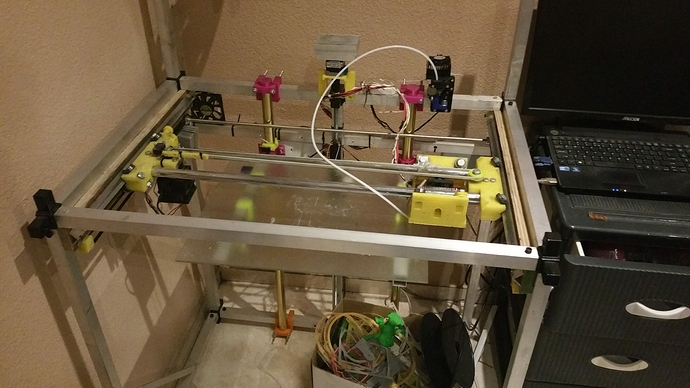

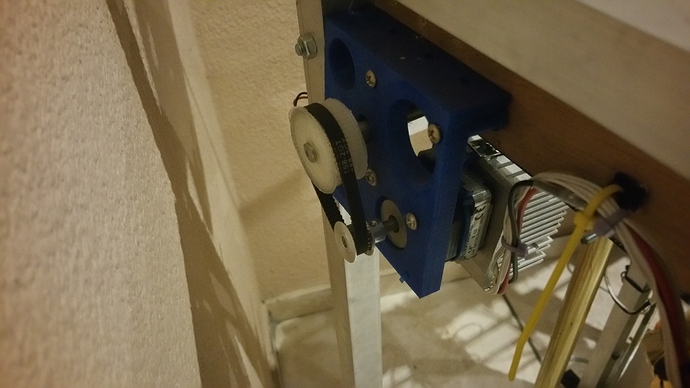

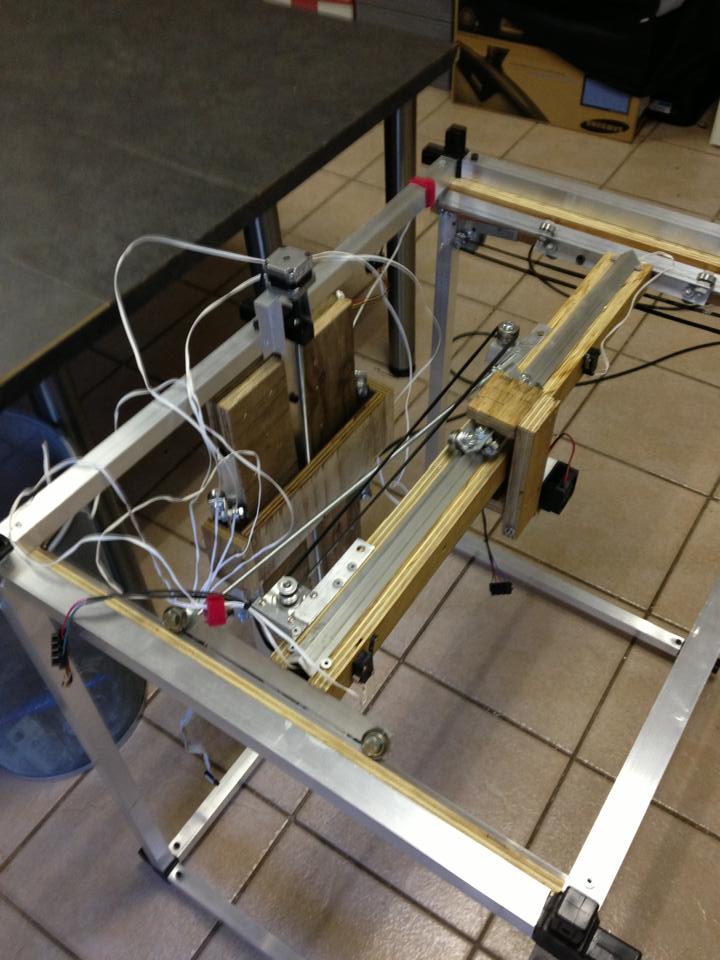

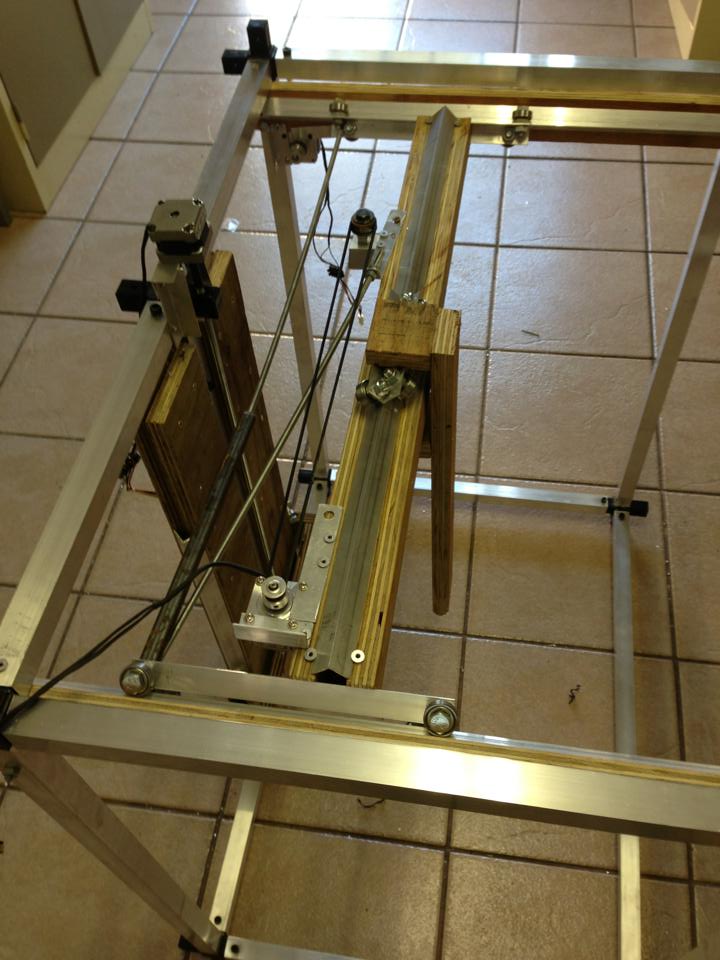

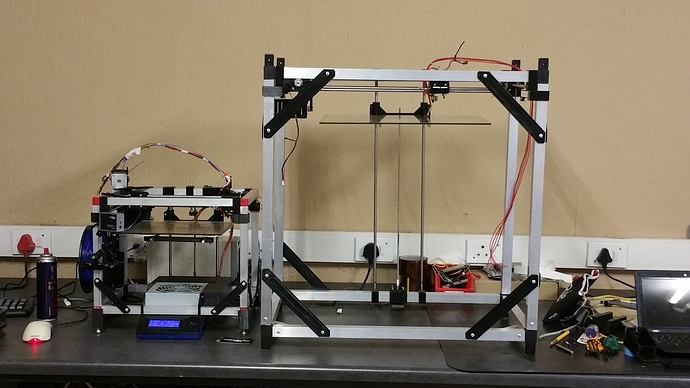

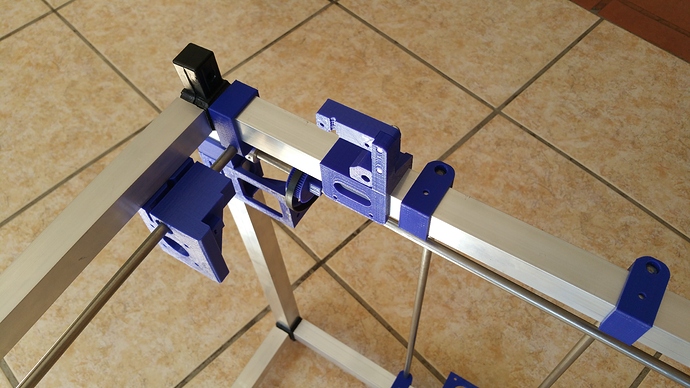

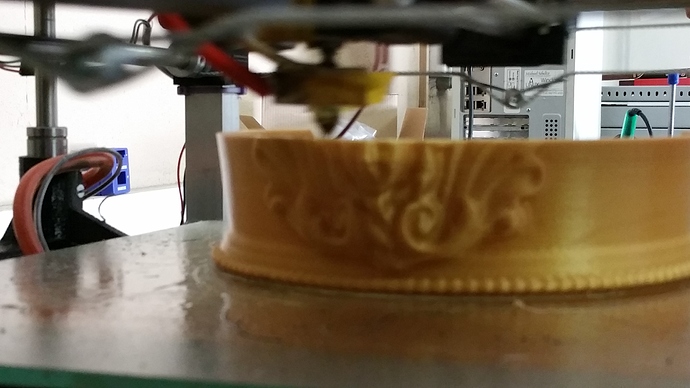

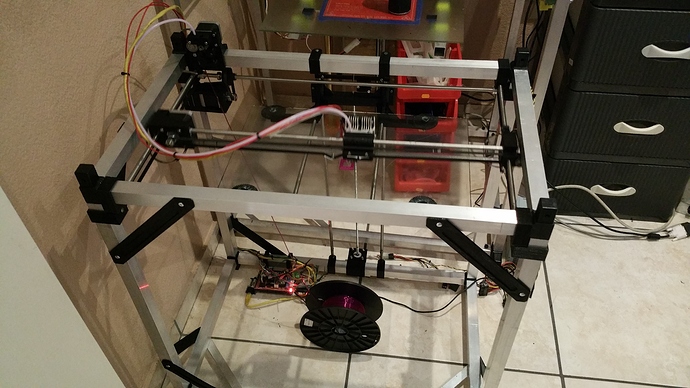

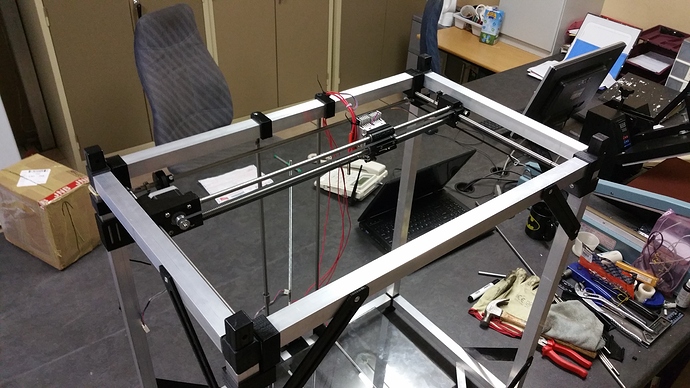

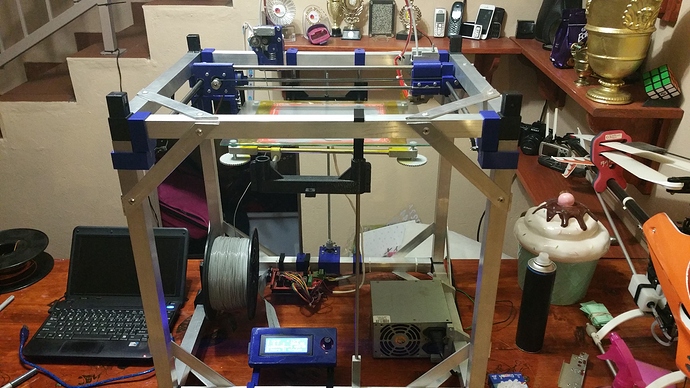

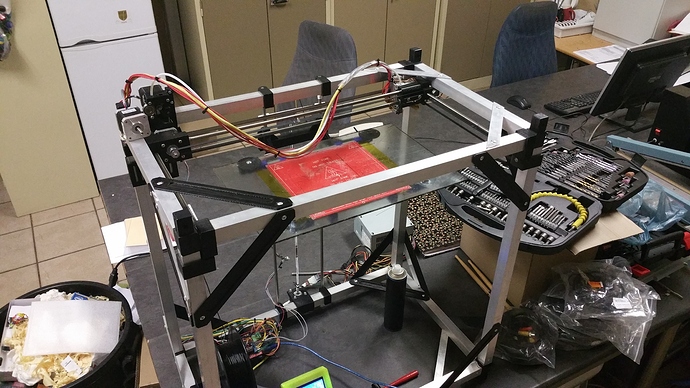

My history of printers. You will note my first printer was as strapped as a repstrap can get. And it’s 1st prints reflected that once I got it dialed in however 1st job was to print better parts for itself. To where the printer was printing parts that was really good. It was ably to print pulleys that held onto a t2 belt without slipping pictured in the one with the belt drive for the small steppers to cope with a heavy gantry. It then printed parts for the 2nd little printer mainly because I felt that if something broke on the big printer it would suck to have to go back to the wooden gantry parts to reprint a repair part. The little printer just performed like a champ it can print the nasa wrench over and over and they all work. Logically if that works bigger is better so need a big one and I upscaled the design for a bigger machine and then found it didn’t work as well. That would be the 4 gen on my printers after bracing it more it actually does print well but I wanted better. So the 5th Gen I redesigned the shortcomings of the 4th Gen built it and from the 1st print it just blew my expectations away. I actually printed a nasa wrench pictured before I calibrated the printer. It works but I had to change the steps on the one axiz by a fraction to get it right and the gantry wasn’t perfectly square so I had to adjust it. My journey is far from done but it was nice to get a compliment from someone that works with stratasys machines daily that I would not get the quality prints I have without spending what my house cost.

When can I get blueprints for this / ones like it

The belts are nearly silent the printed gears wore out and where noisy.

Mine never work, I can’t seem to figure out some one golden key to making my printers actually produce something more than a hot mess - congrats!

@Nathan_Walkner , gear reduction, mounting options (can mount motor inside frame instead of hanging off the side)

@Michael_Anton don’t use abs, and keep at it. It took me 6 months to get it right. I’m also extremely self critical any flaw in printing drives me nuts till I solve it.

Pla doesn’t start deforming till way over 100’C if your motors are melting it you have too much current going through them. On the big machine I put heatsinks on them to keep them cool but since then I’ve started using bigger motors now and they are hardly warm to the touch. I printed velocity stacks for a car that sits on the intakes and they don’t melt. People say abs is stronger than Pla but it’s like stainless steel is harder than mild steel, they’re both bloody hard. I’ve printed Car parts that sit in cars and don’t melt ( and I live in South Africa it gets hot here) including a cellphone holder that sits on my steering column to keep a phone in line of sight for navigation apps.

?? blueprints

+Nathan Walkner If hadn’t just boiled my kettle and seen it for myself I would argue with you till the cows came home. It is however direct heat, but it does indeed bend. I’ve always used a heat gun but this will be handy.

If the ambient temp is over 100* f outside and you leave ABS in the car it will start to melt. One of the grand kids left a printer in their car at work and after a few hours the ABS deformed pretty badly. PLA would have done worse. I’ve only had a PLA heat issue with earlier Wades designs and i2 gantrys. I’ve got a a few machines that have seen heavy duty cycles that are all PLA that are between two and three years old.

@Jay_Turner I’ll still post the rest here is the extruder so long. https://www.youmagine.com/designs/redsalamander-s-extruder Posting a full printer design is rather daunting. there have been so many revisions that compiling the latest parts is a little tougher than 1st thought.