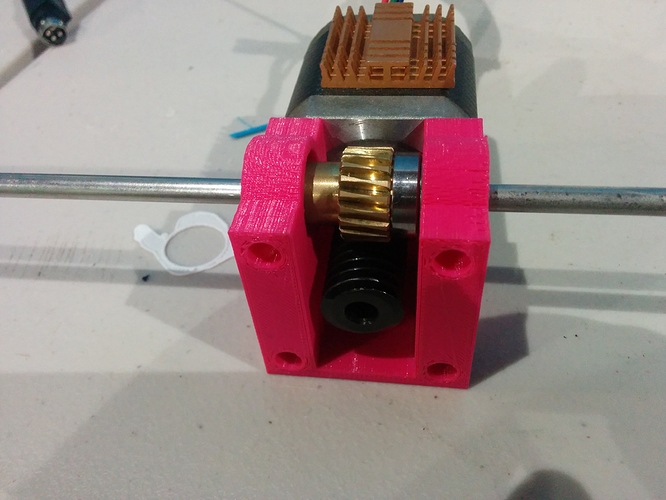

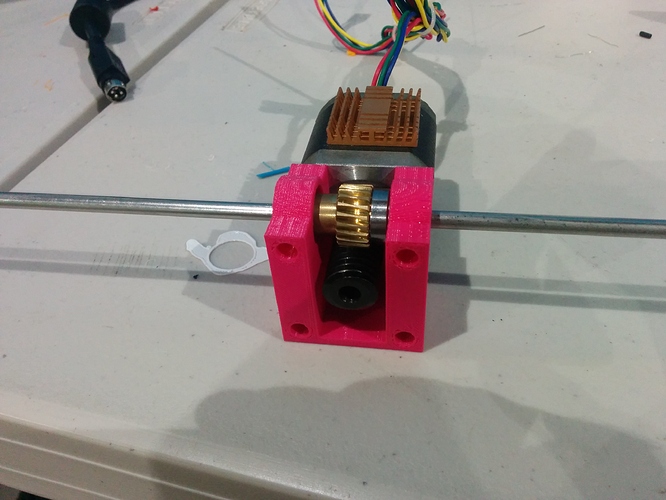

My solution for a dropping bed. 1:10 worm gear, with a 5mm stainless rod that goes across the entire bed. Keeps everything in sync, no lash (though it took quite a few adjustments and prints to get it that way!), 1 motor, and I can flip it and hide it away under the machine once I extend it.

I like the look. I have always wondered how belt stretch will effect a large moving bed. Sometime I put a lot of force on the bed pulling off a pesky print.

That looks pretty good. Where did you get the worm gear ?

+1 for the heat sink too. I do this to all my steppers now. I found some cheap and tall north bridge heatsinks that work great. Just add a tiny dab of thermal epoxy and you are done.

http://www.ebay.com/itm/321344353749?_trksid=p2059210.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT and http://www.ebay.com/itm/321344351604?_trksid=p2059210.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

darn, ebay is blocking the links… at least for me… anyone else has that problem ?

At that price, It certainly does look like a good solution to the problem. It looks like the seller has a limited supply. I wonder what general availability is.

I really like this. Looks like belt driven z is more feasible with this.

The worm shows a 6mm ID. Did you use a NEMA 23 and take the shaft down to 6mm?

@Matt_Miller , 5mm ID, 6mm OD brass tubing used as a shim currently to shore up the diameter. Can be found at hobby shops.

Good call. Ordered the stuff tonight as a fall back if my initial idea for a belt-driven Z doesn’t pan out.

How heavy is your bed?

Worm drives need lube, lots of it.

I’m wondering if you’ll need any custom tuning to account for lash in the system for vertical travel. Kind of the opposite of z-lift on a delta.

I mentioned my lathe having a lot of lash. The compensating mechanism to account for that is to always cut in one direction, and when changing cuts, pull the tool far enough away to take up the lash, plus the distance for the new cut.

Just dropping the plate the height of the layer may introduce z artifacts due to wear, lubrication anomalies, and stitction…moving it down 1mm+z-height, then back up 1 mm might give more consistent prints.

Unless it’s perfect…then game on!

Looking forward to seeing it in action!

Still haven’t had the time to go lathe a shim for this.

how’s your bed looking now days?

Nonexistant. Been too busy with life.