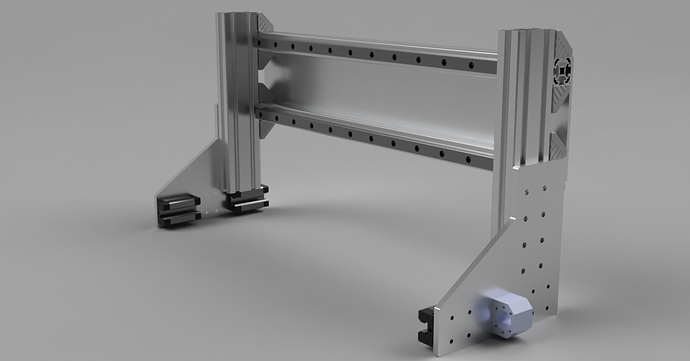

MY DIY CNC milling machine project - Redesigned the gantry.

Altered the design using two 40x40 mm alu profiles where I can mount the two Bosh Rexroth 25 mm rails (X-axis).

I`m going to use two 45mm Boshh Gussets in each end to mount the 40x40 profiles to the side profiles.

Then I plan to mount a 6mm aluminum plate on the rear side of the 40x40 profiles.

Hope this makes a stable Gantry for my CNC

Like this

missing/deleted image from Google+

looks legit You’re using real linear guides so just about anything should work.

The 40x40 profiles I`m going to use - stronger than the profiles used in the 3D model

missing/deleted image from Google+

I suggest to mount your X axis bearings facing down(below the table) and not to the side. Protect the from shavings and dirt. You can stiffen things up by having another gantry below the bed, unless you need the clearance to have 4th axis parts expend below the height of the bed.

@Marcus_Wolschon most of the frame is ready, including the z-axis, so it’s too late to modify the design like that

Okay. Then there should be an enclosure around the spindle and guide-rails.

@Marcus_Wolschon Agree, I’ll try to find a way to do that

With a screens guarding the rails and a good dust collecting system, it is not necessary to mount bearings below table.

Such muting, will higher the CG of the gentry which is not recommended if precision is important.

I’m going to use these in combination with a 25pin serial cable between the control unit and CNC for the end stop wiresmissing/deleted image from Google+

And 4pin 16mm aviation plugs for the stepper motor wires. Separate shielded wires for each stepper motor.missing/deleted image from Google+