Ok my z axis seems to get messed up when cutting. Or at least it works until a certain depth or complexity. I’m trying to cut a circle that has holding tabs CAMBAM put in. It goes along just fine until about 6mm deep. It seems to not step down to 7mm, but thinks it has. Then when it gets to the tabs it moves up, but doesn’t always move back down, yet thinks it has. There is some text it is supposed to write as well, usually it writes it way above the wood. Tonight it was trying to move the bit while it is still in the wood. What could be wrong? Is it not getting commands? ie the buffer is empty or full? Machine malfunction? The z axis moves just fine when jogging by itself. I can provide the gcode if helpful.

Probabaly binding or your driver’s are over heating

Make sure your drivers are set to be always on, if they lose power the holding torque just is not there, and the Z axis will drift

You didn’t mention anything about your mechanical or electrical setup, so I’m assuming its a stock type Ox Z axis assembly, probably running a (pthew) TinyG. There are several possible causes in order of probablity:

-

The lead screw is loose in the axis. This is usually caused by the setscrew on one of the leadscrew lock collars coming loose or shifting. Usually caused by accidentally running the axis into the end stops. Firmly grip the router mount and try to shake the Z axis up and down. If it moves at all, you hear a click, or feel slack in the axis, it’s loose.

-

You are losing steps on the Z axis motor. Could be due to a loose wire, bad driver, weak motor, or binding on the leadscrew from a bad bearing or lead nut. With the power off, you should be able to manually move the Z axis up and down with some effort. Manually rotating the motor coupling should be easy and not feel gritty.

-

As Anthony pointed out, the Z axis could be drifting down due to the weight of the router if you do not have the motor drivers set to at least 50% holding current. Make sure the enable lines are connected to the drivers from the Arduino, the $2 parameter is set to 255, and the motor enable is, well, enabled. This is less likely since it does not coincide with what you said. This would likely cause the axis to cut deeper than it was supposed to, not shallower.

-

Driver overheating, as Julius mentioned. Low probability, but depending on what kind of drivers you used, it is possible. Just stick your finger on the heatsink. If you can hold your finger on it, it’s not overheating. If you burn your finger, reduce the motor current settings or stick a fan on it.

Highly unlikely that it’s anything wrong with the arduino, software, or communications since this would affect all the axes, not just Z.

MG

Back lash is the last thing to add to the equation if a standard lead nut was used instead of an anti backlash nut

I have about .020 of backlash because of the nut and the weight of the spindle… I compensate for it in my designs

I had a very similar problem and it was the set screws. I replaced the small set screws with hex screws that you can get tighter and the problem disappeared. It doesn’t take much of a slip for the motor to turn without lifting or dropping the Z axis. I have also had trouble with the X and Y set screws and have changed all of them. Since then the machine has been very true.

Hmm I’ll look at all of this. Yes this is an Ox with Tinyg. I can jog it without a problem, but maybe I’m just not seeing it. And it’s not under any load. I have the tinyg’s motors all cranked to the max, I’ve felt the driver chips and it doesn’t feel too hot, but I’ll check all that too.

You won’t see anything in jog unless your eyeball is calibrated to a few thousandths of an inch. Grab the router and haul up and down on it rapidly. If you feel or see ANY movement, likely your lock collars are loose.

MG

So I tightened my nuts, all were tight. Changed the power to always on and it helped. Also moved the potentiometer on the Tinyg for the z axis to halfway. It wasn’t off by too much this time. But still off enough.

I can move my router up and down when I grab it…at least before I turned the motor always on. It moved but it turned the screw. I think it may have been partially binding before. I had the essentric spacers set so it was fairly hard to move. And my z axis is a NEMA17.

@Nick_Portelli Glad your nuts are tight, Nick. 8]

I think you are still missing the point of the router jiggling exercise. Yes, with the power off, you should be able to move the router up and down slowly, using quite a bit of force, causing the screw to turn. That’s fine.

What I am getting at is a rapid shaking of the router up and down. The objective is not to turn the screw, but to see if there is any slack or play in the Z axis. If you can feel any small movement, hear a clicking sound, or see any play in the axis while rapidly trying to shake the router up and down, that is your problem.

Also, you didn’t mention that it was a NEMA17 motor. That could be your problem right there, as it may not have enough torque to move your router weight. You may be losing steps going up but not down, which will cause your Z axis to lose position. I never recommend a NEMA17 for any CNC. While they are fine for 3D printers, they just don’t have the needed torque for CNC.

Also, cranking the pot on the stepper driver blindly is not the correct way to do it. There should be a set of instructions for setting the current using a multimeter. There should be a calibration constant relating Vref and motor current. There is a test point on the board to measure Vref. It is important to set the motor current to the value specified in the motor specifications. Getting too far out of the window for current setting will usually cause the motor to malfunction. Too high is just as bad as too low. Don’t guess at settings!

Set the eccentrics so you can turn the wheels with your fingers, and they have a fair bit of resistance. If you can’t turn the wheels individually with your fingers, they are too tight, and if they spin freely, they are too loose. You want to be halfway in between those two extremes. Also, if you built the machine yourself, check to make sure you don’t have an extra precision spacer or missing precision spacer on one of the wheels. This will cause things to bind up big time.

In addition, lubricate your lead screw with some silicone spray lube, or dry spray lube. DO NOT use plain WD40! WD40 will cause the extreme V-wheels to crack. Spray some dry lube on a paper towel and wipe down the wheels and tracks once in a while to clean them and ease movement. Dry lube (like used on guns) dries out but still provides a lubricating film and does not attract dust.

Something like WD40 Specialist Dry Film Lube, DuPont Teflon Non-Stick Dry-Film Lubricant, or Hoppe’s No. 9 Dri-Lube.

Sorry for being so long winded.

MG

No I understood what you meant, I tried and there was none. I’m about to go and play some more, so I’ll try again and double check. I’m only explaining everything I do because I am such a noob at this. I’m a programmer by trade so that side of it isn’t hard to understand.

I didn’t upgrade to the NEMA23 because I thought that the designers would know if it could handle the spindle…which is a 400 watt version.

The only instructions I see for the tinyg and setting the pots is on their wiki. I’ll go through and do that. But from what I recall it did not involve a multimeter.

@Darrell_n your instructions and advice much appreciated. There was nothing in the instructions I got saying how to actually set the spacers…at least that I can recall. I did build the machine myself and the instruction seemed lacking. I was worried about the z axis because it didn’t seem to fit well together. I don’t think I missed any spacers, but I’ll go back to the newer instructions and see if I did it correctly.

No please be long winded, I have a lot to learn. I wanted a machine I could build and tinker with…but maybe not this much.

I do recommend upgrading to nema 23 motors, you will have less issues in the long run.

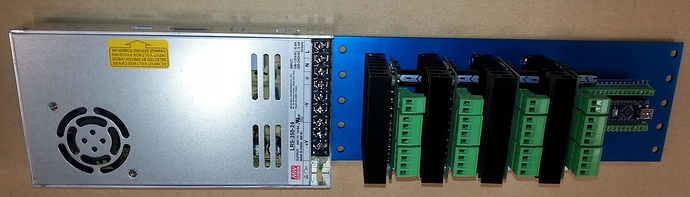

@Nick_Portelli Are you using a 12V or 24V supply? 24V would be much better torque wise. Your TinyG wouldn’t be able to put out the full current needed for a NEMA23 motor. It needs 2.8A according to specs, I run mine at 3A just because. TinyG is only good for 2.5A.

After doing a bit of research, I just found a bunch more reasons to hate the TinyG. They use the DRV8818 driver chips, which have kind of an odd current setting algorithm. Normally, on a plug in driver board like the Pololu A4988, there is a pad (Vref) on the board that is used to set the motor current. The pot is wired from Vcc to ground, and the higher the voltage on the pot wiper the higher the motor current. The wiper is attached to the VRef terminal, so you just put a meter on the Vref and the current is something like Vref*2 or some similar relationship.

Synthetos didn’t do that. Their pot setting instructions go something like “if the motor doesn have enough current, turn up the pot. If the motor has too much current, turn down the pot” This is completely ridiculous. There is no way to actually determine what the motor current is. You just blindly tweek the pot until it somehow magically “works”. Total and utter bullsh*t.

Also, there is no way to put a heatsink on the DRV8818. It is supposed to be heatsinked by a thermal pad underneath the chip, but if the board isn’t designed properly the chip will overheat and go into shutdown. Best you could do is put a good little fan blowing directly on the board to remove as much heat as possible. Perhaps some stick on heatsinks on the chips themselves might help as well.

As you can tell, if you have seen any of my other posts, I have an extreme hate on for the TinyG board. You couldn’t get me to use one if they paid me to.

So, back to the matter at hand, if you have no play in the axis, it is likely that the motor just isn’t cutting it. (pun intended). Use 24v, a fan, and some heatsinks on the chips and crank up the current a bit, see if that makes it better or worse. Go to a NEMA23 if you dare. I don’t know why the original OX design called for a NEMA17. Doesn’t make much sense unless you have a Dremel for a spindle.

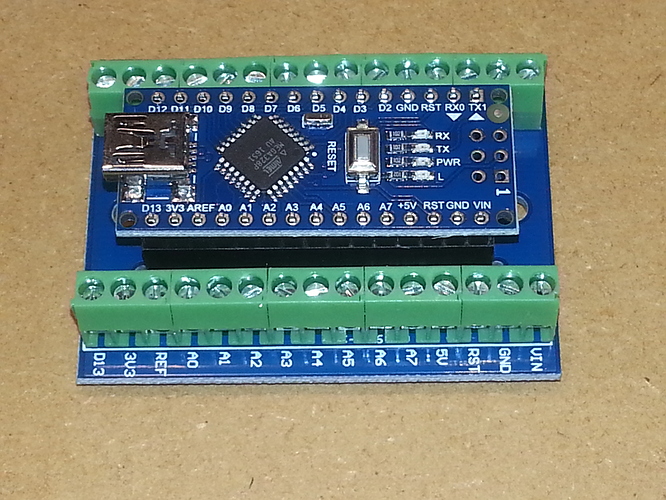

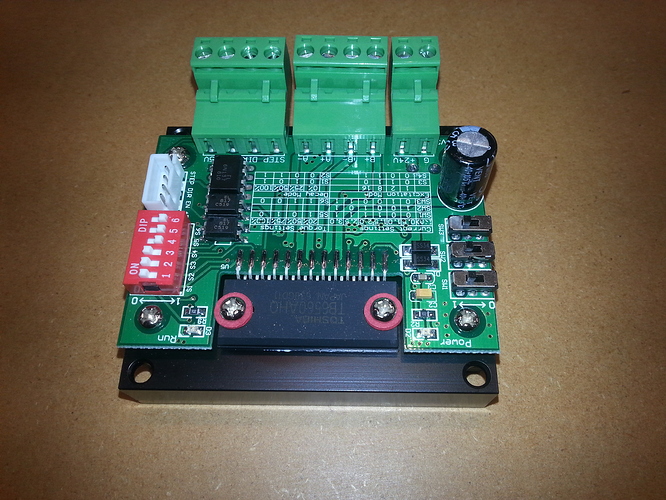

If that doesn’t work, buy a $5 Arduino Nano, a $5 screw terminal motherboard for it, and some Sainsmart TB6560 stepper drivers and wire up your own driver system. Cost you 1/4 of what the TinyG does, and you can update your own GRBL software instead of sending your board back to Synthetos to upgrade theirs. And, you’ll have a MUCH more robust, reliable, and repairable system.

And don’t worry about the Noob thing. We were all noobs at some point. Fortunately, it wears off…

Well I don’t hate it yet, mainly because I don’t really know what else is out there. Or what would be a good replacement. But I get what you mean about setting the current, when I first read the instructions I thought that a little odd and expected a more direct way to know what’s correct. And I believe I’m running 24volts.

So for other boards you are suggesting a Arduino? I have a few UNO’s is the nano the same just smaller? And you load GRBL software onto it? Or do you have other suggestions for boards that are decent for beginners?

@Nick_Portelli Yep, a standard Uno will work fine. I used to use an Uno with screw terminal shield, but the Nano is just easier to use and more compact. Same processor and I/O layout. I load GRBL using a small free program called Xloader. Go to my website http://3DTechWorks.ca and have a look at the Blog. Everything you need to know is in there.

MG