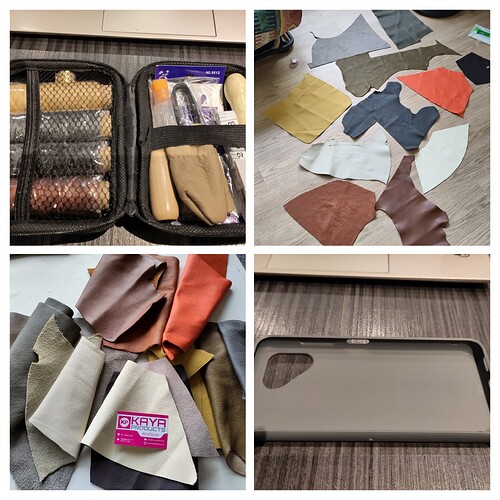

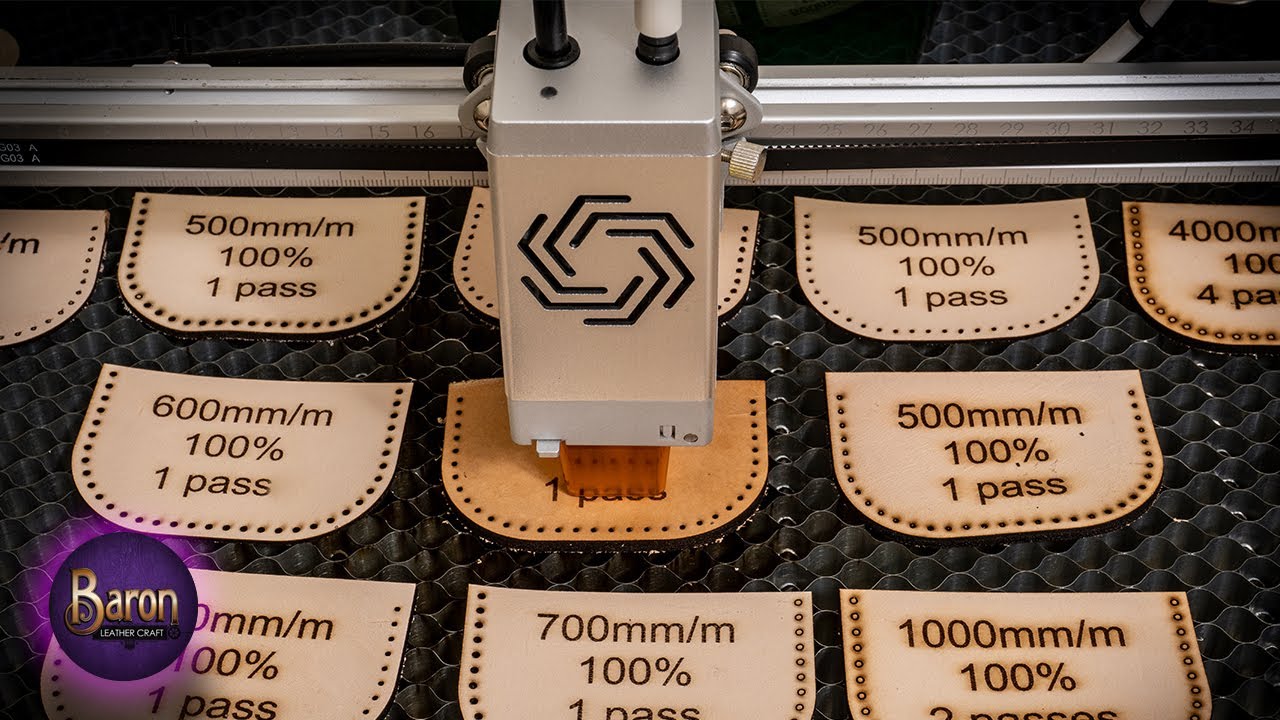

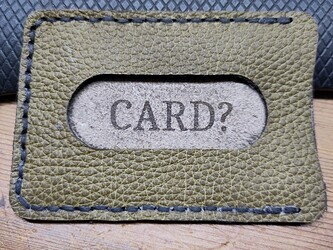

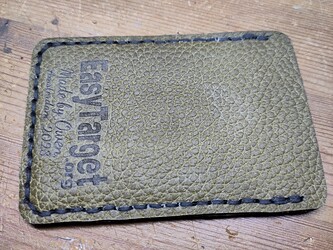

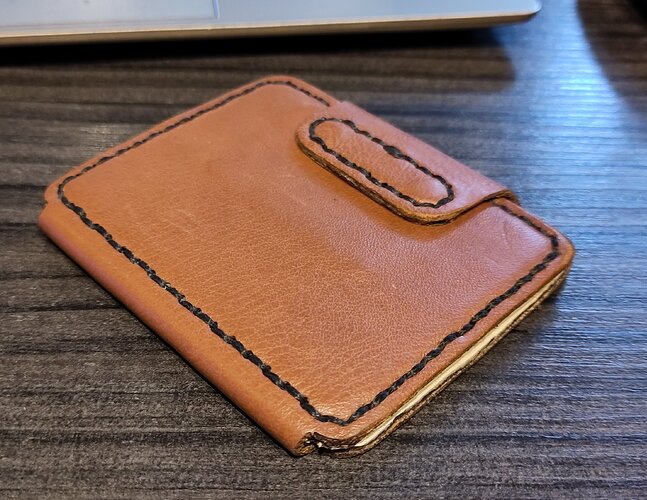

You can see all the elements I want for my Mobile Phone flip-case in here; it has hinges, a closure, inserts and I also experimented with cutting, cleaning and stitching techniques while making it. I’m also getting a feel for the different leathers I have.

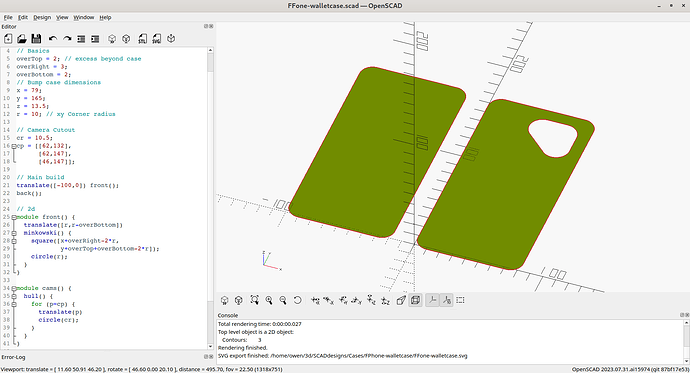

cardflip.scad

// Leather CardCase

$fn=90;

// all following in mm

card=[53.98,85.6]; // standard ccard size

crad=3.18; // standard ccard corner radius

pad=10; // top padding

stitch=3.5; // stitch padding from outside & inside

pitch=5; // stitch pitch

pin=0.7; // stitch hole diameter

loop=[10,card[1]+2]; // loop size (base)

hinge=4; // reduce loop width on inner hinge

closure=[36,card[1]]; // closure flap (base)

magnet=5; // closure magnet diameter

// Compute these here for convenience

centerO=card[0]+(2*pad)+(4*stitch)+loop[0]; // outer

centerI=centerO-hinge; // inner

centerF=-(card[0]/2+closure[0]/2+2*stitch); // flap

topF=(closure[1]/2)-(closure[0]*0.75); // flap loop centers

// Inner Leather

color("green")

difference() {

// basic outer shape

union() {

panel();

translate([centerI,0])

mirror([1,0])

panel();

translate([centerI/2,0])

square([loop[0],card[1]],center=true);

}

// strap cutouts

translate([centerI/2,0])

for (y=[1,-1]) {

translate([0,y*card[1]/2])

scale([(loop[0]-hinge)/2,(card[1]-loop[1])/2])

circle(r=1);

}

// Cutouts on either side (mirrored)

for (a=[0,1]) {

translate([a*centerI,0])

mirror([a,0,0]) {

// holes for stitching

stitching();

// Slit

translate([card[0]/2+(pad*0.33),0]) {

for (y=[-1,1]) {

translate([0,y*(card[1]/2)])

circle(pin*2.4);

}

square([pin/2,card[1]],center=true);

}

// Thumbslide

hull() {

translate([6,0]) scale([12,16]) circle(1);

translate([-10,0]) scale([12,30]) circle(1);

}

}

}

}

// Outer Leather

translate([0,card[1]*-1.5])

color("slategrey")

difference() {

// basic outer shape

union() {

panel();

translate([centerO,0])

mirror([1,0])

panel();

translate([centerO/2,0])

square([loop[0],card[1]],center=true);

// Closure flap

translate([centerF,0])

flap();

}

// strap cutouts

translate([centerO/2,0])

for (y=[1,-1]) {

translate([0,y*card[1]/2])

scale([loop[0]/2,(card[1]-loop[1])/2])

circle(r=1);

}

// Stitching

for (a=[0,1]) {

translate([a*centerO,0])

mirror([a,0,0]) {

stitching();

}

}

// Flap Stitching

translate([centerF,0])

flapstitch();

}

// Flap inner

difference() {

hull() {

translate([centerF-closure[0]/4,topF])

circle(d=closure[0]/2, $fn=45);

translate([centerF-closure[0]/4,-topF])

circle(d=closure[0]/2, $fn=45);

}

translate([centerF,0])

flapstitch();

//translate([centerF-closure[0]/4,topF])

//circle(d=magnet);

}

// Internal Stiffner

translate([0,card[1]*1.5])

stiffner();

// dummy card

if (!true) {

color("gold",0.5)

minkowski() {

square(card-[2*crad,2*crad],center=true);

circle(crad);

}

}

module panel() {

minkowski(){

union() {

square(card,center=true);

translate([pad,0]) square(card,center=true);

}

circle(stitch*2);

}

}

module stitching() {

for (x=[-(card[0]/2):pitch:(card[0]/2)+pad+pitch]) {

translate([x,stitch+(card[1]/2)]) circle(r=pin,$fn=18);

translate([x,-stitch-(card[1]/2)]) circle(r=pin,$fn=18);

}

for (x=[-(stitch+(card[0]/2)),(stitch+(card[0]/2)+pad)],

y=[pitch*0.5:pitch:(card[1]/2)+1]) {

translate([x,y]) circle(r=pin,$fn=18);

translate([x,-y]) circle(r=pin,$fn=18);

}

}

module stiffner() {

minkowski(){

union() {

square(card-[crad,crad],center=true);

translate([pad,0]) square(card-[crad,crad],center=true);

}

circle(crad);

}

}

module flap() {

difference() {

translate([closure[0]/4,0])

square([closure[0]/2,closure[1]],center=true);

translate([0,closure[1]/2])

circle(d=closure[0]);

translate([0,-closure[1]/2])

circle(d=closure[0]);

}

hull() {

translate([-closure[0]/4,(closure[1]/2)-(closure[0]*0.75)])

circle(d=closure[0]/2);

translate([-closure[0]/4,-(closure[1]/2)+(closure[0]*0.75)])

circle(d=closure[0]/2);

}

square([closure[0]/2,closure[1]-closure[0]],center=true);

}

module flapstitch() {

for (y=[pitch/2:pitch:topF]) {

translate([-stitch,y])

circle(r=pin,$fn=18);

translate([-stitch,-y])

circle(r=pin,$fn=18);

translate([(-closure[0]/2)+stitch,y])

circle(r=pin,$fn=18);

translate([(-closure[0]/2)+stitch,-y])

circle(r=pin,$fn=18);

}

for (r=[-70:70/1.5:70]) {

translate([-closure[0]/4,topF])

rotate([0,0,r])

translate([0,(closure[0]/4)-stitch])

circle(r=pin,$fn=18);

translate([-closure[0]/4,-topF])

rotate([0,0,r])

translate([0,-(closure[0]/4)+stitch])

circle(r=pin,$fn=18);

}

}

If I make more of these I’d probably extend the hinge piece on the outer shell by 1mm (on X) to make the hinge apply a stronger closing effect. And extend the neck of the closure by 2 or 3mm to allow the magnets more overlap, and use stronger magnets.