prints are starting to look better

prints are starting to look better

Wait … huh? How does this sense the levelness of your build platform?

Each pad gets cliped to a corner of the bed, an aligator clip is attached to the hot end, the lead from the hot end is hooked up to 3.3v from the pi and the pads ground. You heat the bed, and move the extruder to your first pad.

I used the one closest to me on the left, lower the z axis until the led is solid not flashing. Move to the other three coeners and adjust the bed leveling knobs until the led is solid, do this at least two times (without moving the z axis) and your bed will be level.

Worked great for me.

Simple and elegant. Nice!

Yes it is. Sadly I can’t take credit for the idea. Ill have to find the link to the thingiverse user

Although his uses a paizo buzzer instead of an led.

I’ve been thinking a little about this recently. If you’re using a Mendel design you could drive the two z motors slightly to account for variations in height during the print. Just measure many points on the bed say with a simple removable microswitch, use that to create an elevation map of the bed and use that to drive the head up and down slightly during the print.

Automatic bed levelling is high on my list of requirements for my next printer. Looking for a good h-belt design still.

I actually found a good h belt design ill have to see if i can find the link.

In theory its posible to do that with this type of setup. Z axis would need a max endstop then it would lower until the hot end conacts the pads it would then probe the other three and compensate on each corner while printing.

prints are starting to look better

prints are starting to look better