Recently went looking for a replacement of a stock K40 laser head for the K40 at my local maker space. I was surprised to find out that there was a slightly different design being sold then I was use to seeing. Seems like these came out maybe a couple of years ago?

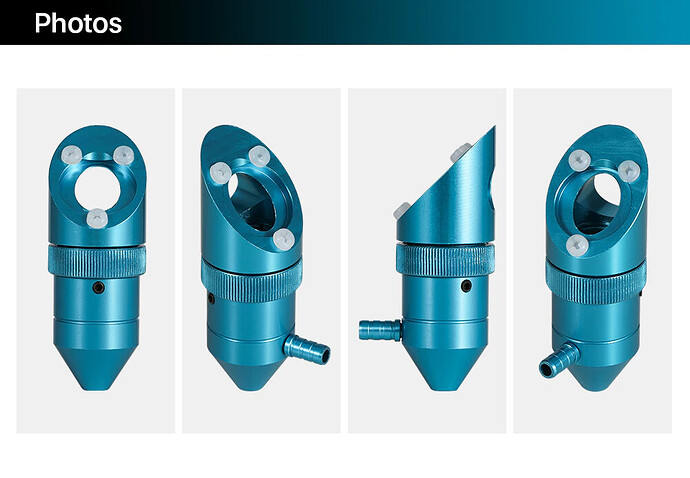

The most obvious difference is in how the mirror is retained. Instead of the metal clip there are 3 plastic (nylon?) screws. You do have to be careful not to cross thread them.

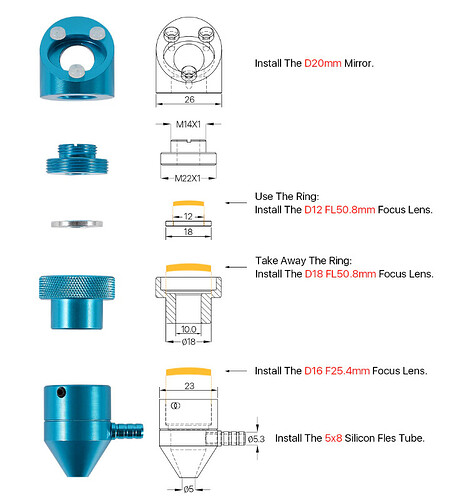

The really big difference is that it allows use of either a 12mm, 16mm or a 18mm lens all with the same head.

I got a really good price from the Cloudray store on Aliexpress

https://www.aliexpress.us/item/3256801332491652.html

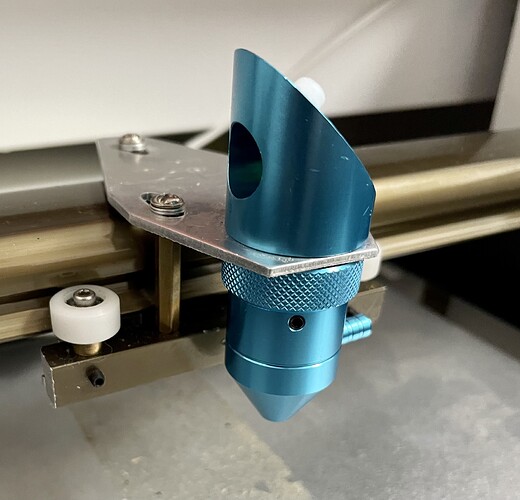

It arrived today and I got it installed. If you get one just note that there are 2 set screws holding on the air nozzle when you first go to take it apart. You will only be able to tighten one of the set screws after you get the head mounted to the plate, which I guess is why there are 2 screws.